1 / 5

Fully Automatic Box Making Machine

| Model No. : | Zt-003-269 |

|---|---|

| Brand Name : | Zhongtuo |

| Power : | 4KW |

Cangzhou, Hebei, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

- Video

Product description

Fully Automatic Box Making Machine

Box coil plate is cut in the transverse shear unit of length steel plate, the general packing boxes are loaded into the form, 0.8MM thickness requirement is COLD ROLLED SHEET, size is 1M X 2M means, 0.8mm thick, 1m wide, 2m long cold-rolled plate. Commonly known as the hot box plate is sized packing boxes of hot-rolled sheet.

Finished products:

Thickness:0.5-1.0 mm

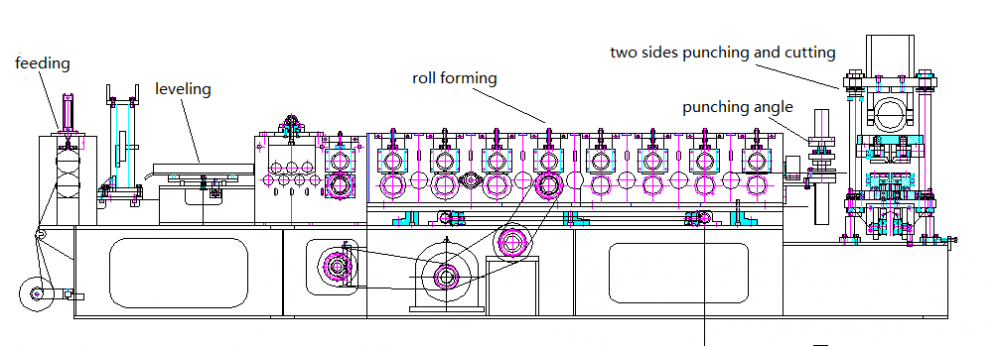

Roll forming machine production process

Decoiler - feed - leveling - roll forming - punching angle - shear and folding - output table

Working speed: speed: 8-12 m/min;

Decoiler

1 Coil inner diameter:450-550 mm

2 Max coil width: 1250 mm

3 Carrying capacity:5000 kg

4. Working method: manual loading

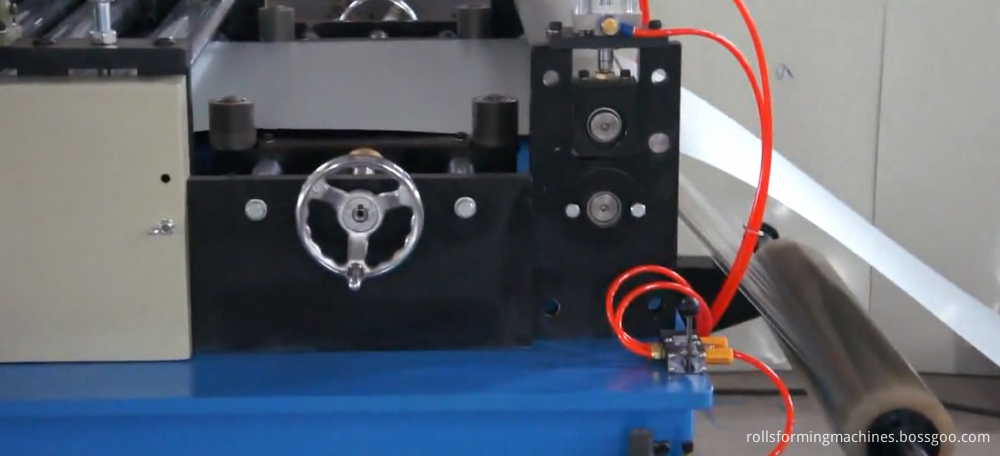

Feeder and leveling

This part will level coil to make sure it is neat clean and straight. Leveling uses 7 rollers, 3 upper rollers and 4 down rollers.

Feeder rollers: two sets

Roll forming machine

Size(L*W*H) : around 5.0 *1.5 *1.0 m

Power: 4kw

Forming roller station:10

Roller material:45 # steel after finishing quenching HRC 58-62 ℃, chrome plated

Shaft material:45 # steel finish

shaft diameter: ¢ 50 mm

Voltage:380V, 50HZ, 3 phase( customize)

Transmission: 1.0 chain

cutting and bending machine

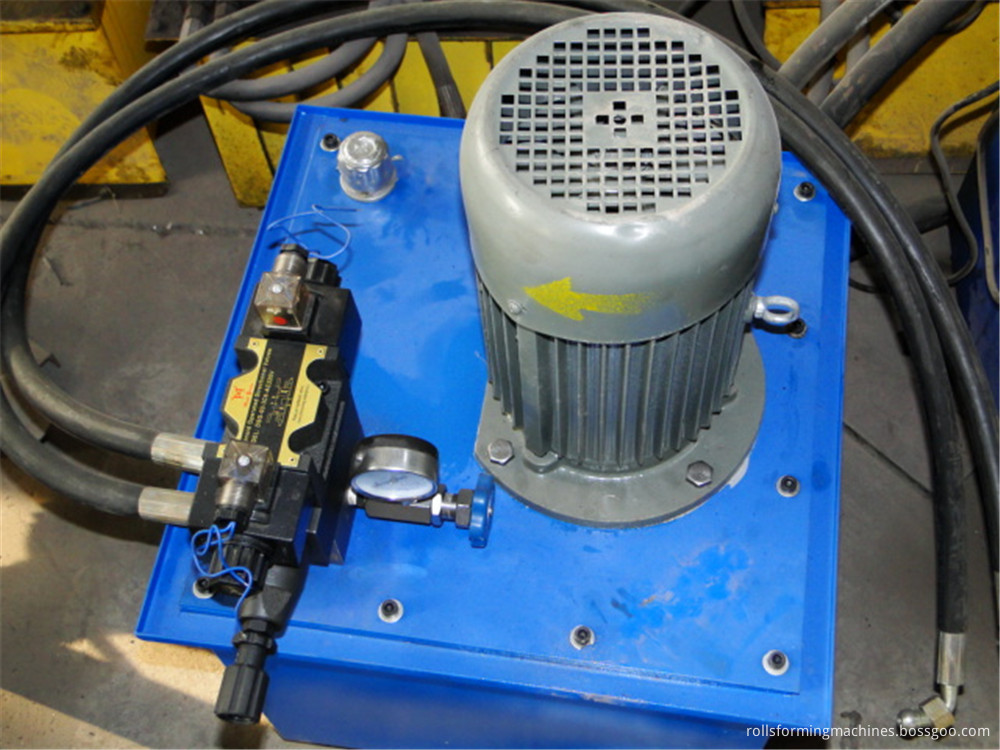

Hydraulic Station

Combined by oil pump, hydraulic clique, etc.

Hydraulic power station:5.5 kw

Hydraulic pressure:16 Mpa

Hydraulic oil: 46#

Electric Control System

(1)Brand:Panasonic PLC

(2) Automatic control length cutting counting.

(3) computer-controlled length and quantity control device stops.

(4) Modify length error

(5) control: touch screen and buttons coexist

(6) Unit of length: millimeter (length dimension on the touch screen)

output table

It adopts welded steel and supported roller to transmit the products.(2 sets)

Cangzhou, Hebei, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

- Video

Send your inquiry to this supplier