1 / 1

Full Automatic Block Production Line with Curing Rack "U" Type (QFT(10-15)

Get Latest Price

Send Inquiry

| Model No. : | Full Automatic Block Production Line |

|---|

Qunfeng Intelligent Machinery Co., Ltd.

You might also like

Product description

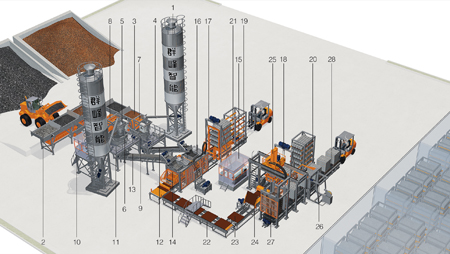

(1) Cement Silo

(2)Batching Machine for coarse material

(3)Batching Machine for surface material

(4)Screw Conveyor

(5) Cement Scale (including Water Scale)

(6)Concrete Mixer

(7)Pigment Mixer

(8)Mixed Material Transit Hopper

(9)Mixed Pigment Transit Hopper

(10)Control Room for Mixer

(11)Mixing Platform

(12)Belt Conveyor for Pigment

(13)Belt Conveyor for Raw Material

(14) Block Making Machine

(15)Center Control System

(16)Auto. Color Feeding System

(17)Elevator

(18) Lowerator

(19)Automatic Block Loader

(20)Automatic Block Unloader

(21)Cured block conveyor

(22)Horizontal Pallets Conveyor

(23)Transit pallet conveyor

(24)Pallet turnover

(25)Green block conveyor stopper

(26)Automatic Cuber

(27)Tray Bin

(28)Tank Type Conveyor

Qunfeng is a China- based manufacturer of full automatic production line with curing rack. We offer a vast range of products that include roof tile forming machine, concrete batching machine, block making machine, waste processing equipment and others.

1. Description:

The full automatic block production line with curing rack includes an automatic scaling and batching, Automatic mixing, automatic molding/block producing, elevator and lowerator, curing, wet and cured blocks Conveying, automatic stacking, pallet turnover and recycling, cured block packing systerm. It requires 5 Workers.

2. Configuration:

1)cement silo 2)batching machine 3)screw conveyor 4) cement scale 5) coarse material mixer

6) pigment mixer 7)mixed material transit hopper 8) mixed pigment transit hopper 9) mxing platform

10)belt conveyor for pigment 12) block making machine 13) computer control system

14) auto. Color feeding system 15)elevator 16) lowerator 17) automatic block loader

18) automatic block unloader 19) cured block conveyor 20) pallet -stop machine

21)ladder pallet turnover 22) cuber conveyor 23) cuber 24) tray bin 25 loader 26 forklift

3. Features:

1) Uses proportional electrical and hydraulic control relief valves, which automatically adjust the oil flow and pressure as per specific working requirements, to buffer the hydraulic cylinder when working; Uses integrated high-pressure and soft oil pipes, with easy installation;

2) Use special design of fixing table and knock type vibration, improves the speed of making product and the accuracy of the size of product.

3) Heavy-duty machine frame, which uses high-intensity steel and advanced heat treatment, is wear resistant.

4. Note:

1)Curing room, steel track, workshop and other supporting equipment should be supplied by the buyer.

2)All kinds of mold can be made per the customers drawings.

Further more information&pictures, please contact with our company

Send your inquiry to this supplier

Send Inquiry