1 / 1

Folding steel mesh storage cage

Get Latest Price

Send Inquiry

| Model No. : | Folding steel mesh storage cage |

|---|---|

| Brand Name : | Wuhao |

Fujian Wuhao Industry & Trade Co., Ltd.

You might also like

Product description

Specifications Folding steel mesh storage cage

1, Mesh cage design.

2, For material handling, transport, storage

3, Foldable, stackable

Brief description of folding steel mesh storage cage Hard working, returnable wire containers deliver high visibility savings. Handle, transport and store bulk parts and material the efficient way. Perfect container for in-line assembly work or work-in-process operations. Fully collapsible and stackable 4 high. Folding steel mesh storage cage, also named as wire butterfly cage, wire basket cage, metal wire logistics container, are a type of popular industrial folding wire container, with sturdy, durable, portable, foldable, collapsible, stackable characters, they are widely used for bulk materials handling, transport and storage, especially for automotive parts, accessories and spare parts, hardware, machinery, electronics etc. 1), Tough, all-welded wire containers provide quick content clearly visible, even when stacked 3 and 4 containers high, making it easy to see what stored inside, this promotes better material flow and more efficient inventory control. 2), Open mesh welded wire construction allows dirt, dust, debris to pass through keeping the contents cleaner. 3), Half drop gate makes it easy to load or unload parts. 4), Foldable design, allowing the sides to collapse, fold flat for space-saving when not in use or return shipment. 5), High strength design permits secure, compact storage, the sturdy wire mesh containers can hold up to max 2000KG with three more fully loaded wire containers stacked on top. 6), These Containers are made with rigid wire after welding, electro-galvanized finished to provide a lifetime of rust resistance.

Features of folding steel mesh storage cage: Inventory levels are visible, making it easy to monitor product levels at a glance Convenient drop side gate design for access to products, even when containers are stacked Four way fork entry, easily moved by forklift, even when fully loaded Sturdy spiral hinges, welded, interlocking channel base, heavy-duty structure Foldable, collapsible, Stackable design, folds flat for easy carry, recycle and storage when not in use Custom sizes and options are available Our common standard type of wire container: Upon to your usage, we have several standard types of wire containers for your choice. If there are not suitable one for you, we also accept your customized design.

Features of folding steel mesh storage cage: Inventory levels are visible, making it easy to monitor product levels at a glance Convenient drop side gate design for access to products, even when containers are stacked Four way fork entry, easily moved by forklift, even when fully loaded Sturdy spiral hinges, welded, interlocking channel base, heavy-duty structure Foldable, collapsible, Stackable design, folds flat for easy carry, recycle and storage when not in use Custom sizes and options are available Our common standard type of wire container: Upon to your usage, we have several standard types of wire containers for your choice. If there are not suitable one for you, we also accept your customized design.

In order to make quotation for you quickly , please tell us the follow information : 1, For our standard items: 1), The item No. you interested. 2), The quantity you plan to purchase. 3), The destination. 2, For your owner design: 1), Please provide AutoCAD drawing (if available). 2), Size of the cage: length, width, height. 3), Mesh pitch:25x50, 50x50, or 50x100 mm. 4), Wire diameter:4.8 to 6.3 mm. 5), Loading capacity of each container. 6), The quantity you plan to purchase. 7), The destination. 8), Others requirements, such as PP hollow sheet, cover, interlayer wire deck, caster, etc. The product information: 1, The Material: High quality No. Q235 steel wire and cold-rolled steel plate. 2, Production Procedure:  3, The structure of wire cage:

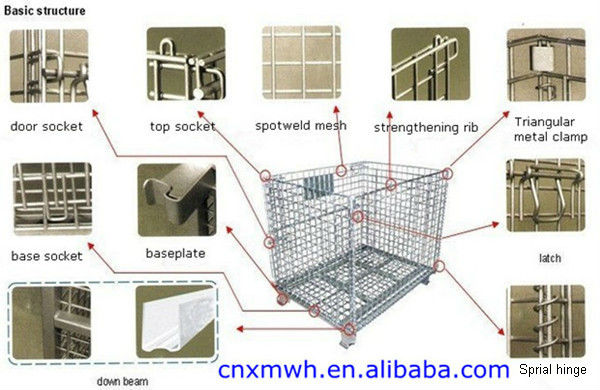

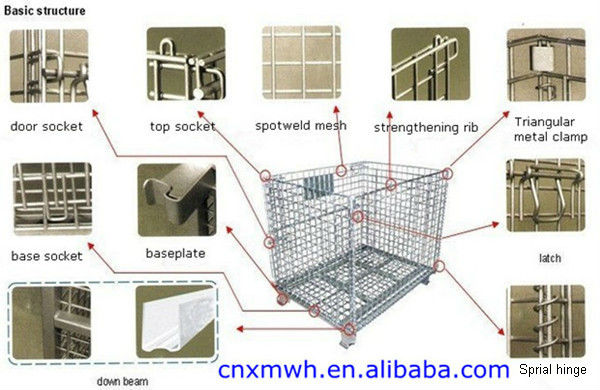

3, The structure of wire cage:

A, Bending-shaped handle latch, open and lock the door naturally. B, U-shaped down beam, reinforce loading capacity. C, Particular structure of baseplate, ensure the stability when stacked. D, Spring hinge connect the reticular wire mesh, foldable when not in use. E, Triangular metal clamp on the top to ensure the intensity of the spring hinge. F, Auxiliary strengthened rib structure, ensure the stability when unfold. G, Multiple spot welding technique, ensure the solidity and durability. H, Independent bolt and drop gate for easy to fetch products when stacked. 4, Method of folding:

A, Bending-shaped handle latch, open and lock the door naturally. B, U-shaped down beam, reinforce loading capacity. C, Particular structure of baseplate, ensure the stability when stacked. D, Spring hinge connect the reticular wire mesh, foldable when not in use. E, Triangular metal clamp on the top to ensure the intensity of the spring hinge. F, Auxiliary strengthened rib structure, ensure the stability when unfold. G, Multiple spot welding technique, ensure the solidity and durability. H, Independent bolt and drop gate for easy to fetch products when stacked. 4, Method of folding:  5, Package: Well package to ensure the steady and safety in transit.

5, Package: Well package to ensure the steady and safety in transit.  6, Usage: Nowaday, the folding steel mesh storage cages play an important role in cargo logistics, and they are widely used for cargo handling, transportation and storage, especially for automotive parts, accessories and spare parts, hardware, machinery, electronics, warehousing etc.

6, Usage: Nowaday, the folding steel mesh storage cages play an important role in cargo logistics, and they are widely used for cargo handling, transportation and storage, especially for automotive parts, accessories and spare parts, hardware, machinery, electronics, warehousing etc.

Any information you want to know from us, please don't hesitate to contact us, we will reply you soon. thank you.

Any information you want to know from us, please don't hesitate to contact us, we will reply you soon. thank you.

1, Mesh cage design.

2, For material handling, transport, storage

3, Foldable, stackable

Brief description of folding steel mesh storage cage Hard working, returnable wire containers deliver high visibility savings. Handle, transport and store bulk parts and material the efficient way. Perfect container for in-line assembly work or work-in-process operations. Fully collapsible and stackable 4 high. Folding steel mesh storage cage, also named as wire butterfly cage, wire basket cage, metal wire logistics container, are a type of popular industrial folding wire container, with sturdy, durable, portable, foldable, collapsible, stackable characters, they are widely used for bulk materials handling, transport and storage, especially for automotive parts, accessories and spare parts, hardware, machinery, electronics etc. 1), Tough, all-welded wire containers provide quick content clearly visible, even when stacked 3 and 4 containers high, making it easy to see what stored inside, this promotes better material flow and more efficient inventory control. 2), Open mesh welded wire construction allows dirt, dust, debris to pass through keeping the contents cleaner. 3), Half drop gate makes it easy to load or unload parts. 4), Foldable design, allowing the sides to collapse, fold flat for space-saving when not in use or return shipment. 5), High strength design permits secure, compact storage, the sturdy wire mesh containers can hold up to max 2000KG with three more fully loaded wire containers stacked on top. 6), These Containers are made with rigid wire after welding, electro-galvanized finished to provide a lifetime of rust resistance.

Features of folding steel mesh storage cage: Inventory levels are visible, making it easy to monitor product levels at a glance Convenient drop side gate design for access to products, even when containers are stacked Four way fork entry, easily moved by forklift, even when fully loaded Sturdy spiral hinges, welded, interlocking channel base, heavy-duty structure Foldable, collapsible, Stackable design, folds flat for easy carry, recycle and storage when not in use Custom sizes and options are available Our common standard type of wire container: Upon to your usage, we have several standard types of wire containers for your choice. If there are not suitable one for you, we also accept your customized design.

Features of folding steel mesh storage cage: Inventory levels are visible, making it easy to monitor product levels at a glance Convenient drop side gate design for access to products, even when containers are stacked Four way fork entry, easily moved by forklift, even when fully loaded Sturdy spiral hinges, welded, interlocking channel base, heavy-duty structure Foldable, collapsible, Stackable design, folds flat for easy carry, recycle and storage when not in use Custom sizes and options are available Our common standard type of wire container: Upon to your usage, we have several standard types of wire containers for your choice. If there are not suitable one for you, we also accept your customized design. | Standard types of wire container | |||||||||

| Item No. | Specification | Wire diameter | Mesh gauge | Load capacity | Weight | Feet height | Surface treatment | ||

| External size (mm) | Internal size (mm) | (mm) | (mm) | (kg) | (kg)±2% | (mm) | |||

| A Series | A1-800 | 800*600*640 | 750*550*500 | 5.8 | 50*50 | 800 | 29 | 100 | Bright or color galvanized |

| A1-700 | 5.6 | 50*50 | 700 | 27.8 | |||||

| A1-600 | 5.3 | 50*50 | 600 | 23 | |||||

| A1-400 | 4.8 | 50*50 | 400 | 20.6 | |||||

| A2-600 | 5.8 | 50*100 | 600 | 25 | |||||

| A3-1000 | 6.3 | 50*50 | 1000 | 32 | |||||

| B Series | B1-1200 | 1000*800*840 | 950*750*700 | 5.8 | 50*50 | 1200 | 44.8 | ||

| B1-1000 | 5.6 | 50*50 | 1000 | 42.8 | |||||

| B1-800 | 5.3 | 50*50 | 800 | 35.2 | |||||

| B1-600 | 4.8 | 50*50 | 600 | 30.8 | |||||

| B2-1000 | 5.8 | 50*100 | 1000 | 39 | |||||

| B3-1500 | 6.3 | 50*50 | 1500 | 51 | |||||

| C Series | C1-1500 | 1200*1000*890 | 1150*950*750 | 5.8 | 50*50 | 1500 | 60.8 | ||

| C1-1300 | 5.6 | 50*50 | 1300 | 55.8 | |||||

| C2-1000 | 5.8 | 50*100 | 1000 | 53.8 | |||||

| C2-800 | 5.6 | 50*100 | 800 | 48.4 | |||||

| C3-2000 | 6.3 | 50*50 | 2000 | 68 | |||||

| Remark: the size, wire diameter, mesh gauge can be customized as your design. | |||||||||

3, The structure of wire cage:

3, The structure of wire cage:

A, Bending-shaped handle latch, open and lock the door naturally. B, U-shaped down beam, reinforce loading capacity. C, Particular structure of baseplate, ensure the stability when stacked. D, Spring hinge connect the reticular wire mesh, foldable when not in use. E, Triangular metal clamp on the top to ensure the intensity of the spring hinge. F, Auxiliary strengthened rib structure, ensure the stability when unfold. G, Multiple spot welding technique, ensure the solidity and durability. H, Independent bolt and drop gate for easy to fetch products when stacked. 4, Method of folding:

A, Bending-shaped handle latch, open and lock the door naturally. B, U-shaped down beam, reinforce loading capacity. C, Particular structure of baseplate, ensure the stability when stacked. D, Spring hinge connect the reticular wire mesh, foldable when not in use. E, Triangular metal clamp on the top to ensure the intensity of the spring hinge. F, Auxiliary strengthened rib structure, ensure the stability when unfold. G, Multiple spot welding technique, ensure the solidity and durability. H, Independent bolt and drop gate for easy to fetch products when stacked. 4, Method of folding:  5, Package: Well package to ensure the steady and safety in transit.

5, Package: Well package to ensure the steady and safety in transit.  6, Usage: Nowaday, the folding steel mesh storage cages play an important role in cargo logistics, and they are widely used for cargo handling, transportation and storage, especially for automotive parts, accessories and spare parts, hardware, machinery, electronics, warehousing etc.

6, Usage: Nowaday, the folding steel mesh storage cages play an important role in cargo logistics, and they are widely used for cargo handling, transportation and storage, especially for automotive parts, accessories and spare parts, hardware, machinery, electronics, warehousing etc.

Any information you want to know from us, please don't hesitate to contact us, we will reply you soon. thank you.

Any information you want to know from us, please don't hesitate to contact us, we will reply you soon. thank you. Send your inquiry to this supplier

Send Inquiry