1 / 5

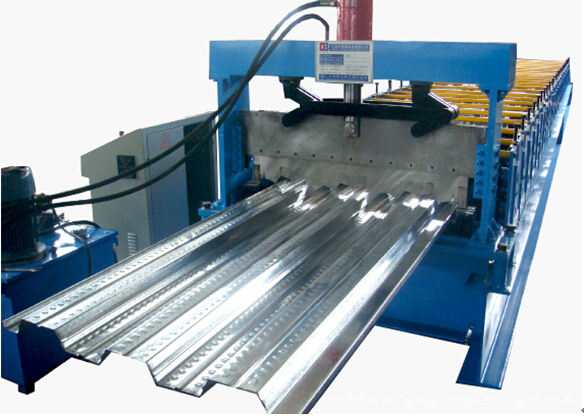

Floor Deck Sheet Cold Roll Forming Machine

| Model No. : | ZT-004-12 |

|---|---|

| Brand Name : | zhongtuo |

| Material : | Ceramic Tiles |

Cangzhou, Hebei, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Video

Product description

Floor Deck Sheet Cold Roll Forming Machine

Product description

New building bearing plate roll forming machine by this machine is used for building surface panels, it has many

advantages, such as high wave, high strength, high automation and low cost. Steel structural floor panel is the type of

steel construction material with character of low light, hard, easy to install, which extensively apply in constructing

skyscraper, residential building and bridge. HBYX series steel structural floor panel with the feature of reliable,

convenient operation, automatic can be used in various steel structural floor panels forming. This machine is composed

of uncoiler, feed leading table, main forming machine, punching system, cutting device, hydraulic station and computer

control system.

This is the new type we engineer for floor deck roll forming machine, if it can meet your need, please contact us.

The characteristics of floor deck plate roll forming machine products

1, quick to adapt to the steel structure construction requirements, can provide solid work platform in a short period of

time, and can use multiple floor deck laid pressed steel plate, plate layer hierarchical pouring of concrete slab

construction.

2, in the use of phase floor deck steel plate as a concrete floor, also can increase the stiffness of the floor, to save the

consumption of steel and concrete.

3, contour plate surface embossing make floor deck maximum binding force between plate and concrete, to form the

whole, with stiffener, make floor deck plate system has a high bearing capacity.

4, under the condition of the cantilever, floor deck plate only as a permanent template. The length of the cantilever can

be set according to the properties of cross section floor deck board. In order to prevent the cantilever plate cracking,

needs in the bearing place in accordance with the structural engineers design with negative reinforcement.

Drawings profile or finished product pictures

building bearing plate roll forming machine Specification of Metal Floor Deck Sheet Panel Roll Forming Machine

|

Main parameters of ZT 915 floor deck forming machine |

||

|

1 |

Suitable material |

galvanizes sheet/ colored coil |

|

2 |

Width of the feeding material |

1300 mm |

|

3 |

Effective width of the plate |

915 mm |

|

4 |

Thickness of feeding material |

0.8-1.2mm |

|

5 |

Productivity |

15m/min |

|

6 |

Two Main motor power |

11kw +11kw |

|

7 |

Rollers' material |

45# steel Rolling chromium |

|

8 |

Diameter of shaft |

90mm |

|

9 |

Wall thickness of the main forming machine |

22mm steel plate |

|

10 |

Backboard Thickness |

20mm |

|

11 |

Cutting hydraulic system`s motor power |

5.5kw |

|

12 |

control system, |

PLC |

|

13 |

Dimensions of major structure |

13000mm*1400mm*1600mm |

|

14 |

Weight |

14T |

|

15 |

Stations |

27 |

Production process of Metal Floor Deck Sheet Panel Roll Forming Machine

Uncoiling→Feeding material into machine→Roll forming→Measuring length→Step formed→ Auto cutting→Products receiving

building bearing plate roll forming machine Un-coiler System of Metal Floor Deck Sheet Panel Roll Forming Machine

Usage: It is used to support the steel coil and uncoil it in a turntable way..Passive uncoil pulled by roll forming system

Loading-capacity:5TUncoiling-width:1000/1200/1250mm

Inner-diameter: 450-550mm

Entry Beach

Usage:Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate panel.

Main Roll forming machine

Usage :In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission, roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Frame : 350 H steel

Drive mode: chain

Material of rollers:45# steel, surface hard chromium plating.

Length of the main part:14200*1300*1400mm

Voltage:380V/50HZ3Phase

Roller fixer : middle plate

Material of shafts: 45#steel

Diameter of shafts: φ80mm

Number of rollers : 30 rollers

Shearing Mechanism

Usage :It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Feature : Ensure stability, precision and cutting speed

Function: Automatic cutting controlled by PLC.

Material of blades: Cr12 quenched

Power supply : hydraulic power

machine pictures for your reference:

Cangzhou, Hebei, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Video

Send your inquiry to this supplier