1 / 1

Floatation Separation Copper Machine

| Model No. : | SF-0.37 |

|---|---|

| Brand Name : | Shanghai Minggong |

Product description

Product Description 1.Description of flotation machine: Flotation machine can be used to separate non-ferrous metal, ferrous metal, noble metal, non-metallic mine, chemical material. It can be used in roughing, scavenging, selection or reverse flotation. In the flotation process, after being mixed with drug, some qualified mineral attaches on bubble, floats on the surface of slurry and is scraped out, other mineral still stays in the slurry, so the separating purpose is finished.

2.Principle of flotation machine : flotation machine is applicable for the separation of nonferrous metal and ferrous metal. It is also used for separating nonmetal, such as fluorite and talcum.Through V belt transmission, which brings centrifugal effect to form the negative pressure. On the one hand, the flotation machine inhales sufficient air to mix with ore slurry; On the other hand it stirs ore slurry and mix with medication to form the mineralized froth. By adjusting the height of flashboard to control the liquid level and make the useful froth scraped by loam board.

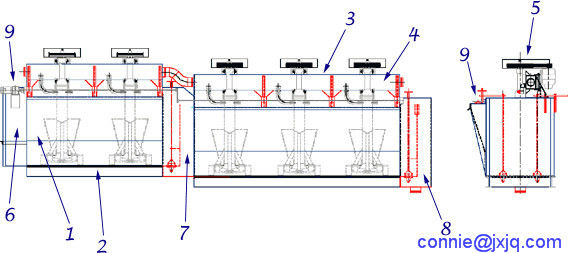

1.Heavy Duty Flotation Tank Construction 2.Removable Flotation Machine Wear Liners 3.Flotation Machine Superstructure 4.Flotation Machine Mechanism

5.Flotation Machine V-Belt Drive 6.Flotation Machine Feed Box

7.Flotation Machine Transition Box 8.Flotation Machine Discharge Box 9.Flotation Machine Froth Paddle Assembly (optional)

3.Technical Parameters of Flotation Machine : SF Series Flotation Machine:

Model | Volume | Size of tank (L×W×H) (mm) | Impeller Dia.(mm) | Impeller speed(r/min) | Capacity | Motor power(kw) | Air flow sucked

| Weight of singe tank(kg) |

SF-0.15 | 0.15 | 500×500×600 | 200 | 536 | 0.06-0.18 | 1.5/0.55 | 0.8-1 | 269 |

SF-0.37 | 0.37 | 700×700×750 | 296 | 386 | 0.2-0.4 | 1.5/0.55 | 0.8-1 | 468 |

SF-0.7 | 0.7 | 820×900×950 | 350 | 400 | 0.3-0.9 | 3/1.1 | 0.8-1 | 805 |

SF-1.2 | 1.2 | 1100×1100×1100 | 450 | 312 | 0.6-1.2 | 5.5/1.1 | 1-1.2 | 1373 |

SF-2.8 | 2.8 | 1700×1600×1150 | 550 | 268 | 1.5-3.5 | 11/1.5 | 1-1.2 | 2138 |

SF-4 | 4 | 1850×2050×1200 | 650 | 220 | 2--4 | 15/1.5 | 1-1.2 | 2582 |

SF-8 | 8 | 2200×2900×1400 | 760 | 191 | 4--8 | 30/1.5 | 0.9-1 | 4129 |

SF-10 | 10 | 2200×2900×1700 | 760 | 191 | 5--10 | 30/1.5 | 0.9-1 | 4486 |

SF-16 | 16 | 2850×3800×1700 | 760 | 191 | 5--16 | 30×2/1.5 | 0.9-1 | 8320 |

SF-20 | 20 | 2850×3800×2000 | 760 | 191 | 5--20 | 30×2/1.5 | 0.9-1 | 9828 |

| Model | XJK-0.35(3A) | XJK-0.62(4A) | XJK-1.1(5A) | XJK-2.8(6A) | XJK-5.8(7A) | ||

Effective Volume(m3) | 0.35 | 0.62 | 1.1 | 2.8 | 5.8 | ||

Capacity(m3/min) | 0.18~0.4 | 0.3~0.9 | 0.6~1.6 | 1.5~3.5 | 3~7 | ||

Rotate Speed(r/min) | 470 | 400 | 330 | 280 | 240 | ||

Impeller Dia (mm) | 300 | 350 | 500 | 600 | 750 | ||

Motor | Model | Rotator | Y90L-4 | Y100L2-4 | Y132M2-6 | Y160L-6 | Y200L2-6(Y225M-6) |

Scraper | Y90S-4 | Y90S-4 | Y90S-4 | Y90S-4 | Y90L-4 | ||

Power(Kw) | Impeller Motor | 1.5 | 3 | 5.5 | 11 | 22(30) | |

Scraper Motor | 1.1 | 1.1 | 1.1 | 1.1 | 1.5 | ||

Weight:(t/Single Tank) | 0.43 | 0.86 | 1.38 | 2.33 | 3.533 | ||

| Model | Size of tank (mm) | Single effective volume(kg) | Effective volume(m³) | Capacity (m³/min) | Motor of main shaft | Impeller | Motor of scraper | Wind pressure of blower (kpa) |

| Power(kw) | Dia.(mm) | Power(kw) | ||||||

| KYF-1 | 1000×1000×1100 | 826.31 | 1 | 0.2-1 | 4 | 340 | 1.1 | ≥12.6 |

| KYF-2 | 1300×1300×1250 | 1419 | 2 | 0.4-2 | 5.5 | 410 | 1.1 | ≥14.7 |

| KYF-3 | 1600×1600×1400 | 1885 | 3 | 0.6-3 | 7.5 | 480 | 1.5 | ≥19.8 |

| KYF-4 | 1800×1800×1500 | 2206 | 4 | 1.2-4 | 11 | 550 | 1.5 | ≥19.8 |

| KYF-8 | 2200×2200×1950 | 3600 | 8 | 3-8 | 15 | 630 | 1.5 | ≥21.6 |

| KYF-16 | 2800×2800×2400 | 5900 | 16 | 4-16 | 30 | 740 | 1.5 | ≥25.5 |

| KYF-24 | 3100×3100×2900 | 7500 | 24 | 4-24 | 30 | 800 | 1.5 | ≥30.4 |

| KYF-38 | 3600×360×3400 | 10300 | 38 | 10-38 | 37 | 880 | 1.5 | ≥34.3 |

| The parameters are appr oximate and the actual capacity depends on the material and conditions. For more information please contact Shanghai Minggong. | ||||||||

Packaging & Shipping Packing : standard container,spare parts will be packed in wooden cases or as per customer requirement FAQ We’d like to recommend a suitable production line for you and send you our best quotation, could you please provide us some more information about your requirement as follows: ♥ What is the raw ore and particle size of it pls?If possible,pls kindly provide us the chemical analysis report. ♥ What is the raw ore grade and your required finished ore grade pls?

Packaging & Shipping Packing : standard container,spare parts will be packed in wooden cases or as per customer requirement FAQ We’d like to recommend a suitable production line for you and send you our best quotation, could you please provide us some more information about your requirement as follows: ♥ What is the raw ore and particle size of it pls?If possible,pls kindly provide us the chemical analysis report. ♥ What is the raw ore grade and your required finished ore grade pls? ♥ What is your required capacity( t/h) pls? ♥ Do you have any other requirement pls? Company Information Shanghai Minggong Heavy Equipment CO., LTD is one high-tech enterprise, which involves R&D, production, sales and service as well. In the past 20 years, we devote to producing mining equipments, sand making machines and industrial grinding mills, offering expressway, rail way and water conservancy projects the solution of making high grade sand and matched equipments.

| The head office of Shanghai Minggong is in Shanghai- the international financial centre. Here we have modern production base of Eighteen thousands square meters, professional R&D institution and technology team, which make us world-class company. Here all Minggong machines are designed produced, assembled and texted according to the ISO9001:2008. Till now, our products are sold to 130 countries, being the popular equipments in global crushing and grinding industry. With the development of our Shanghai Minggong , we would like to help more and more customers start their business in mining and construction industries, offer them the best solution, much more advanced machinery and better service. |

Characteristics

Characteristics  Impact crusher is also called impact breaker which is widely used in rock mining and quarrying and stone crushing. It is often seen in quarrying plant, ore beneficiation plant and power station and it is a important impact crushing machine. During the rock mining process, the impact crusher is suitable for medium and fine crushing the rocks. After the materials are sent into the material feeding mouth through the feeding machine, they meet the impeller rotating with high speed, and impact to the impacting plate with high speed and are crushed. As a result, it can also be called mineral impact crusher or impact stone breaker.The application of coal impact crusher in power plant: In the thermal power plant, the coal is often raw materials.

Impact crusher is also called impact breaker which is widely used in rock mining and quarrying and stone crushing. It is often seen in quarrying plant, ore beneficiation plant and power station and it is a important impact crushing machine. During the rock mining process, the impact crusher is suitable for medium and fine crushing the rocks. After the materials are sent into the material feeding mouth through the feeding machine, they meet the impeller rotating with high speed, and impact to the impacting plate with high speed and are crushed. As a result, it can also be called mineral impact crusher or impact stone breaker.The application of coal impact crusher in power plant: In the thermal power plant, the coal is often raw materials.  Scope of product

Scope of product  Factory

Factory

Weldment: The process technics of connecting the two machined workpieces atoms by use of either or both of heating,pressure. Technical Exchange:Effective exchange at the machining site with presence of relevant technicians and workers improves the workpieces machining coordination, and utility and safety as well.

Weldment: The process technics of connecting the two machined workpieces atoms by use of either or both of heating,pressure. Technical Exchange:Effective exchange at the machining site with presence of relevant technicians and workers improves the workpieces machining coordination, and utility and safety as well.Metal workpieces Machining:Machining metal workpieces to meet relevant process requirements by use of the lathes.Rolling: Rolling machine rolls metal workpieces constantly to reach the required radians.Ground Level Lathe: Machining Mainly the workpieces with the diameter between 800mm and 4000mm,and length within 13m,such as ring plates,flanges,shell covers, valves etc.

Sand Blasting:Clean and de-rust the large workpieces surface and integrate outer surface,which strengthens adhesion between the outer workpiece surface and coating.

LAB 1: Chemical ores tests and Analyzing Report Room

LAB 2:Ores Measuring and Analyzing Operation Room

Radiography Room:Using flaw detector to detect if there is any crack or other defects inside steel plates or other workpieces.

Oxygen Cutting Equipment: Using oxygen cutting to shape the steel workpieces into the suitable one and size. Comprehensive

Send your inquiry to this supplier