1 / 1

Fibreglass / Filter Mat / Filter Cloth Laser Cutter

| Model No. : | CJG-250400LD |

|---|---|

| Brand Name : | Golden Laser |

| Machine Type : | Laser Cutting Machine |

Product description

Fibreglass / Filter Mat / Filter Cloth Laser Cutter

Compared with the traditional manual cutting or electric scissors, laser cutting adopts CNC control, not only cutting accuracy, more efficient, but also greatly saving the material and labor costs. In addition to cutting, laser can also achieve precise trimming for rolls of filtering material, enhancing filter's actual effect, this is can't be done by other cutting ways, and filtering material manufacturer urgently needs to solve the problem.

At the same time, laser can also do punching for filter material with various specifications and graphics so as to create more efficient and practical solutions for wastewater treatment, chemical industry of filtering crystallization.

As an emerging technology and alternative technology, laser technology, the deepening of the application with unique a number of advantages, will inject more vigor and vitality of hope to the development of filtration industry.

Filter Industry Laser Cutting Solutions

Non-woven and special fabric is very suitable for laser cutting. In order to cater to the special requirements of filter industry for material cutting edge, GOLDEN LASER provides a variety of laser power for matching, and provides users with a complete laser cutting solution.

Laser cutting systems for filters, filter cloth, filter materials, filter mats

Filter cloth comfortably cut to any size

› Automatic sealing of cutting edges. No fraying of the cloth

› No tool wear – no loss of quality

› High precision and accuracy of repeatability

› Automated production process with conveyor and feeding systems

› Automatic switching of marking system and laser head emitting beam. Perforation, marking and cutting all in one step.

› Simple production via a PC design program

› Compatible with a variety of graphics format, can be completed any shape of cutting.

› Filter cloth cutting edges can be customized, cloth edges lifetime can be set as required.

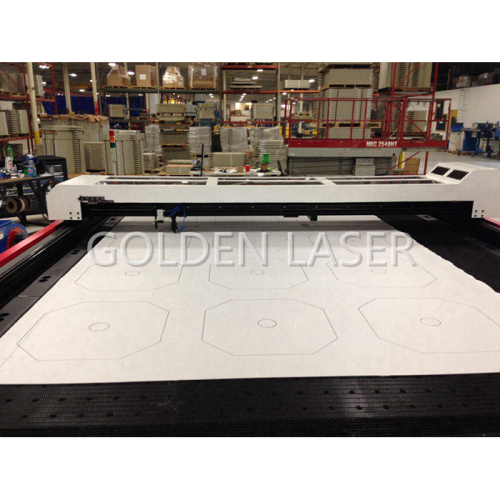

› Vacuum adsorption working table, prevention of cloth edges crimping or warping.

› Complete exhaust and filtering of cutting emissions possible

› Fully enclosed structure (optional) to ensure the cutting dust does not leak, suitable for operation in the intensive production plant.

Filter material dust-free cutting by laser

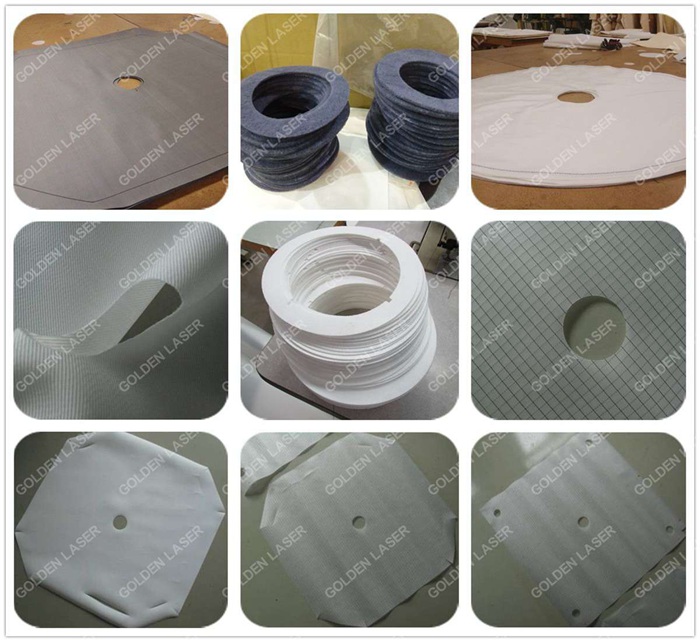

Precisely cut almost Any Kinds of material in Any Shape

Typical filter media are: Fiberglass Cloth, Polyethylene (PE), Polypropylene (PP), Polyester (PES), Polyamide (PA), Fibre glass, Non-woven, Fabric, Paper, Felt, PTFE, etc.

Filter Cloth Laser Cutting Machine

Marker Pen

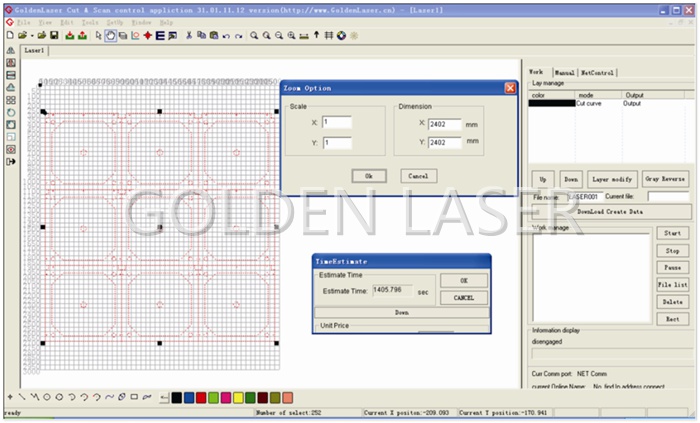

User-friendly Software Interface

Main Configuration

• Working Table Size:

1600mm X 3000mm (63" X 118.1")

2100mm X 3000mm (82.6" X 118.1")

2500mm X 3000mm (98.4" X 118.1")

2500mm X 4000mm (98.4" X 157.5")

• Laser Type:

CO2 RF metal laser tube (150W / 275W / 400W)

CO2 DC glass laser tube (80W / 130W / 150W)

• Conveyor working table for continuous cutting

Conveyor working table is used for textile machining and is particularly suitable for thin and flexible materials.

With auto-feeding device (optional) realizes high-speed continuous cutting on fabrics.

By using this automatic material feeder, filter material can be fed for laser cutting directly from the roll.

• Servo motor control system

• Software, supporting AI, BMP, DXF, DST, etc.

User-friendly interface. Easy to use. All for the best user experience.

• 2 sets 3000W exhaust fan, 1 set 550W exhaust fan, Air blower

• Constant temperature water chiller

• 5`` LCD display panel

• AC220V / 50-60Hz/ single phase

Optional Configuration

• Auto-feeding system

The auto-feeder realizes continuous cutting fabric.

• Mark pen

The compressed air controlled marking system to apply ink markings to the material.

Marking by cutting at the same time, guarantee the production efficiency.

• Auto-recognition system

• Auto nesting software

• Multi-laser head

Filter Cloth Laser Cutting Samples

Send your inquiry to this supplier