1 / 6

Factory price Eco-friendly CE quality Waste Tyre to oil Pyrolysis Plant

Get Latest Price

Send Inquiry

| Model No. : | LN--2200*6000 |

|---|---|

| Brand Name : | Lanning |

Ningling Lanning Technology Co., Ltd.

You might also like

Product description

Product Description Features and Advantages 1) Q245R steel, auto-welding 2) 42-45% oil yield for tire,60%-70% for plastic 3) carbon black auto-discharging 4) waste gas recycle system, energy-saving 5) Eco-friendly design 6) auto-alarm and safety valve devices 7) catalyst formula provided 8) free installation 9) 6 years life for the host reactor 10) new condition,factory direct sale Available Raw Materials and Oil Output

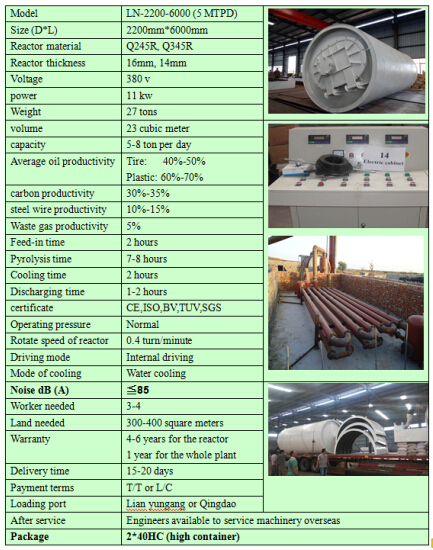

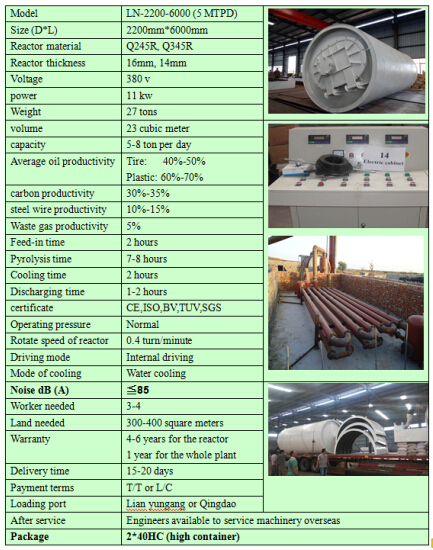

Technical Parameters  Product Overviews

Product Overviews

The Final Products  Production Flow 1. Put the waste tyre, plastic or rubber into the reactor, catalysis and pyrolysis the tyer. 2. Then output the oil gas, the oil gas will go through the condenser and be liquefied to oil. 3. After finishing the process, the carbon black will be discharged from the specialized carbon black door. 4. Some part of the oil gas which cannot be liquefied will be burned as fuel to heat the reactor directly through the waste gas burning system. Between the oil tank and the heating furnace there wil be the water sealing tank to work as anti-fire system. And the waste smoke will be processed by desulfurization system firstly and then discharged into the air.

Production Flow 1. Put the waste tyre, plastic or rubber into the reactor, catalysis and pyrolysis the tyer. 2. Then output the oil gas, the oil gas will go through the condenser and be liquefied to oil. 3. After finishing the process, the carbon black will be discharged from the specialized carbon black door. 4. Some part of the oil gas which cannot be liquefied will be burned as fuel to heat the reactor directly through the waste gas burning system. Between the oil tank and the heating furnace there wil be the water sealing tank to work as anti-fire system. And the waste smoke will be processed by desulfurization system firstly and then discharged into the air.  Packaging & Shipping We will punctually pack and deliver the products to you withen 20 days after receiving 30% deposit.

Packaging & Shipping We will punctually pack and deliver the products to you withen 20 days after receiving 30% deposit.  The Workshop We have standard workshop, professional engineers and advanced equipment.

The Workshop We have standard workshop, professional engineers and advanced equipment.  Company Information Ningling Lanning Technology Co., LTD is a company has been specialized in manufacturing waste tyre or plastic recycling machine for about ten years. Now, our products are very popular both at home and abroad because of the perfect after-sale service and high quality.

Company Information Ningling Lanning Technology Co., LTD is a company has been specialized in manufacturing waste tyre or plastic recycling machine for about ten years. Now, our products are very popular both at home and abroad because of the perfect after-sale service and high quality.

After-Sales Service a. Installation, commissioning and training Our company would send installation technician to the buyer for the installation, commissioning and training. b. Catalyst formula Our company would provide the formula of catalyst free of charge. c. Warranty period One year warranty, lifelong time maintenance.

After-Sales Service a. Installation, commissioning and training Our company would send installation technician to the buyer for the installation, commissioning and training. b. Catalyst formula Our company would provide the formula of catalyst free of charge. c. Warranty period One year warranty, lifelong time maintenance.

Item | Raw Materials | Oil Output |

Waste Tyres | Steel Tyres | 40%-45% |

Nylon Tyres | 40% | |

Bike Tyres | 35% | |

Waste Plastcis | Plastics bags (shopping) | 50% |

Weaves or handbags | 60% | |

Cable Skin | PE Cable Skin | 35% |

PVC Cable Skin | 25% | |

Pure Rubber Cable Skin | 35% | |

Telephone Line | 50% | |

Waste Paper Mixture from Paper Factory | Rough Material | 15% |

Washed Material | 20-25% | |

PE Material | 70% | |

Shoes Soles | Sports Shoes Soles | 25-33% |

Black Rubber Soles | 35% | |

Gum Rubber Soles | 45% | |

Others | Common Rubber Tubes | 30% |

Carpets | 35% | |

Aluminum Foil Paper | 30% | |

Car Glass Layering | 50% | |

PP Beverage Bottle | 50% |

Product Overviews

Product Overviews

| water sealing |

oil tank |

|

damper tanks |

cooling tower |

electricity cabinet |

Production Flow 1. Put the waste tyre, plastic or rubber into the reactor, catalysis and pyrolysis the tyer. 2. Then output the oil gas, the oil gas will go through the condenser and be liquefied to oil. 3. After finishing the process, the carbon black will be discharged from the specialized carbon black door. 4. Some part of the oil gas which cannot be liquefied will be burned as fuel to heat the reactor directly through the waste gas burning system. Between the oil tank and the heating furnace there wil be the water sealing tank to work as anti-fire system. And the waste smoke will be processed by desulfurization system firstly and then discharged into the air.

Production Flow 1. Put the waste tyre, plastic or rubber into the reactor, catalysis and pyrolysis the tyer. 2. Then output the oil gas, the oil gas will go through the condenser and be liquefied to oil. 3. After finishing the process, the carbon black will be discharged from the specialized carbon black door. 4. Some part of the oil gas which cannot be liquefied will be burned as fuel to heat the reactor directly through the waste gas burning system. Between the oil tank and the heating furnace there wil be the water sealing tank to work as anti-fire system. And the waste smoke will be processed by desulfurization system firstly and then discharged into the air.  Packaging & Shipping We will punctually pack and deliver the products to you withen 20 days after receiving 30% deposit.

Packaging & Shipping We will punctually pack and deliver the products to you withen 20 days after receiving 30% deposit.  The Workshop We have standard workshop, professional engineers and advanced equipment.

The Workshop We have standard workshop, professional engineers and advanced equipment.  Company Information Ningling Lanning Technology Co., LTD is a company has been specialized in manufacturing waste tyre or plastic recycling machine for about ten years. Now, our products are very popular both at home and abroad because of the perfect after-sale service and high quality.

Company Information Ningling Lanning Technology Co., LTD is a company has been specialized in manufacturing waste tyre or plastic recycling machine for about ten years. Now, our products are very popular both at home and abroad because of the perfect after-sale service and high quality.

After-Sales Service a. Installation, commissioning and training Our company would send installation technician to the buyer for the installation, commissioning and training. b. Catalyst formula Our company would provide the formula of catalyst free of charge. c. Warranty period One year warranty, lifelong time maintenance.

After-Sales Service a. Installation, commissioning and training Our company would send installation technician to the buyer for the installation, commissioning and training. b. Catalyst formula Our company would provide the formula of catalyst free of charge. c. Warranty period One year warranty, lifelong time maintenance. Send your inquiry to this supplier

Send Inquiry

reactor cover

reactor cover