1 / 3

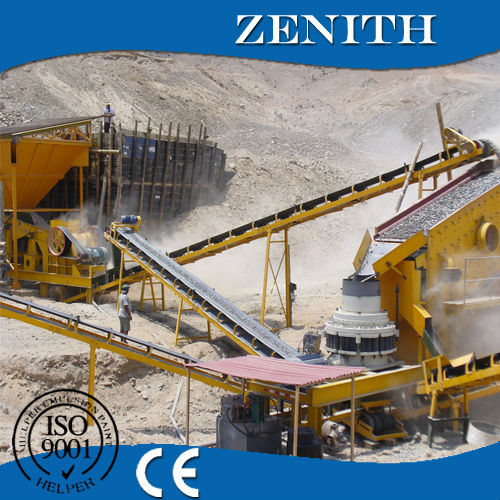

Excellent quality Copper Ore Beneficiation Plant

Get Latest Price

Send Inquiry

| Model No. : | Stationary Crushing Line in Kenya |

|---|---|

| Brand Name : | Zenith |

Shanghai Zenith Mining And Construction Machinery Co., Ltd.

You might also like

Product description

Product Description Copper Ore Beneficiation Plant Copper ore Beneficiation plant is mainly divided into three parts: crushing part, grinding part and flotation part. 1.Crushing: crushing process is the first and primary process in the copper ore beneficiation plant. Its purpose is crushed copper ore to an appropriate size to suitable for the grinding part . 2.Grinding: grinding is the second step in the copper ore beneficiation plant. It further processing copper ore into smaller size for flotation separation . 3.Flotation: flotation process is the important process . Chemicals are added to the mixer or blender , the chemical reaction . Copper ore first by the jaw crusher to initial broken. Jaw crusher is the coarse crushing machine used in cooper ore primary crushing process. Jaw crusher is principally used to crush forms of mining stones primarily, and the largest compression resistance of the material is 320 MPa. After crushing to a reasonable degree of fineness via elevator, feeder evenly into the ball mill, then grind by the ball mill. Copper Ore Beneficiation Plant For Sale Ore fine after grinding will expected to enter the next process: classification. Spiral classifier with principle of that different proportion of solid particles in the liquid precipitation different speeds, to wash the mixture of ore, grading. After washing and grading of mineral mix when passing magnetic separator,because of the susceptibility of various minerals is different , through magnetic and mechanical forces to separated the magnetic material from the mixture. After initial separation of mineral particles in the separator is fed to the flotation machine, according to the different characteristics put into different drugs minerals, making the minerals to be separated with other substances. After the minerals to be separated, because they contain large amounts of water,so they must be initially concentrated by the concentrator, and then dried by the dryer, and dried to obtain minerals. Finally, copper concentrate grade of 45%. Production Line

Product Description Copper Ore Beneficiation Plant Copper ore Beneficiation plant is mainly divided into three parts: crushing part, grinding part and flotation part. 1.Crushing: crushing process is the first and primary process in the copper ore beneficiation plant. Its purpose is crushed copper ore to an appropriate size to suitable for the grinding part . 2.Grinding: grinding is the second step in the copper ore beneficiation plant. It further processing copper ore into smaller size for flotation separation . 3.Flotation: flotation process is the important process . Chemicals are added to the mixer or blender , the chemical reaction . Copper ore first by the jaw crusher to initial broken. Jaw crusher is the coarse crushing machine used in cooper ore primary crushing process. Jaw crusher is principally used to crush forms of mining stones primarily, and the largest compression resistance of the material is 320 MPa. After crushing to a reasonable degree of fineness via elevator, feeder evenly into the ball mill, then grind by the ball mill. Copper Ore Beneficiation Plant For Sale Ore fine after grinding will expected to enter the next process: classification. Spiral classifier with principle of that different proportion of solid particles in the liquid precipitation different speeds, to wash the mixture of ore, grading. After washing and grading of mineral mix when passing magnetic separator,because of the susceptibility of various minerals is different , through magnetic and mechanical forces to separated the magnetic material from the mixture. After initial separation of mineral particles in the separator is fed to the flotation machine, according to the different characteristics put into different drugs minerals, making the minerals to be separated with other substances. After the minerals to be separated, because they contain large amounts of water,so they must be initially concentrated by the concentrator, and then dried by the dryer, and dried to obtain minerals. Finally, copper concentrate grade of 45%. Production Line

FAQ We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away. If you are new for this business: Many thanks for your trust; we can provide you with design scheme for complete production lines, spot inspection and operator training according to your demands and the conditions of applied spot, we can help you choose the right equipments. We’d like to recommend a suitable model for you and send you a best quotation. So please give us some more information about your requirement in your enquiry. 1.what is the raw material do you want to process? 2.what is the capacity per hour do you need? 3.what is the raw material input size? 4.what is the output size of your product?

FAQ We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away. If you are new for this business: Many thanks for your trust; we can provide you with design scheme for complete production lines, spot inspection and operator training according to your demands and the conditions of applied spot, we can help you choose the right equipments. We’d like to recommend a suitable model for you and send you a best quotation. So please give us some more information about your requirement in your enquiry. 1.what is the raw material do you want to process? 2.what is the capacity per hour do you need? 3.what is the raw material input size? 4.what is the output size of your product? Look forward to your inquiries! ...

Send your inquiry to this supplier

Send Inquiry