1 / 4

EPS Sandwich Wall Panel Production Machine Line

$20000.00

~ $20000.00

/ Set/Sets

Send Inquiry

| Model No. : | EPS Sandwich Wall Panel Production Machine Line |

|---|---|

| Brand Name : | JCX |

| Warranty : | 1 Year |

More

6yrs

Cangzhou, Hebei, China

- Distributor/Wholesaler

- Manufacturer

- Retailer

- Service

- OEM service

- Platform Certification

- Online Expo

- Video

Botou Golden Integrity Roll Forming Machine Co.,Ltd

You might also like

Product description

Brief Introduction

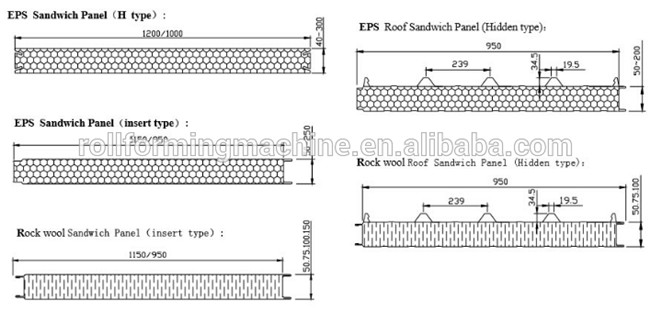

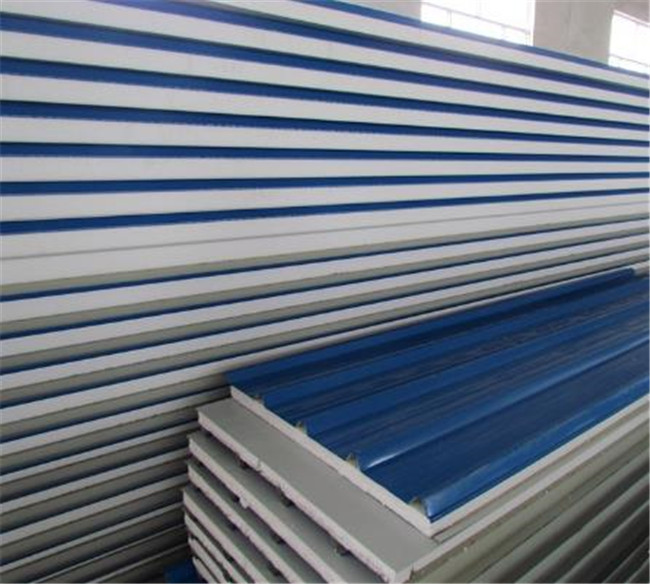

Sandwich panel production line is used for the special purpose of producing the new type constructional material (Sandwich panel), with the function of compounding EPS or Rock wool board to the color steel sheets.

Sandwich panel is very light weight. (1/40 to 1/10 of common brick).It is high strength, warm conservation, water proof, convenient for construction, short construction period etc.

As the ideal constructional material, they can be used to build warehouses, workshops, wide range roofing, air-conditioned houses and so on.

Parameters

| No. | Item | Description |

| 1 | Measurements: | 25,000×3,520×2,800 mm |

| 2 | Weight: | 13 T |

| 3 | Control System: | OMRON Coding System |

| 4 | Main Engine: | Cycloid Pinwheel Reducer |

| 5 | Production Speed: | 0-3.5m / min |

| 6 | Types of Finished Products: | EPS flat board; EPS matchboard;980 matchboard |

| 7 | Voltage: | 380V,50HZ,3Phase |

| 8 | Component Parts: | Uncoiler + roll forming machine + compounding machine + cutting machine + delivery rack |

| 9 | Cutting Methods: | Hydraulic cutting (milling cutter/click-die cutter) |

| 10 | Roller's Material: | Made of #45 steel, chrome plated |

| 11 | Overall Power: | 28kw |

| 12 | Synchronous controller: | KMD04B Synchronous controller |

| 13 | Motor for roll forming machine | Double polar cycloid reducer |

| 14 | Number of Electrical Motor: | 26 |

| 15 | Number of Heating Pipe: | 6.2 kw per pipe |

| 16 | Packing Way: | Anti rust |

| 17 | Products Application: | Roofing, Walling |

Working Flow & Layout:

Control system: NC-PLC auto non-stop rail cutting system

Power supply: 380V, 3-phase, 50-60HzTotal power: 32kw

Working speed: 0-4m/min

Size: 35m× 3m× 2.5m

Weight: 23T

Product thick: 40-250mm

Raw material thick: 0.27-0.8mm

Raw material: (under side) color steel, pvc, aluminized paper

Output: 600, 000m2 per year.

Final Products:

6yrs

Cangzhou, Hebei, China

- Distributor/Wholesaler

- Manufacturer

- Retailer

- Service

- OEM service

- Platform Certification

- Online Expo

- Video

Send your inquiry to this supplier

Send Inquiry