1 / 5

Asphalt Plant With Diesel Oil Burner

| Model No. : | LB 1000 |

|---|---|

| Brand Name : | Others |

| Type : | Asphalt Mixing Plant |

Harbin, Heilongjiang, China

- Manufacturer

- Trade Company

- Platform Certification

- SGS Certification

- Online Expo

Product description

Asphalt Plant With Diesel Oil Burner

Product Description

Asphalt batching plant makes hot mix asphalt in batches. Asphalt plant process are mix of several mechanical.This equipment can be mobile or stationary. Other types of plant that are available in the market today. It is drum mix plant and counter flow plants. But in general the major categories are batch plant and continuous plants.

Asphalt batch plant process involves drying of aggregates and separating. Each aggregate in different compartments and then mixing them in a twin shaft mixer. With bitumen and filler material. In the drum mix plant. The aggregates are heated and mixed with the bitumen and filler material in a continuous process. Both the process however help in making hot mix asphalt. The difference lies in the process.

Advantages

1.Modular integrated design like combining filler elevator and hot mix elevator with mixing tower, convenient to install and dismantle, reduce installation time and cost;

2.No heavy concrete foundation required, compact soil is enough;

3.Rock wool liner for drum dryer effectively reduces heat loss, and specially designed flights greatly improve heat exchange inside the drum;

4.Wear resistant liner for twin shaft mixer extends the service life accordingly;

5.Containerized mixing tower structure, low dust and heat loss;

6.Brand motors, reducers and burners, high efficient and energy saving;

7.TOLEDO weighing sensor, accurate weighing technology;

8.Advanced control system to realize real-time monitor and data transfer between asphalt plant and computer.

Technical Parameters of Environment Asphalt Plant

1. Cold Aggregate Supply System: 5*8 m3 storage bins

2. Drum dryer: Φ1800*8000mm

3. Fuel consumption: oil, 200-1000kg/h; coal, 2500kg/h

4. Dust Collection System: cyclone dust collector/volute casing collector + baghouse dust collector

5. Filler Supply System: 24t/h (optional filler tank)

6. Bitumen Supplying System: 2*40m3 bitumen tank with thermal oil heating/electric heating system

7. Mixing Tower: 2000kg/batch twin shaft mixer, 2*37kW motor

8. Pneumatic System: screw air compressor (optional 600-2000L air storage tank)

9. Hot Asphalt Storage Bin: 40t, 60t, 80t bottom placed or side placed bin (optional)

10. Control System: fully automatic computer control (IPC+PLC+Monitor+Laser Printer+Air Conditioner)

|

Model |

LB800 |

LB1000 |

LB1500 |

LB2000 |

LB3000 |

LB4000 |

|

|

Capacity |

64 t/h |

80 t/h |

120 t/h |

160 t/h |

240 t/h |

300 t/h |

|

|

Mixer Capacity |

800 kg |

1000 kg |

1500 kg |

2000 kg |

3000 kg |

4000kg |

|

|

Noise Control |

Working noise |

≤70dB(A) |

|||||

|

|

Environment noise |

≤80dB(A) |

|||||

|

Measuring Accuracy |

Aggregate |

±0.5% |

±0.5% |

±0.5% |

±0.5% |

±0.5% |

±0.5% |

|

|

Bitumen |

±0.25% |

±0.25% |

±0.25% |

±0.25% |

±0.25% |

±0.25% |

|

|

Filler |

±0.5% |

±0.5% |

±0.5% |

±0.5% |

±0.5% |

±0.5% |

|

Dust Remove Effect |

≤20mg/Nm3 |

||||||

|

Voltage |

220V/380V-50HZ(Adjustable) |

||||||

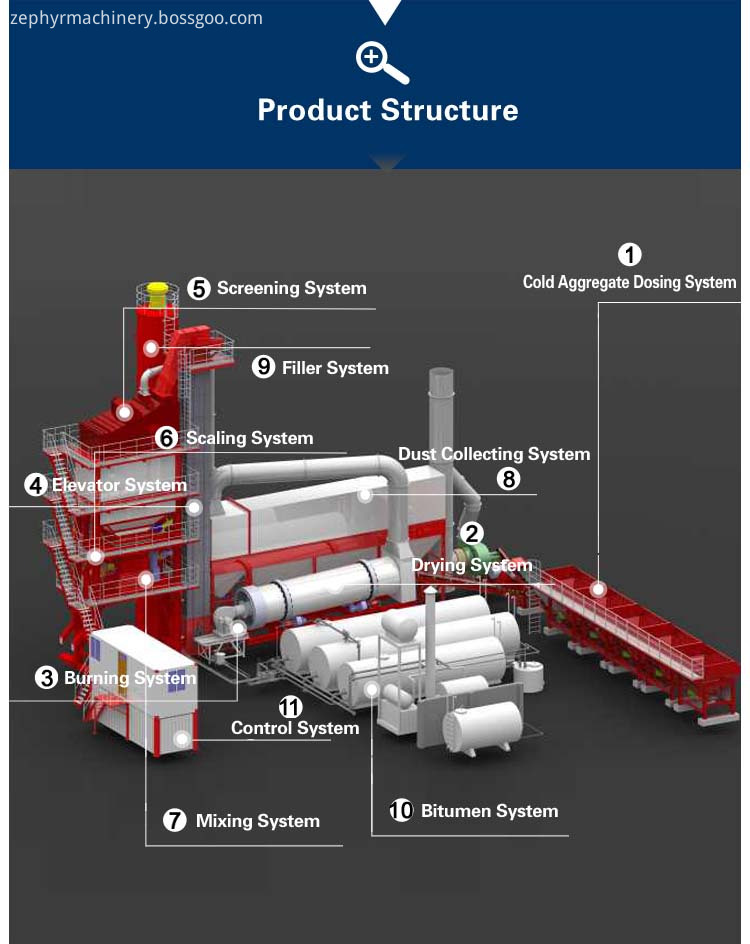

Cold aggregate system Drying System

Dust collector system Mixing tower

Filler supply system Control room

Our Service

Our company

Harbin Zephyr Trading Co.,Ltd locates in the north of China, province Heilongjiang,city Harbin.This is an international trading company mainly exports large road machinery such as:asphalt mixing plant,concrete mixing plant,crushing and screening production line and Excavator,Loader,Bulldozer,Truck Crane ,Concrete mixer truck,Dump Truck,Asphalt Paver ,Asphalt rolling machine etc construction machinery and so on...

As one of the first professional supplier of asphalt mixing plant and concrete mixing plant in China,we have always given attention to maintaining our higher level quality control and service , and we have reveived the ISO9001,CE,SGS etc certificates.Our equipment has exported to 35 countries,including:Russia,India,Bangladesh,Ghana etc.

If you have any inquiry about the concrete mixing plant or constructions road machinery,please fell free to contact us,We are always warmly welcome you to come and look forward to our meeting!

FAQ

Q1: How to use this asphalt mixing plant?

A: As a professional asphalt mixing plant supplier,we have many professional engineers,

they will go to clients` site for guiding the installation and test-running;also can teach you how to use the

mixing plant properly.

Q2: Can you sent me some spare parts freely?

A:Generally speaking,we usually sent customers the wearing parts when shipping the product,

but if you have a large order,we will consider to sent you some spare parts freely

Q3: What is the delivery time?

A:Usually can deliver within 35-50 work days

Contact Us

If you have any idea, pls contact us!

We can provide the customized service for you!

Harbin, Heilongjiang, China

- Manufacturer

- Trade Company

- Platform Certification

- SGS Certification

- Online Expo

Send your inquiry to this supplier