1 / 5

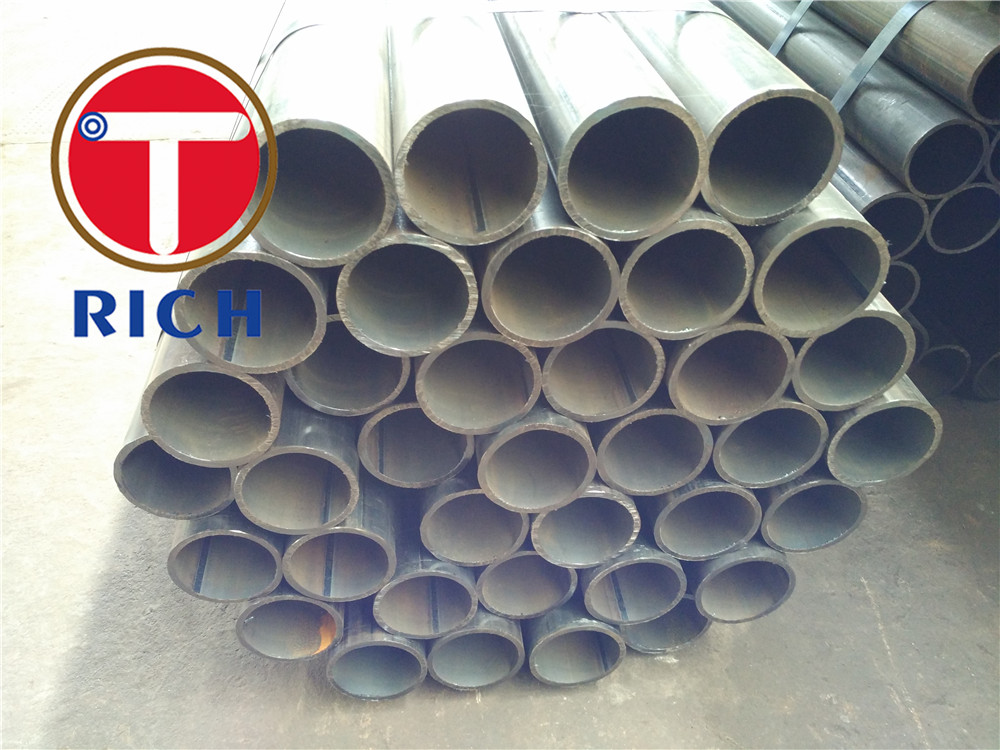

EN10217-5 P235GH P265GH 16Mo3 Submerged Arc Welded Steel Tubes with Non-ally and Alloy Steel

| Model No. : | EN10217-5 |

|---|---|

| Brand Name : | Torich |

| Type : | Welded |

Ningbo, Zhejiang, China

- Distributor/Wholesaler

- Manufacturer

- Service

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

- Video

Product description

EN10217-5 P235GH P265GH 16Mo3 Submerged Arc Welded Steel Tubes with Non-ally and Alloy Steel

EN10217-5 Welded steel tubes for pressure purposes - Technical delivery conditions -

Part 5: Submerged arc welded non-alloy and alloy steel tubes with specified elevated temperature properties

Material:

Fully killed steel, Fine grain steel with a ferritic grain size.

Steel Names:

In accordance with EN10027-1 and CR10260

Manufacture:

HFW High frequency welded

SAW Submerged arc welded - longiditudinal seam - SAWH

- helical seam - SAWL

Welding Procedure:

Testing and inspection of the welding procedure for submerged ard welded(SAW) tubes are witnessed and approved in accordance with EN10217-1

Apperance and General:

The weld areas are free from cracks, lack of fusion and lack of penetration

The tubes are free from external surface defects that can be detected by visual examination.

Leak-tigthtness:

The Tubes shall pass a hydrostatic test or electromagnetic test for leak-tightness

Non-Destructive Testing:

The full length of the weld seam of all EW and BW tubes ahll be subjected to a Non-Destructive test for detection of longitudinal imferfections

The full length of the weld seaml of all SAW tubes shall be subjuected to a Non-Destructive test for the detection of imperfections.

Straightness:

The deviation from straightness, of any tube length L, shall not exceed 0.0015L.

Deviations from Straightness over any one meter length shall not exeed 3mm.

Preparation of ends:

Tubes shall be delivered with square cut ends. The ends shall be free from excessive burrs.

Chemical compsotion:

| Steel Grade |

C |

Si max |

Mn |

P max |

S max |

Cr max |

Mo |

Ni max |

Al |

Cu max

|

Nb max

|

Ti max

|

V max

|

Cr+Cu+ Mo+Ni max |

|

| Steel name | Steel number | ||||||||||||||

| P235GH | 1.0345 | ≤0.16 | 0.35 | ≤1.20 | 0.025 | 0.020 | 0.30 | ≤0.08 | 0.30 | ≥0.020 | 0.30 | 0.010 | 0.03 | 0.02 | 0.70 |

| P265GH | 1.0425 | ≤0.20 | 0.40 | ≤1.40 | 0.025 | 0.020 | 0.30 | ≤0.08 | 0.30 | ≥0.020 | 0.30 | 0.010 | 0.03 | 0.02 | 0.70 |

| 16Mo3 | 1.5415 |

0.12 to 0.20 |

0.35 | 0.40to0.90 | 0.025 | 0.020 | 0.30 |

0.25 to 0.35 |

0.30 | ≥0.040 | 0.30 | - | - | - |

- |

China Welded Steel Pipe manufacturer, choose the high quality Spiral Welded Steel Pipe, High Frequency Welded Steel Pipe, Black Carbon Steel Welded Pipe, etc.

Ningbo, Zhejiang, China

- Distributor/Wholesaler

- Manufacturer

- Service

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

- Video

Send your inquiry to this supplier