1 / 1

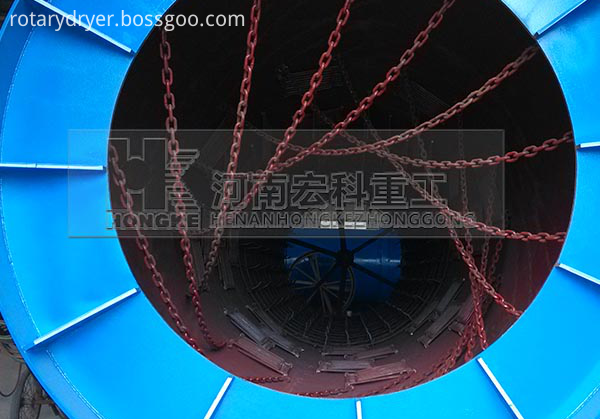

Electroplating Sludge Rotary Dryer

| Model No. : | Φ600*8m-Φ3500*25m |

|---|---|

| Brand Name : | Hongke |

Zhengzhou, Henan, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

Product description

Rotary sludge dryer, which belongs to air energy heat pump assembly line drying equipment, is economical, energy saving and environmental protection. Sludge dryer can also be widely used in activated sludge drying, sewage sludge drying, petrochemical sludge drying, papermaking sludge drying, Electroplating sludge drying, municipal sludge drying, and all kinds of sludge and high humidity materials such as slag drying. The operation of sludge drying equipment is simple and practical, the dust-proof seal is good, the maintenance is convenient, and it is widely used.

Working Principle of Electroplating Sludge Dryer

The hollow shaft of the electroplating sludge dryer is packed with wedge-shaped hollow blades, and the heat medium steam flows from the hollow axial flow to the blade. The heat transfer area in the unit effective volume is very high. The heat transfer medium passes through the rotary joint, and the flow is made up of the shell jacket and the hollow mixing shaft, which have different internal structures according to the type of the heat medium, so as to ensure the best heat transfer effect. While the blades and jackets are heated with heat medium, the upper part of the outlet is simultaneously wetted, which increases the drying strength of the machine. The evaporated moisture is taken out of the drying equipment by the draught fan.

Characteristics of Electroplating Sludge Dryer

1 .Adopting an air energy pipeline sludge dryer , only needing to adjust the time through the PCL control panel , so that the whole drying process can be fully completed without the need of personnel watching , so that the drying efficiency is greatly improved .

2. The intelligent electronic expansion valve control is used instead of the thermal expansion valve technology. At the same time, the opening of the electronic expansion valve is controlled by the innovation of the undercooling degree, the fuzzy PID accords with the control algorithm, the intelligent control of the opening degree of the electronic expansion valve is realized, and the refrigerant flow control is realized. Thus the intelligent control of drying room temperature and defrosting can be realized.

3.The enthalpy difference of the main circulation is increased, the exhaust temperature is reduced by increasing the gas supply channel, and the heat production capacity of the heat pump unit is increased, the cop value is increased, and the heat production requirement in the low temperature environment is satisfied, and the energy saving and high efficiency are achieved by adopting the secondary compression technology of the jet enthalpy increase.

4. It innovates the horizontal circulation air path design of the fresh air, return air, hot air seal road, which realizes the automatic control of wind direction, air volume, wind speed, thus realizes the heat exchange between the return air and fresh air in the best condition; At the same time, the technology of strong convection and forced hot air 360 circulation in drying room is innovated to avoid any hot air dead angle and to increase the temperature and drying rate of drying room.

Technical Parameters of Sludge Dryer

|

Specification |

Handling capacity (t/h) |

Feeding Moisture (%) |

Output Moisture (%) |

Mainframe Motor (kw) |

Reducer (JZQ) |

| Φ600*8m | 0.5-1.2 | 70±5 | 15±5 | 2.2 | 200 |

| Φ600*10m | 0.5-1.5 | 70±5 | 70±5 | 3 | 250 |

| Φ800*8m | 0.8-1.5 | 70±5 | 70±5 | 5.5 | 250 |

| Φ800*10m | 0.8-1.8 | 70±5 | 70±5 | 5.5 | 250 |

| Φ1000*10m | 1.0-3.5 | 70±5 | 70±5 | 7.5 | 250 |

| Φ1000*12m | 1.0-3.8 | 70±5 | 70±5 | 7.5 | 250 |

| Φ1200*12m | 1.2-3.5 | 70±5 | 70±5 | 11 | 350 |

| Φ1200*15m | 1.2-4.0 | 70±5 | 70±5 | 11 | 350 |

| Φ1500*15m | 2.0-5.5 | 70±5 | 70±5 | 22 | 500 |

| Φ1800*16m | 3.5-6.5 | 70±5 | 70±5 | 22 | 500 |

| Φ1800*20m | 4.0-6.5 | 70±5 | 70±5 | 30 | 650 |

| Φ2000*20m | 5.0-7.0 | 70±5 | 70±5 | 37 | 650 |

| Φ2000*22m | 5.0-.7.0 | 70±5 | 70±5 | 37 | 650 |

| Φ2400*22m | 5.5-8.0 | 70±5 | 70±5 | 45 | 650 |

| Φ2400*26m | 7.0-16 | 70±5 | 70±5 | 55 | 750 |

| Φ3000*20m | 15-25 | 70±5 | 70±5 | 55 | 850 |

| Φ3000*25m | 15-30 | 70±5 | 70±5 | 75 | 850 |

| Φ3300*25m | 25 | 70±5 | 70±5 | 75 | 1000 |

| Φ3500*25m | 30 | 70±5 | 70±5 | 90 | 1000 |

Zhengzhou, Henan, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

Send your inquiry to this supplier