1 / 1

Electromagnetic stirring 2016 @hebei

Get Latest Price

Send Inquiry

| Model No. : | JBDZ series |

|---|---|

| Brand Name : | IDEA |

Shijiazhuang Idea Electric Co., Ltd.

You might also like

Product description

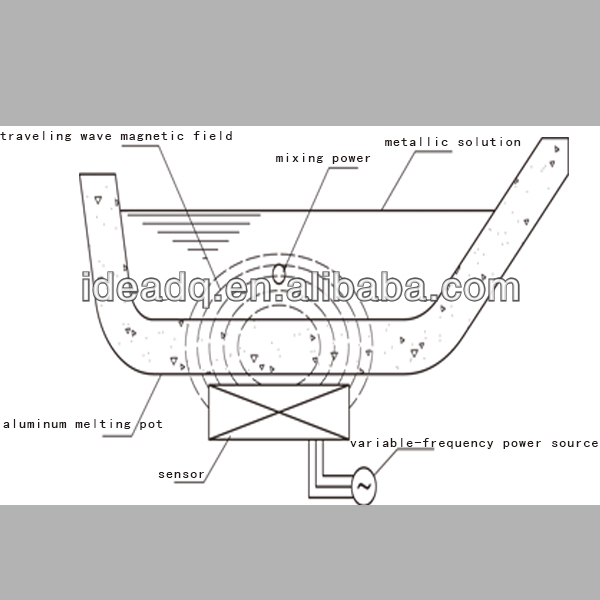

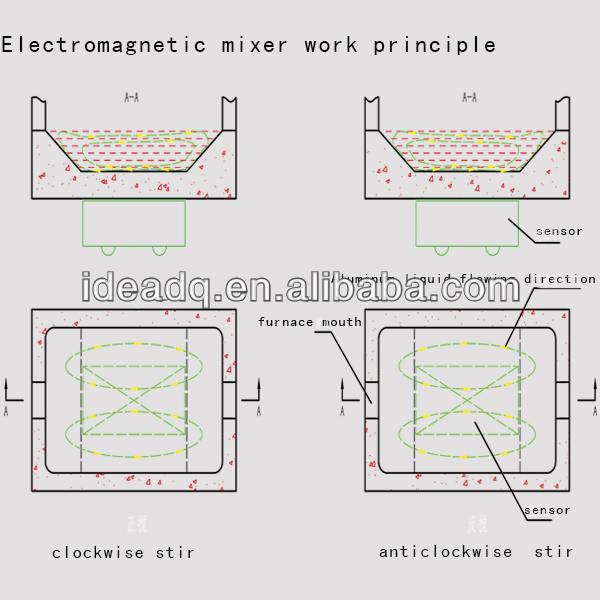

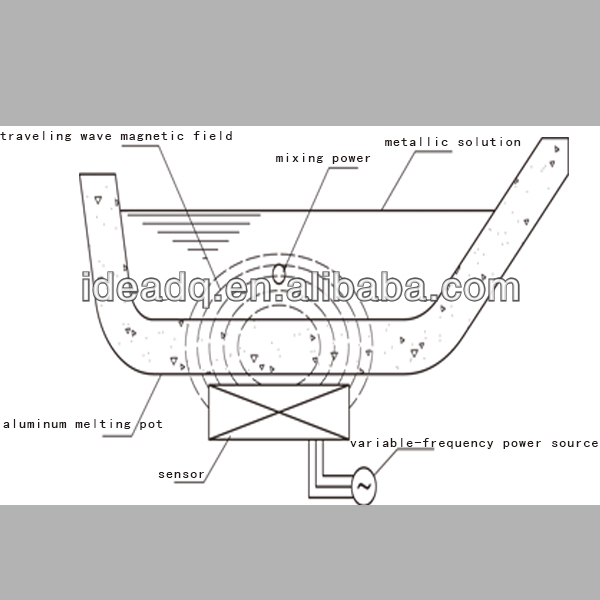

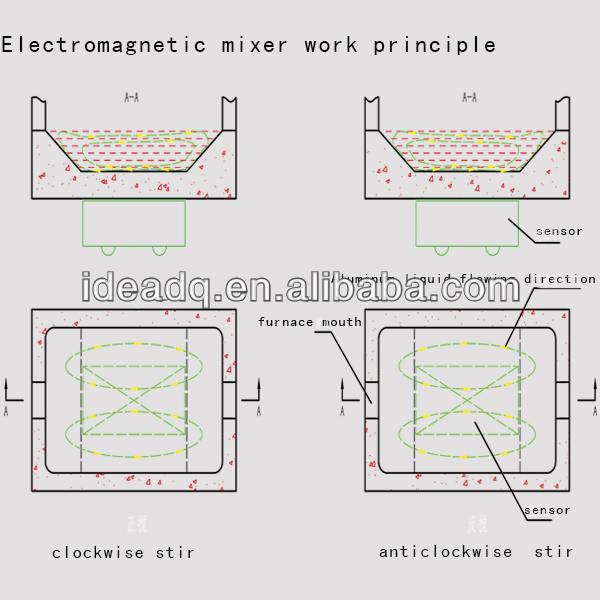

"Stirring" aluminum smelting process is an important process measures. Mixing full or not directly determine the aluminum products’ quality. Mixing way has artificial stirring, gas stirring, mechanical agitation, electromagnetic stirring etc. with electromagnetic stirring because of its fully mixing, simple operation and grew in popularity. Inductive electromagnetic stirring device is a kind of application principle of electromagnetic induction and produce a magnetic field in the role of molten aluminium liquid so that melting liquid has regular exercise equipment. In the electromagnetic stirring subject device-to low frequency current of sensors, in order to form the traveling wave alternating magnetic field, melting liquid in the influence of the magnetic field of potential and current, the induced current and magnetic fields interact to produce the electromagnetic force, make the melting liquid regular exercise, in order to achieve the purpose of mixing. By changing the direction of the field and the traveling wave strength, can effectively regulate the melting liquid mixing direction and stir intensity.  Electromagnetic mixer work principle

Electromagnetic mixer work principle  The advantages of electromagnetic stirring Our company is professional producing the 2-150 tons of various kinds of specifications with aluminum melting pot electromagnetic stirring device, is the non-ferrous metal industry electromagnetic products professional manufacturers and suppliers, the product series: furnace bottom inductive electromagnetic stirring device, lateral inductive electromagnetic stirring device, renewable aluminum industry with double room furnace electromagnetic blender, etc. Electromagnetic stirring technology application can be obtained as follows effect: 1. Can make the melt alloy components uniform. General electromagnetic stirring device (no more than 20 minutes), can the whole furnace of various elements of the aluminium chemical composition of the relative deviation is less than 5%, can satisfy the almost all alloy to composition uniformity of the requirements. 2. The mixing process not destroy the oxidation layer, can reduce the melt hydrogen absorbing and oxygen, ensure the quality of the melt, and reduce the loss (relative value) 20 to 25%. 3. Can make the top and bottom of the melt temperature uniformity. General mixing ten minutes to the limit of the melt temperature can drop to less than 5 °C. So can reduce melting temperature, can improve the melt bottom alloying melting degree, in lower melting again at the same time can reduce the degree of damage. 4. In the process of aluminum ingots re-melting using electromagnetic stirring technology can shorten the time of smelting, improve work efficiency, reduce energy consumption, according to data provided by the already, can reduce energy consumption (improve efficiency) 20 to 30%. 5. No pollution aluminum melting liquid. This has the important meaning for high purity aluminium and the iron control strict alloy. 6. Can reduce the labor intensity, and improve working con. The electromagnetic stirrer application field

The advantages of electromagnetic stirring Our company is professional producing the 2-150 tons of various kinds of specifications with aluminum melting pot electromagnetic stirring device, is the non-ferrous metal industry electromagnetic products professional manufacturers and suppliers, the product series: furnace bottom inductive electromagnetic stirring device, lateral inductive electromagnetic stirring device, renewable aluminum industry with double room furnace electromagnetic blender, etc. Electromagnetic stirring technology application can be obtained as follows effect: 1. Can make the melt alloy components uniform. General electromagnetic stirring device (no more than 20 minutes), can the whole furnace of various elements of the aluminium chemical composition of the relative deviation is less than 5%, can satisfy the almost all alloy to composition uniformity of the requirements. 2. The mixing process not destroy the oxidation layer, can reduce the melt hydrogen absorbing and oxygen, ensure the quality of the melt, and reduce the loss (relative value) 20 to 25%. 3. Can make the top and bottom of the melt temperature uniformity. General mixing ten minutes to the limit of the melt temperature can drop to less than 5 °C. So can reduce melting temperature, can improve the melt bottom alloying melting degree, in lower melting again at the same time can reduce the degree of damage. 4. In the process of aluminum ingots re-melting using electromagnetic stirring technology can shorten the time of smelting, improve work efficiency, reduce energy consumption, according to data provided by the already, can reduce energy consumption (improve efficiency) 20 to 30%. 5. No pollution aluminum melting liquid. This has the important meaning for high purity aluminium and the iron control strict alloy. 6. Can reduce the labor intensity, and improve working con. The electromagnetic stirrer application field  ♦TAGC ♦ SNTO ♦ Shangdong ChuangXin ♦ Shangdong QiXing ♦ Shangdong Sangsung ♦ Taiwan LiuFeng ♦ Henan Wonder

♦TAGC ♦ SNTO ♦ Shangdong ChuangXin ♦ Shangdong QiXing ♦ Shangdong Sangsung ♦ Taiwan LiuFeng ♦ Henan Wonder

Electromagnetic mixer work principle

Electromagnetic mixer work principle  The advantages of electromagnetic stirring Our company is professional producing the 2-150 tons of various kinds of specifications with aluminum melting pot electromagnetic stirring device, is the non-ferrous metal industry electromagnetic products professional manufacturers and suppliers, the product series: furnace bottom inductive electromagnetic stirring device, lateral inductive electromagnetic stirring device, renewable aluminum industry with double room furnace electromagnetic blender, etc. Electromagnetic stirring technology application can be obtained as follows effect: 1. Can make the melt alloy components uniform. General electromagnetic stirring device (no more than 20 minutes), can the whole furnace of various elements of the aluminium chemical composition of the relative deviation is less than 5%, can satisfy the almost all alloy to composition uniformity of the requirements. 2. The mixing process not destroy the oxidation layer, can reduce the melt hydrogen absorbing and oxygen, ensure the quality of the melt, and reduce the loss (relative value) 20 to 25%. 3. Can make the top and bottom of the melt temperature uniformity. General mixing ten minutes to the limit of the melt temperature can drop to less than 5 °C. So can reduce melting temperature, can improve the melt bottom alloying melting degree, in lower melting again at the same time can reduce the degree of damage. 4. In the process of aluminum ingots re-melting using electromagnetic stirring technology can shorten the time of smelting, improve work efficiency, reduce energy consumption, according to data provided by the already, can reduce energy consumption (improve efficiency) 20 to 30%. 5. No pollution aluminum melting liquid. This has the important meaning for high purity aluminium and the iron control strict alloy. 6. Can reduce the labor intensity, and improve working con. The electromagnetic stirrer application field

The advantages of electromagnetic stirring Our company is professional producing the 2-150 tons of various kinds of specifications with aluminum melting pot electromagnetic stirring device, is the non-ferrous metal industry electromagnetic products professional manufacturers and suppliers, the product series: furnace bottom inductive electromagnetic stirring device, lateral inductive electromagnetic stirring device, renewable aluminum industry with double room furnace electromagnetic blender, etc. Electromagnetic stirring technology application can be obtained as follows effect: 1. Can make the melt alloy components uniform. General electromagnetic stirring device (no more than 20 minutes), can the whole furnace of various elements of the aluminium chemical composition of the relative deviation is less than 5%, can satisfy the almost all alloy to composition uniformity of the requirements. 2. The mixing process not destroy the oxidation layer, can reduce the melt hydrogen absorbing and oxygen, ensure the quality of the melt, and reduce the loss (relative value) 20 to 25%. 3. Can make the top and bottom of the melt temperature uniformity. General mixing ten minutes to the limit of the melt temperature can drop to less than 5 °C. So can reduce melting temperature, can improve the melt bottom alloying melting degree, in lower melting again at the same time can reduce the degree of damage. 4. In the process of aluminum ingots re-melting using electromagnetic stirring technology can shorten the time of smelting, improve work efficiency, reduce energy consumption, according to data provided by the already, can reduce energy consumption (improve efficiency) 20 to 30%. 5. No pollution aluminum melting liquid. This has the important meaning for high purity aluminium and the iron control strict alloy. 6. Can reduce the labor intensity, and improve working con. The electromagnetic stirrer application field  ♦TAGC ♦ SNTO ♦ Shangdong ChuangXin ♦ Shangdong QiXing ♦ Shangdong Sangsung ♦ Taiwan LiuFeng ♦ Henan Wonder

♦TAGC ♦ SNTO ♦ Shangdong ChuangXin ♦ Shangdong QiXing ♦ Shangdong Sangsung ♦ Taiwan LiuFeng ♦ Henan Wonder Send your inquiry to this supplier

Send Inquiry