Video

1 / 4

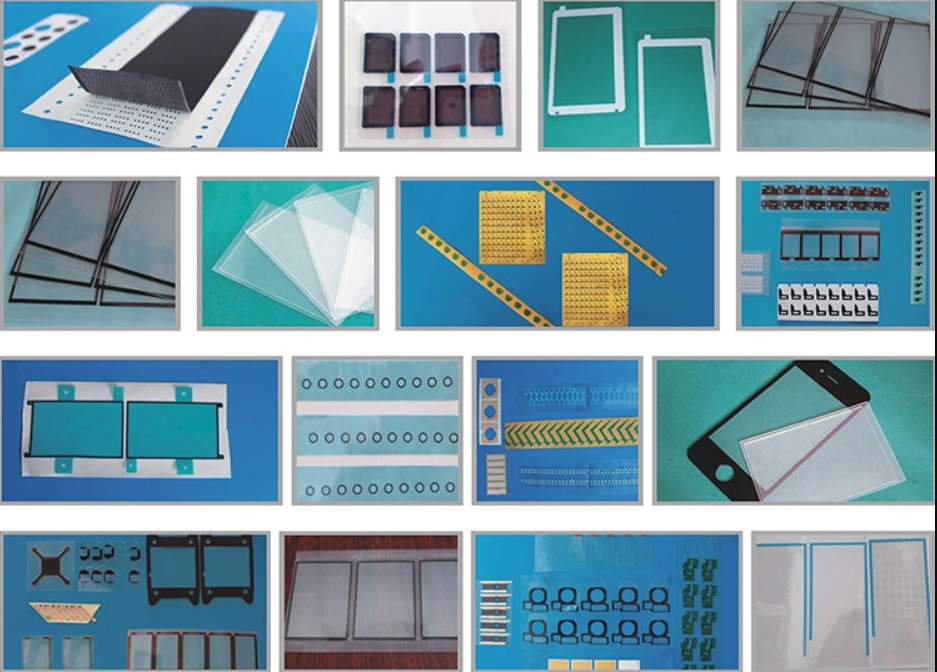

Electric conductive tape die cutting machine

Model:

- ENZO-200

Power (Watts):

- 3.5KW

Options:

- Electrically adjust turning way

- Jog/Discontinuous/Continuous press styple

- Less 0.1mm feeding precision

- ±0.03mm die cutting precision

| Model No. : | ENZO-200 |

|---|---|

| Brand Name : | Flying Man |

| Applicable industry : | Manufacturing Plant,Printing Shops,Other,Advertising Company |

Suzhou, Jiangsu, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

- Online Expo

Product description

Electric conductive tape die cutting machine

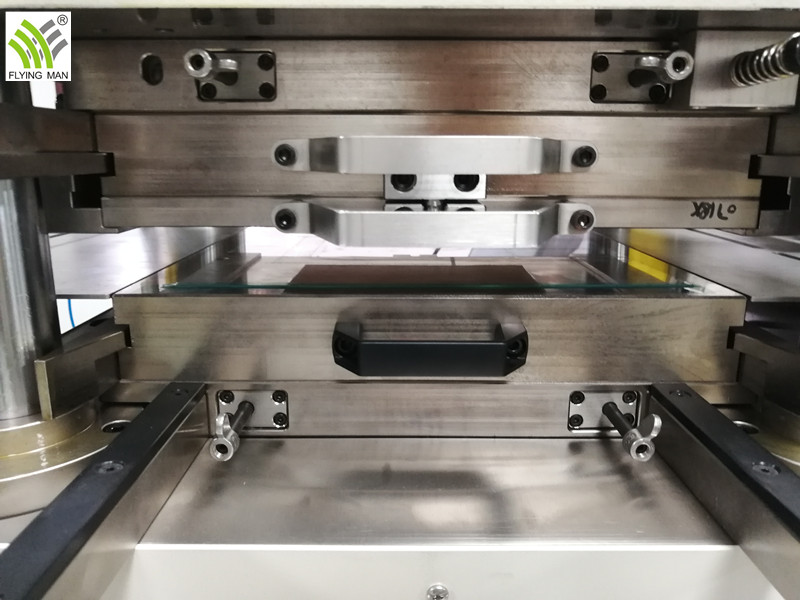

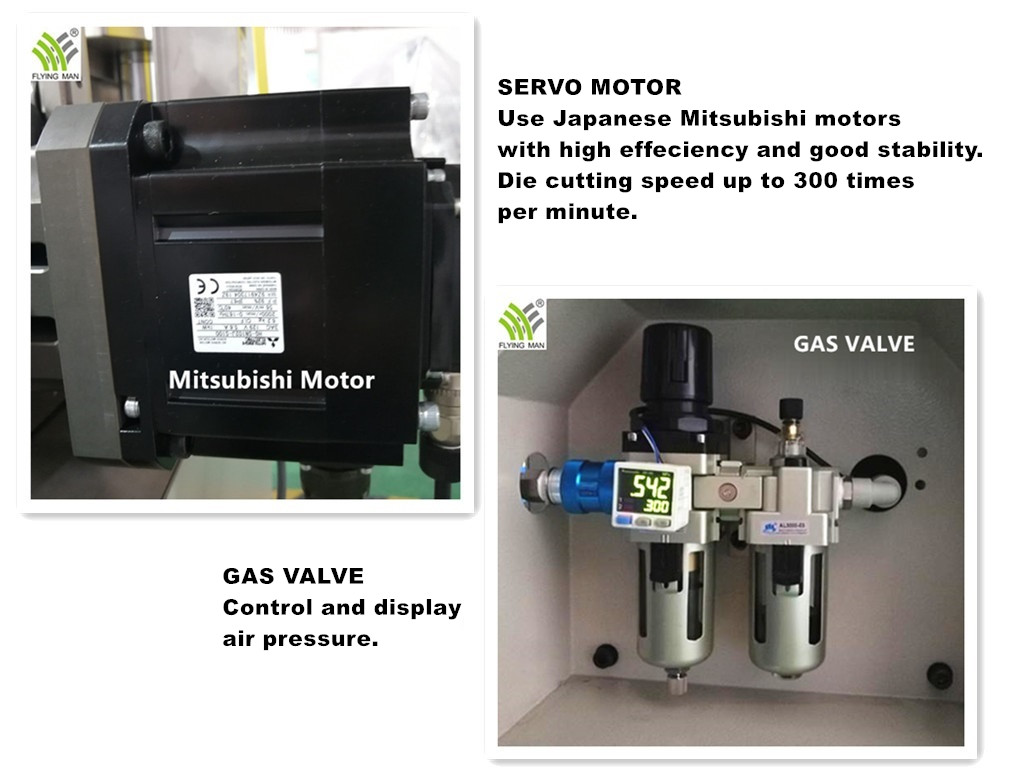

Flying Man high speed precision die cutting machines developed by flying man team independently have the following advantages, to adopt Mitsubishi brand motors and PLC, Schneider brand Low voltage electrical apparatus and power supply which make the machine more stable. This electric conductive tape die cutting machine has below advantages: high speed, precision and stable performance characteristics, improve the machine operation more efficiency, save a lot of labor; At the same time, the machine is low noise, easy to maintain, easy to operate and safe. Unique hole positioning and timely correcting function to ensure repeated die-cutting and accurate positioning, punching accuracy control within 0.04mm, kiss cut base material up to 0.025mm precision.

Industry Highest Performance Characteristics

- Perfect flatness, it can kiss cut to 0.025 mm base material. - Any acceleration and deceleration in the interval of 30-100 times/minute does not affect the cutting depth.

- The operation interface is extremely simple and easy to use.

|

SPECIFICATIONS FOR HIGH SPEED PRECISION FLATBED DIE CUTTING MACHINE

|

|

|

|

|||

|

Model

|

ENZO-200

|

Maximum Feeding Speed

|

30 mm/min

|

|||

|

Press Force

|

5T

|

Feeding Accuracy

|

< 0.1 mm

|

|||

|

Cutting stroke

|

24 mm

|

Feeding Roller

|

PU/NBR

|

|||

|

Maximum Running Speed

|

300 times/min

|

Feeding Driven

|

Servo Motors

|

|||

|

Stroke Adjustment

|

±5 mm

|

Lubricate method

|

Fully Automatic Central Lubrication System

|

|||

|

Shut Height of Stell Mould

|

105 mm

|

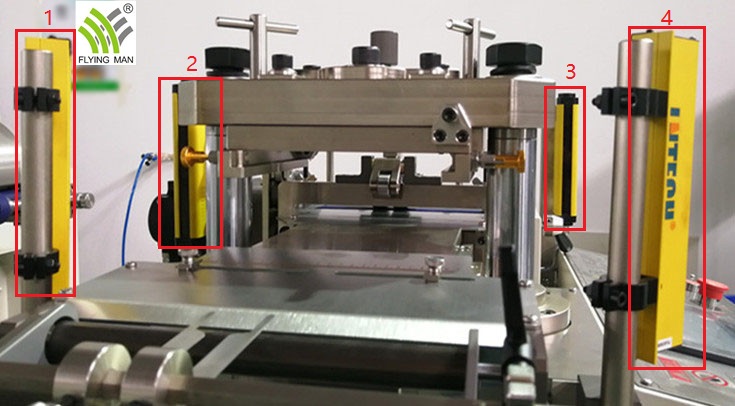

Protection

|

3 Optical Safety light curtain

|

|||

|

Maximum die cutting size of Steel Mould(L*W)

|

120 x 150 mm

|

Power Supply

|

380v 3.5kw

|

|||

|

Turning Way

|

Electrically Adjust

|

Machine Weight

|

1000 kgs

|

|||

|

Press Style

|

Jog/Single/Continuous

|

Air Source Specification

|

0.5-0.6 mpa

|

|||

|

Type of Mould

|

Plastic board mould, Chemical sculpture mould, Metal mould

|

Maximum size of mode(L*W)

|

200 x 180 mm

|

|||

|

Maximum Feeding width

|

200mm

|

Machine Size (L*W*H)

|

1200 x 900 x 1250 mm

|

|||

Training service

After Sales Service

Video

Suzhou, Jiangsu, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

- Online Expo

Send your inquiry to this supplier