1 / 6

Efficient sand making and screening plant for construction material and limestone crushing used in cement production plant

Get Latest Price

Send Inquiry

| Model No. : | PL |

|---|---|

| Brand Name : | Jiangtai sand making and screening plant |

Zhengzhou Jiangtai Heavy Industrial Machinery Co., Ltd.

You might also like

Product description

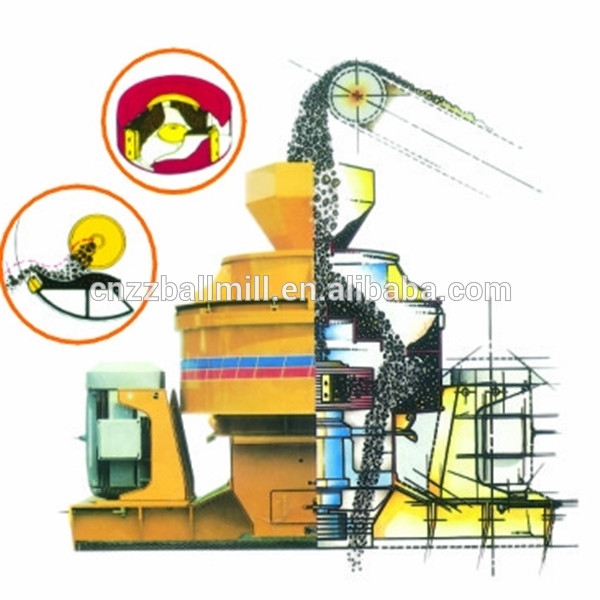

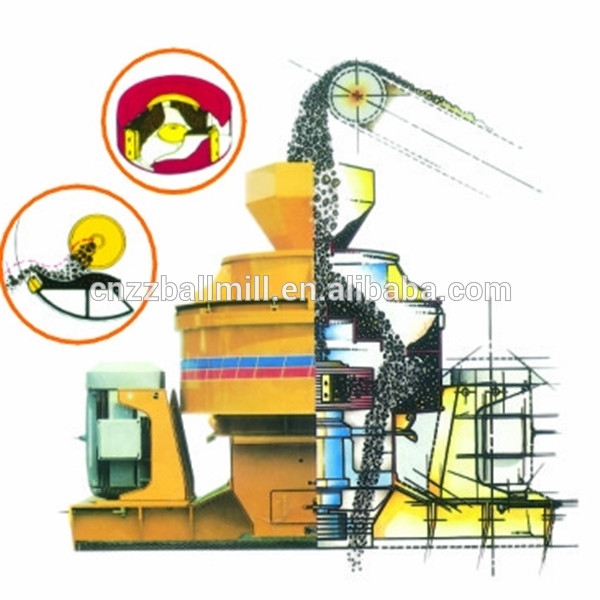

Product Description Product description of production plant: Sand making and screening plant ususally consists of vibrating feeder, jaw crusher (optional), sand maker, belt conveyors and vibrating screens and so on, the quantity of crshing equipment needed is mainly depend on the condition from the users, such as the original stone size, crushing capacity and the finished sizes needed, Zhengzhou Jiangtai Heavy Industrial Machinery Co., LTD can provide all of these equipments and after sale services till the users can produce ideal products on the sites. For sand making and screening plant, sand maker or vsi type sand maker is needed so that the final sizes can be less than 5 mm or setted as the required sizes, and for aggregate production plant, impact crusher or hammer crusher is needed. Our shaft crusher is especially efficient to crush harder and causticity materials, such as carborundum, emery, and magnesium sand. PL Series sand making machine is one of the most advanced impact crushers nowadays. Personalized design is used in upper cap, sand making machine is easy and convenient to maintain and replace spare parts. Sand Making Machine is our sole patent using central feeding & central cascade feeding, which can be changed based on customers' needs.  working principle of sand cmaking and screening plant : The entire center feeding: Material falls the feed hopper, then enters the high-speed rotary sling wheel from center feeding hole, which is speeded immediately in the sling wheel. The speed can reach several dozens times of the gravity acceleration. Then sand making machine is thrown from the sling wheel. First, it is crushed with other rebounded material fell freely from the sling wheel. Then both of them are impacted to the material lining (rock-rock) or strike back block (rock-iron), rebounded and stroke to the top of eddy cavity of vertical shaft crusher in the inclined-up direction. Then it moves along deflection-down, and forms a continuous material curtain with the material from the impellers passage. Just like this, the material is stroke, rubbed, crushed twice or more, then is discharged from the down discharging hole.

working principle of sand cmaking and screening plant : The entire center feeding: Material falls the feed hopper, then enters the high-speed rotary sling wheel from center feeding hole, which is speeded immediately in the sling wheel. The speed can reach several dozens times of the gravity acceleration. Then sand making machine is thrown from the sling wheel. First, it is crushed with other rebounded material fell freely from the sling wheel. Then both of them are impacted to the material lining (rock-rock) or strike back block (rock-iron), rebounded and stroke to the top of eddy cavity of vertical shaft crusher in the inclined-up direction. Then it moves along deflection-down, and forms a continuous material curtain with the material from the impellers passage. Just like this, the material is stroke, rubbed, crushed twice or more, then is discharged from the down discharging hole.  Characteristics of sand crushing (Sand Making Machine) which can be used in sand making and screening plant: 1. Simple structure and low operating cost;

Characteristics of sand crushing (Sand Making Machine) which can be used in sand making and screening plant: 1. Simple structure and low operating cost;

2. High crushing ratio with low consumption;

3. Function of fine crushing and crude grinding;

4. Slightly influenced by moisture content of material, and the max moisture content is about 8%;

5. More suitable for crushing mid-hardness and high hardness materials;

6. Cubic shape of final products, high density of piling up and low iron pollution;

7. More wearable and easier maintenance;

8. Low working noise (lower than 75 decibel) and light dust pollution. Main Technical Parameter of sand maker which can be used in sand making and screening plant: Packaging & Shipping Factory machine:

Packaging & Shipping Factory machine:  Delivery:

Delivery:  Our Services According to customers' demand, we supply the services in a flexible way not only the traditional services but also the internet online services. Our engineer is 24 hours online. We try our best to carve out maket and provide services all the time. Before customers purchase, we will send our engineers to customers site to design the best flow chart. After purchase, we will send the engineer to guide to install the machine, take trial run. Try our best to provide our customers with service of high quality and efficiency. We welcome customers from home and abroad to visit our company and carry put cooperation! Company Information About us Henan JiangTai Mining Machinery Co.,Ltd , is one of the first garden like factories located in ZhengZhou which is one of the eight historic cities in China. Since established, We have passed ISO9001:2008 quality system authentication and CE certificate. The company has been taking the scientific management method of the modern enterprise, producing with meticulouscare and nonstop creation and developing to become a bright pearl and pacemaker of the mechanical industry. Main products Such as crushing equipment, sand making equipment, concentration, aerated autoclave concrete equipment, coal equipment, milling equipment, burning free brick equipment. gravel equipment, processing equipment, cement equipment, metal magnesium equipment , rotary kiln, rotary dryer, cement ball mill, sand making and screening plant, etc. If you are interested in our products and want to know information from us please feel free to contact us. You can send email or contact on trademanager, and I will reply asap.

Our Services According to customers' demand, we supply the services in a flexible way not only the traditional services but also the internet online services. Our engineer is 24 hours online. We try our best to carve out maket and provide services all the time. Before customers purchase, we will send our engineers to customers site to design the best flow chart. After purchase, we will send the engineer to guide to install the machine, take trial run. Try our best to provide our customers with service of high quality and efficiency. We welcome customers from home and abroad to visit our company and carry put cooperation! Company Information About us Henan JiangTai Mining Machinery Co.,Ltd , is one of the first garden like factories located in ZhengZhou which is one of the eight historic cities in China. Since established, We have passed ISO9001:2008 quality system authentication and CE certificate. The company has been taking the scientific management method of the modern enterprise, producing with meticulouscare and nonstop creation and developing to become a bright pearl and pacemaker of the mechanical industry. Main products Such as crushing equipment, sand making equipment, concentration, aerated autoclave concrete equipment, coal equipment, milling equipment, burning free brick equipment. gravel equipment, processing equipment, cement equipment, metal magnesium equipment , rotary kiln, rotary dryer, cement ball mill, sand making and screening plant, etc. If you are interested in our products and want to know information from us please feel free to contact us. You can send email or contact on trademanager, and I will reply asap.

FAQ Q: Can I visit your factory?

FAQ Q: Can I visit your factory?

A: Yes. Many domestic and international customers visit our factory every year.

Q: How long is the warranty of your equipment? Do you supply spare parts?

A: Our warranty period is one year generally. We can supply spare parts.

Q: Do you provide after-sale service?

A: Yes. We have a professional after-sale service team to promptly and thoroughly solve your problems.

Q: Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passports.

Q: Do you provide beneficiation flow chart?

A: Yes. Our experienced engineers are specialized in designing process flow for various ores beneficiation, including iron ore, tin ore, copper ore, gold ore, lead zinc ore, manganese ore, etc.

Q: Can you test our samples?

A: Yes. You can send your samples to us for test and analysis.

Q: Have you made the whole ore dressing lines?

A: Yes. We have made many large ore dressing lines at home and abroad.

working principle of sand cmaking and screening plant : The entire center feeding: Material falls the feed hopper, then enters the high-speed rotary sling wheel from center feeding hole, which is speeded immediately in the sling wheel. The speed can reach several dozens times of the gravity acceleration. Then sand making machine is thrown from the sling wheel. First, it is crushed with other rebounded material fell freely from the sling wheel. Then both of them are impacted to the material lining (rock-rock) or strike back block (rock-iron), rebounded and stroke to the top of eddy cavity of vertical shaft crusher in the inclined-up direction. Then it moves along deflection-down, and forms a continuous material curtain with the material from the impellers passage. Just like this, the material is stroke, rubbed, crushed twice or more, then is discharged from the down discharging hole.

working principle of sand cmaking and screening plant : The entire center feeding: Material falls the feed hopper, then enters the high-speed rotary sling wheel from center feeding hole, which is speeded immediately in the sling wheel. The speed can reach several dozens times of the gravity acceleration. Then sand making machine is thrown from the sling wheel. First, it is crushed with other rebounded material fell freely from the sling wheel. Then both of them are impacted to the material lining (rock-rock) or strike back block (rock-iron), rebounded and stroke to the top of eddy cavity of vertical shaft crusher in the inclined-up direction. Then it moves along deflection-down, and forms a continuous material curtain with the material from the impellers passage. Just like this, the material is stroke, rubbed, crushed twice or more, then is discharged from the down discharging hole.  Characteristics of sand crushing (Sand Making Machine) which can be used in sand making and screening plant: 1. Simple structure and low operating cost;

Characteristics of sand crushing (Sand Making Machine) which can be used in sand making and screening plant: 1. Simple structure and low operating cost; 2. High crushing ratio with low consumption;

3. Function of fine crushing and crude grinding;

4. Slightly influenced by moisture content of material, and the max moisture content is about 8%;

5. More suitable for crushing mid-hardness and high hardness materials;

6. Cubic shape of final products, high density of piling up and low iron pollution;

7. More wearable and easier maintenance;

8. Low working noise (lower than 75 decibel) and light dust pollution. Main Technical Parameter of sand maker which can be used in sand making and screening plant:

Packaging & Shipping Factory machine:

Packaging & Shipping Factory machine:  Delivery:

Delivery:  Our Services According to customers' demand, we supply the services in a flexible way not only the traditional services but also the internet online services. Our engineer is 24 hours online. We try our best to carve out maket and provide services all the time. Before customers purchase, we will send our engineers to customers site to design the best flow chart. After purchase, we will send the engineer to guide to install the machine, take trial run. Try our best to provide our customers with service of high quality and efficiency. We welcome customers from home and abroad to visit our company and carry put cooperation! Company Information About us Henan JiangTai Mining Machinery Co.,Ltd , is one of the first garden like factories located in ZhengZhou which is one of the eight historic cities in China. Since established, We have passed ISO9001:2008 quality system authentication and CE certificate. The company has been taking the scientific management method of the modern enterprise, producing with meticulouscare and nonstop creation and developing to become a bright pearl and pacemaker of the mechanical industry. Main products Such as crushing equipment, sand making equipment, concentration, aerated autoclave concrete equipment, coal equipment, milling equipment, burning free brick equipment. gravel equipment, processing equipment, cement equipment, metal magnesium equipment , rotary kiln, rotary dryer, cement ball mill, sand making and screening plant, etc. If you are interested in our products and want to know information from us please feel free to contact us. You can send email or contact on trademanager, and I will reply asap.

Our Services According to customers' demand, we supply the services in a flexible way not only the traditional services but also the internet online services. Our engineer is 24 hours online. We try our best to carve out maket and provide services all the time. Before customers purchase, we will send our engineers to customers site to design the best flow chart. After purchase, we will send the engineer to guide to install the machine, take trial run. Try our best to provide our customers with service of high quality and efficiency. We welcome customers from home and abroad to visit our company and carry put cooperation! Company Information About us Henan JiangTai Mining Machinery Co.,Ltd , is one of the first garden like factories located in ZhengZhou which is one of the eight historic cities in China. Since established, We have passed ISO9001:2008 quality system authentication and CE certificate. The company has been taking the scientific management method of the modern enterprise, producing with meticulouscare and nonstop creation and developing to become a bright pearl and pacemaker of the mechanical industry. Main products Such as crushing equipment, sand making equipment, concentration, aerated autoclave concrete equipment, coal equipment, milling equipment, burning free brick equipment. gravel equipment, processing equipment, cement equipment, metal magnesium equipment , rotary kiln, rotary dryer, cement ball mill, sand making and screening plant, etc. If you are interested in our products and want to know information from us please feel free to contact us. You can send email or contact on trademanager, and I will reply asap.

FAQ Q: Can I visit your factory?

FAQ Q: Can I visit your factory?A: Yes. Many domestic and international customers visit our factory every year.

Q: How long is the warranty of your equipment? Do you supply spare parts?

A: Our warranty period is one year generally. We can supply spare parts.

Q: Do you provide after-sale service?

A: Yes. We have a professional after-sale service team to promptly and thoroughly solve your problems.

Q: Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passports.

Q: Do you provide beneficiation flow chart?

A: Yes. Our experienced engineers are specialized in designing process flow for various ores beneficiation, including iron ore, tin ore, copper ore, gold ore, lead zinc ore, manganese ore, etc.

Q: Can you test our samples?

A: Yes. You can send your samples to us for test and analysis.

Q: Have you made the whole ore dressing lines?

A: Yes. We have made many large ore dressing lines at home and abroad.

Send your inquiry to this supplier

Send Inquiry