1 / 1

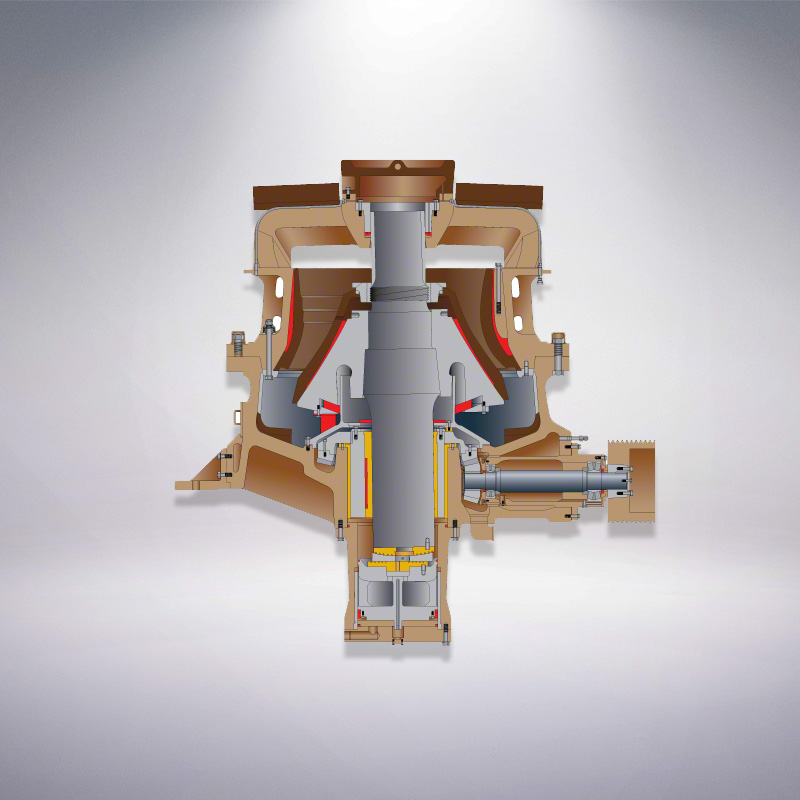

Eccentric wear plate for sandvik cone crusher

| Model No. : | H2800 H3800 H4800 H6800 H7800 H8800 |

|---|---|

| Certification: : | ISO9001:2008 |

Shenyang, Liaoning, China

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

- Video

Product description

Shenyang YYD Casting Co.,Ltd is specialised in producing all kinds of crusher spare parts, such as Upper Head Bushing,Lower Head Bushing,Frame Bush,Eccentric Bushing, Socket Liner, Wear Plate, Shaft Bushing as well as other crusher parts for numerous crusher brands, like Symons, Sandvik, Metso,Svedala ,Nordberg,Parker etc.

Metso: HP, GP Series of crusher bronze parts

Sandvik: H2800,H3800, H4800, H6800,H8800, etc

Symons 2inch , 3inch , 4inch, 4 1/4inch, 5 1/2inch, 7inch Standard & Shorthead.

We can guarantee you:

- OEM absolutely.

- High-quality processing for surface finish and details treatment.

- Precision dimension and skillful machining technique to satisfy clients` demand.

We mainly supply H2800~H8800 cone crusher parts:

If you are interested in the SANDVIK series cone crusher wear-resistant and spare parts or get more information, please feel free to contact me, we'll get back to you ASAP.

Specifications

High level surface finish

100% testing before its delivery.

Produced as drawings and requirement strictly.

| Number | Item description | Model |

| 442.9360-01 | Eccentric bush60.64.68.70 | H-8000 |

| 442.9358-01 | Eccentric bush36.40.44.48 | H-8000 |

| 442.9248-01 | Bottom Shell Bushing | H-8000 |

| 442.9249-01 | Ecc.wearing plate | H-8000 |

| 442.9723-01 | Main shaft step | H-8000 |

| 442.9724-01 | Piston shaft plate | H-8000 |

| 452.0805 | Eccentric bushing32.37.42.47 | H7800 |

| 452.0806 | Eccentric bushing47.52.57.62 | H7800 |

| 452.0807 | Eccentric bushing62.68.74.80 | H7800 |

| 452.0795 | Bottom Shell Bushing | H7800 |

| 452.0808-001 | Ecc.wearing plate | H7800 |

| 452.0507-001 | Main shaft step | H7800 |

| 452.0538-001 | Piston shaft plate | H7800 |

| 442.8824-01 | Eccentric bush18.20.24.28 | H-6000 |

| 442.8825-01 | Eccentric bush28 32 36 40 | H-6000 |

| 442.8826-01 | Eccentric bush40 44 48 50 | H-6000 |

| 442.8742-01 | Bottom Shell Bushing | H-6000 |

| 442.8761-01 | Eccentric wear plate | H-6000 |

| 442.8732-01 | Main shaft step | H-6000 |

| 442.8730-01 | Piston Wearing Plate | H-6000 |

| 442.8762-01 | Locating Bar | H-6000 |

| 442.8067-01 | Ecc.bushing20 25 30 36 | H-400 |

| 442.7146-01 | Bottom Shell Bushing | H-400 |

| 442.7120-01 | Main shaft step | H-400 |

| 442.7122-01 | Piston Wearing Plate | H-400 |

| 442.7107-01 | Wearing Plate | H-400 |

| 442.9406-01 | Ecc.bushing32 36 40 44 | H-4000 |

| 442.9642-01 | Ecc.bushing24 28 32 | H-4000 |

| 442.9643-01 | Ecc.bushing13 16 20 24 | H-4000 |

| 442.7110-01 | Locating Bar | H-4000 |

| 442.7923-01 | Eccentric bush16 19 22 | H-300 |

| 442.7924-01 | Eccentric bush22 25 29 | H-300 |

| 442.7925-01 | Eccentric bush29 32 34 36 | H-300 |

| 442.7927-01 | Wearing Plate | H-300 |

| 442.7935-01 | Bottom Shell Bushing | H-300 |

| 442.7895-01 | Main shaft step | H-300 |

| 442.7893-01 | Piston Wearing Plate | H-300 |

| 442.8486-01 | Eccentric bush16 20 25 30 | H-3000 |

| 442.7928-01 | Locating Bar | H-3000 |

| 442.6138-01 | Main shaft step plate | H-200 |

| 442.6139-01 | Piston Wear Plate | H-200 |

| 442.6130-01 | Wearing Plate | H-2000 |

| 442.6131-01 | Bottom Shell Bushing | H-2000 |

| 442.9657-01 | Eccentric bush13 16 18 | H-2000 |

| 442.9658-01 | Eccentric bush18 20 22 | H-2000 |

| 442.9659-01 | Eccentric bush22 25 28 | H-2000 |

| 442.9688-01 | Eccentric bush13 16 20 25 | H-2000 |

| 442.6143-01 | Locating Bar | H-2000 |

We persistently adhere to the quality principle of "implementing modern management, depending on advanced technology, basing on persistent improving, and following products with no defects", and constantly employ excellent specialists in management. We try our best to keep track with international market. Therefore, we have won the titles of "Units with Trustworthy Quality", "Units with Trust" and "3A Enterprise" for several times.

Our company has passed the evaluation of ISO9001:2008 quality certification. Thanks to our excellent production equipment, strong technology supports, fine inspection measures, and our center lab inspection (including material texture test and analysis, test for intensity and hardness), our products sell well in more than 20 provinces and cities in domestic market, and are exported to more than 10 countries and regions, such as Russia, America, Germany, Malaysia, Australia, South Africa and Italy.

Please feel free to contact us for further information.

FAQ

1.Q: What products do you offer?

A: Shenyang YYD Casting provides parts are tailored with your requirements. It ranges mainly from METSO crusher parts, especially HP series, totally replacement parts, we also welcome OEM offer from you.

2. Q: What materials can you make?

A: Tin-copper bronze, Aluminum-copper bronze, Zinc-copper bronze, Manganese-copper bronze and other material according to customer provided.

3. Q: How about the capacity? What is the max dimension?

A: The capacity is 30 tons per month. The max dimension we have casted is 5meter.

4. Q: What information should we provide to you to confirm our order of parts?

A: For standard part, you only need to provide the part number than we will define the part. But others, you should provide the technical drawings of your parts.

5. Q: What's the after-sales service if your product has quality problem?

A: First of all, you should provide us photos of the problem part and machine then our engineers will collect the necessary information to find the root cause. If it's indeed a quality problem of the product itself, we must afford compensation to you and also figure out solutions to avoid the same problem. However if it's caused by client's misconduct, we also provide the technical suggestions for our clients to solve problem better.

6. Q: Can we visit your factory?

A: Yes, of course, welcome to our factory in workday and our sales team will show you everything you want to know.

Shenyang, Liaoning, China

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

- Video

Send your inquiry to this supplier