1 / 5

Drywall Corner Bead Galvanize V Profile Rolling Machine

| Model No. : | ZT-005-166 |

|---|---|

| Brand Name : | zhongtuo |

| Type : | Cold Bending Outside Edge Channel |

Cangzhou, Hebei, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

- Video

Product description

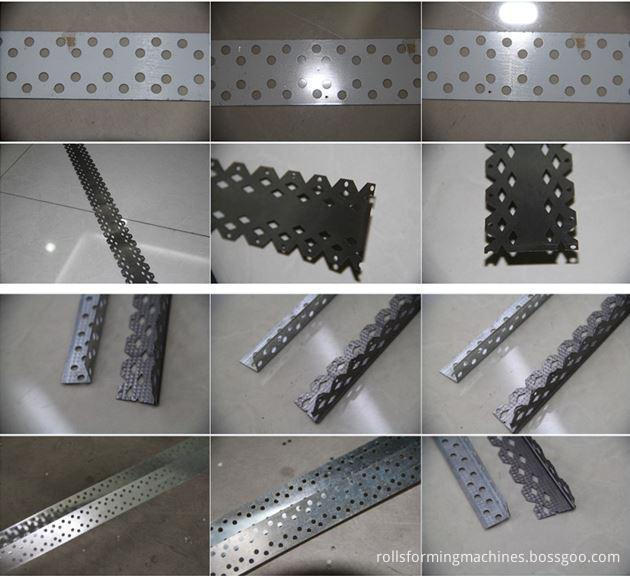

Drywall Corner Bead Galvanize V Profile Rolling Machine

Brief Introduction

Corner Bead Cold Rolled Machine is one of the main cold roll forming machine. We are the professional manufacturer of V shape machine and have many experience. The whole production line is controlled by computer. The mill can be designed for different thickness , different material and L shape profiles.

And we also have other types of light steel keel machine, such as stud,track and carrying channel, the shape can be C U L omage and so on. You can send us your idea, we will enginee machines for youself.

Process flow

Uncoiling→Punching→Roll forming→Measuring length→ Auto cutting→Products receiving

Main elements

1.Decoiler

2.Punching machine

3. main roll forming machine

4.Cutting machine (normal cutting and flying track cutting saw)(as customer`s need choose )

5.PLC control

6. Counter 1 set

7.hydraulic station

Decoiler

- Usage: It is used to support the steel coil and uncoil it in a turntable way.

- Passive uncoil pulled by roll forming system

- Loading capacity: 1.5T

- Uncoiling width: 300mm

- Inner diameter: 450-550mm

Punching machine:

Material for blade: Gcr12.

Entry leveling

This part will level coil to make sure it is neat clean and straight.

Roll forming machine

- Size: 2900х800х1400mm

- Weight : 3 tons

- Voltage:380V/50HZ3Phase(as customer`s request)

- Roller fixer : Guide column

- Frame : middle plate welded Memorial arch frame type

- Frame thickness:25mm

- Drive mode: gear

- Material of rollers: GCr12MoV

- Material of shafts: 45# steel with tempering

- Diameter of shafts: φ40mm

- Number of rollers : 8 rollers

- Main power: 3kw

Shearing system

-

Material of blades: Gcr12MoV quenched

-

Power supply : hydraulic power

-

Frame : Pillar style with rack & pinion system

-

Components: It contains one set of cutting tools, one hydraulic tank and one cutter machine.

PLC station

-

Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime.Other electric element are Delta.

-

Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety.

ZTRFM has been dedicating to roll forming technologies for over 2 decades and now boasts strong experience, capabilities, innovative thinking and roll forming expertise to provide perfect roll forming solutions to our clients. At ZTRFM, we can help build a better future for you and your customer.

1. IS AFTER SALES SERVICE AVAILABLE?

Yes, we offer 7x 24hours online support and our engineers can work oversea to help.

2. HOW CAN I GET TO YOUR FACTORY?

a. First fly to Beijing airport and then go from Beijing Nan to Cangzhou Xi (1 hour) by high speed train . Then we can pick you up at the railway station.

b. First fly to Shanghai Airport and then go from Shanghai Hongqiao to Cangzhou Xi(4.5 hours) by high speed train. Then we can pick you up at the railway station.

3. WHAT IF SOME PARTS BREAK?

We offer warranty of 12 months ,during which free spare parts are available if some parts of the machine break to be irreparable. Besides, we also offer whole life technical support which means we will still offer technical advice 1 year after your purchasing. We can discuss to help you out.

4. CAN YOU TAKE CHARGE OF TRANSPORT?

Yes, we have strong expertise in this area for years and you can trust us.

FAQ

Cangzhou, Hebei, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

- Video

Send your inquiry to this supplier