1 / 5

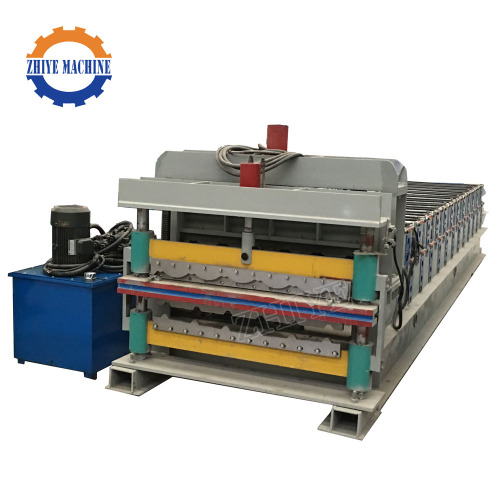

Double Layer Roofing Sheet Forming Machinery

| Model No. : | ZY |

|---|---|

| Brand Name : | ZY |

| Standard : | GOST |

Cangzhou, Hebei, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- Organization

- Service

- Trade Company

- OEM service

- Platform Certification

- Video

Product description

Double Layer Roofing Sheet Forming Machinery

products description:

This panel is set up with concrete, which has good adhesiveness. This not only can save steel moulding plate, but also can decrease the load capacity of floor decking. Therefore, steel quantity of the whole project is decreased and can save money surely.

| No. |

Double Layer Roofing Sheet Forming Machinery |

|

| 1 | Suitable to process | color steel sheet; galvanized sheet, zinc sheet |

| 2 | Width of the plate | 1250mm |

| 3 | Rollers | up layer: 12rows; down layer: 11rows |

| 4 | Dimensions | 8000*1550*1910mm |

| 5 | Power | 4+4KW |

| 6 | Thickness of the plate | 0.3-0.6mm |

| 7 | Productivity | up layer: 0-2m/min; down layer: 8-10m/min |

| 8 | Material of the cutting blade | Cr12 |

| 9 | Diameter of the roller | 70mm |

| 10 | Weight | About 3.6T |

| 11 | Voltage | 380V 50HZ 3phases |

| 12 | Control System |

PLC control |

Main Of Machine Equipement:

Manual Uncoiler:

Usage: It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand.

Loading capacity: 5T

Inner diameter: 500-508mm

Feeding Table:

Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat. Parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

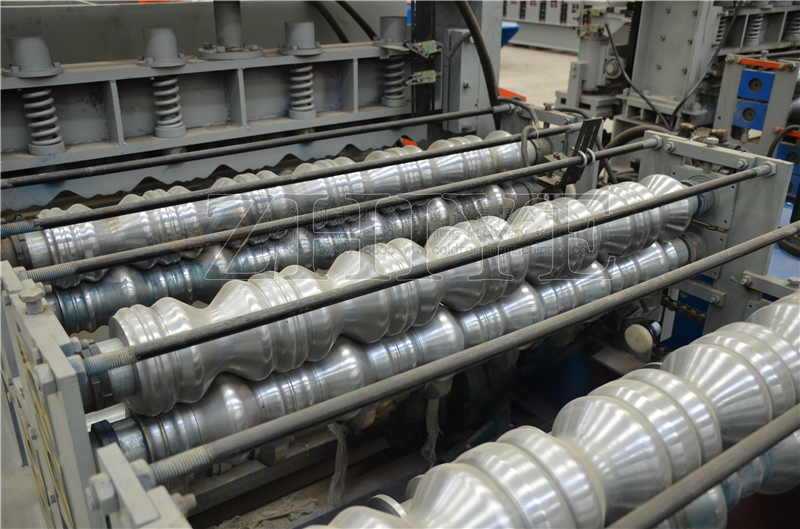

Main Roll Forming Machine:

Material of rollers: 45# steel, roller surfaces polishing, hard plating. The polished surface and the heat treatment towards the molds also can keep the molding. Plate surface smooth and not easy to be marked when it is being stamped

Hydraulic System:

Power: 11KW, Hydraulic oil:40#.

Hydraulic oil into the hydraulic oil tank, the pump drives the cutter machine to begin the cutting job.

Computer Control Cabinet: The target piece`s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use

Packaging & shipping

1.One 40ft container for loading one set machine with manual decoiler;

2.The whole Wiped Anti Rust Oil, PLC controller covered by foam film;3.Spare parts and some small parts packed in plastic tooling box;

4.All Components Fixed by steel wire with Container.

our service:

Technical Support

Fully providing technology supports both within and after the warranty period. Feed back to our customers at the first time.

Spare Parts

Promptly providing spare parts and wearing parts.

Upgrade

Improve technology and upgrade of equipments.

Cangzhou, Hebei, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- Organization

- Service

- Trade Company

- OEM service

- Platform Certification

- Video

Send your inquiry to this supplier