1 / 1

disc cutting oil centrifuges separator machine

Get Latest Price

Send Inquiry

| Model No. : | disc centrifuge |

|---|---|

| Brand Name : | Fuyi |

Liaoning Fuyi Machinery Co., Ltd.

You might also like

Product description

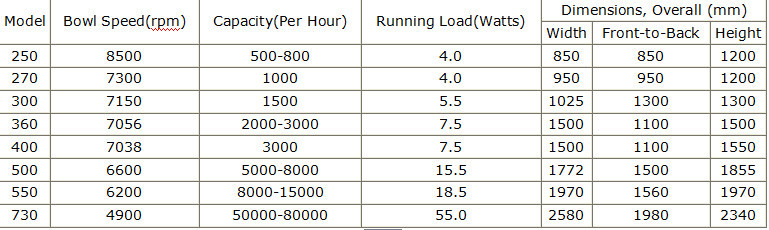

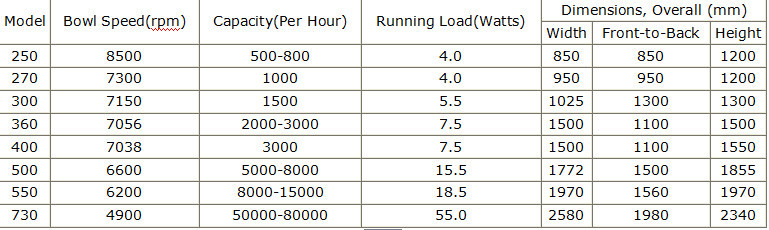

Product Description Cutting oil centrifuge machine general sepcification Disk centrifuge is high efficiency,large capacity and advanced automatic machinery which is suitable for the lower suspension liquid and proportion dissolve liquid.It is the essential machinery for pharmaceutical,chemical,bioproducts and beverage etc.The principle is based on the centrifugal forces,so it can achieve the separation purpose.The Disc Stack Centrifuge superior to the other separator or centrifuge is the advanced automatic system. Disk centrifuge can be categorize for two type based on the automatic system level: Model DHC is the fully automatic operation,discharging,running and cleaning by the PLC controller.Another model DRY is the manual discharging which is better for the lower solid content liquid material. Cutting oil centrifuge machine Main Parameter

The centrifuge is mainly parts is as photo shown . 1. Inlet and outlet device. 2. Bowl Parts 3. Centrifuge cover 4. Vertical Shaft 5. Horizontal Shaft 6. Machinery Body 7. Driving Motor

The centrifuge is mainly parts is as photo shown . 1. Inlet and outlet device. 2. Bowl Parts 3. Centrifuge cover 4. Vertical Shaft 5. Horizontal Shaft 6. Machinery Body 7. Driving Motor  The following photo shown the main pipe of the centrifuge . b. Liquid inlet Diameter Φ9 c. Clarify outlet Φ20 d. Discharge outlet Φ50 e. Operation water outlet Φ16 f. Operation water outlet Φ40 Cutting oil centrifuge machine material data Bowl body , hood and locking ring S.S304 Solids cover and frame hood S.S Frame bottom parts green cast iron , cald with In and outlet parts S.S Gasket and o-ring Nitrile rubber Cutting oil centrifuge operating principles Separation takes place inside a rotating bowl. The feed is introduced to the rotating centrifuge bowl from the top via a stationary inlet pipe (1),and is accelerated in the distributor(2),which was specially designed to ensure smooth acceleration of the feed liquid(4). Leaving the distributor, the feed enters the disc stack(3). The separation into liquid-liquid-solid takes place between the discs, with the oil phase moving through the disc stack to the centre. When it reaches the centre, it is discharged through hole (5) and ejected into the collecting frame. The water and heavy solid separated from the oil move to the periphery, and the water flows via channels in the top disc(6) to the paring chamber, where it is pumped out of the rotor by means of a built-in paring disc(7).During purification, hot water is fed into the inlet of the bowl before the process liquid is introduced. The water forms a seal around the outer edge of the top disc. The solid collect in the periphery where they are discharged intermittently via the centrifuge cyclone. The solid are discharged by means of a hydraulic system, which forces the sliding bowl bottom(8)to drop down at preset suitable intervals, thus opening the solid ports at the bowl periphery

The following photo shown the main pipe of the centrifuge . b. Liquid inlet Diameter Φ9 c. Clarify outlet Φ20 d. Discharge outlet Φ50 e. Operation water outlet Φ16 f. Operation water outlet Φ40 Cutting oil centrifuge machine material data Bowl body , hood and locking ring S.S304 Solids cover and frame hood S.S Frame bottom parts green cast iron , cald with In and outlet parts S.S Gasket and o-ring Nitrile rubber Cutting oil centrifuge operating principles Separation takes place inside a rotating bowl. The feed is introduced to the rotating centrifuge bowl from the top via a stationary inlet pipe (1),and is accelerated in the distributor(2),which was specially designed to ensure smooth acceleration of the feed liquid(4). Leaving the distributor, the feed enters the disc stack(3). The separation into liquid-liquid-solid takes place between the discs, with the oil phase moving through the disc stack to the centre. When it reaches the centre, it is discharged through hole (5) and ejected into the collecting frame. The water and heavy solid separated from the oil move to the periphery, and the water flows via channels in the top disc(6) to the paring chamber, where it is pumped out of the rotor by means of a built-in paring disc(7).During purification, hot water is fed into the inlet of the bowl before the process liquid is introduced. The water forms a seal around the outer edge of the top disc. The solid collect in the periphery where they are discharged intermittently via the centrifuge cyclone. The solid are discharged by means of a hydraulic system, which forces the sliding bowl bottom(8)to drop down at preset suitable intervals, thus opening the solid ports at the bowl periphery  Sale and After-service : 1. Only confirm with your liquid we can move into the order discussion which we will have professional liquid expert to check and test your sample than give you machinery selection . 2. We promise to give customer 24 hours after-service hot-line and we also have technician support if your country have our exclusive agent as well. Certifications

Sale and After-service : 1. Only confirm with your liquid we can move into the order discussion which we will have professional liquid expert to check and test your sample than give you machinery selection . 2. We promise to give customer 24 hours after-service hot-line and we also have technician support if your country have our exclusive agent as well. Certifications

Company Information Company information Liaoning Fuyi Machinery Co.,Ltd.was established in June 2011 formerly known as Liaoyang Sunny Pharmaceutical Machinery Co.,Ltd.which was Nationl Separation Machinery Standardization Board Member and China General Machinery Industry Association Director . Today the company is the leader in mechanical separation technology in China . Fuyi is specializing in the production and design of centrifuge , separator and filter equipment which is a high-tech enterprise combine with R&D ,Manufacturing, market prompting and sale. The company cover more than 60 acres including the advance process plant ,office ,research centre and testing lab . Fuyi’s president was the first developer and designed of Chinese First Tubular Separator who won many National Reward . The “Tubular Separator” National Standardization , currently in effect is drafted by our company . The company is certified in accordance with ISO9001:2000. Fuyi Separator provide solution to all technological problems of liquid and solid with more than 30 years experience in centrifugal separation market . For better separation result , every series products is designed and manufactured based on the different liquid material thus customer can achieve perfect separation performance . Separator and centrifuge made by Fuyi Separator are widely used in the range of areas Pharmaceutical

Company Information Company information Liaoning Fuyi Machinery Co.,Ltd.was established in June 2011 formerly known as Liaoyang Sunny Pharmaceutical Machinery Co.,Ltd.which was Nationl Separation Machinery Standardization Board Member and China General Machinery Industry Association Director . Today the company is the leader in mechanical separation technology in China . Fuyi is specializing in the production and design of centrifuge , separator and filter equipment which is a high-tech enterprise combine with R&D ,Manufacturing, market prompting and sale. The company cover more than 60 acres including the advance process plant ,office ,research centre and testing lab . Fuyi’s president was the first developer and designed of Chinese First Tubular Separator who won many National Reward . The “Tubular Separator” National Standardization , currently in effect is drafted by our company . The company is certified in accordance with ISO9001:2000. Fuyi Separator provide solution to all technological problems of liquid and solid with more than 30 years experience in centrifugal separation market . For better separation result , every series products is designed and manufactured based on the different liquid material thus customer can achieve perfect separation performance . Separator and centrifuge made by Fuyi Separator are widely used in the range of areas Pharmaceutical

Bio-tech and Medicine

Food and Dairy

Chemical

Various Oil Fuyi Separator promise to provide the most professional technology and advance quality product for global customers. We made the Standard , we beyond it.

The centrifuge is mainly parts is as photo shown . 1. Inlet and outlet device. 2. Bowl Parts 3. Centrifuge cover 4. Vertical Shaft 5. Horizontal Shaft 6. Machinery Body 7. Driving Motor

The centrifuge is mainly parts is as photo shown . 1. Inlet and outlet device. 2. Bowl Parts 3. Centrifuge cover 4. Vertical Shaft 5. Horizontal Shaft 6. Machinery Body 7. Driving Motor  The following photo shown the main pipe of the centrifuge . b. Liquid inlet Diameter Φ9 c. Clarify outlet Φ20 d. Discharge outlet Φ50 e. Operation water outlet Φ16 f. Operation water outlet Φ40 Cutting oil centrifuge machine material data Bowl body , hood and locking ring S.S304 Solids cover and frame hood S.S Frame bottom parts green cast iron , cald with In and outlet parts S.S Gasket and o-ring Nitrile rubber Cutting oil centrifuge operating principles Separation takes place inside a rotating bowl. The feed is introduced to the rotating centrifuge bowl from the top via a stationary inlet pipe (1),and is accelerated in the distributor(2),which was specially designed to ensure smooth acceleration of the feed liquid(4). Leaving the distributor, the feed enters the disc stack(3). The separation into liquid-liquid-solid takes place between the discs, with the oil phase moving through the disc stack to the centre. When it reaches the centre, it is discharged through hole (5) and ejected into the collecting frame. The water and heavy solid separated from the oil move to the periphery, and the water flows via channels in the top disc(6) to the paring chamber, where it is pumped out of the rotor by means of a built-in paring disc(7).During purification, hot water is fed into the inlet of the bowl before the process liquid is introduced. The water forms a seal around the outer edge of the top disc. The solid collect in the periphery where they are discharged intermittently via the centrifuge cyclone. The solid are discharged by means of a hydraulic system, which forces the sliding bowl bottom(8)to drop down at preset suitable intervals, thus opening the solid ports at the bowl periphery

The following photo shown the main pipe of the centrifuge . b. Liquid inlet Diameter Φ9 c. Clarify outlet Φ20 d. Discharge outlet Φ50 e. Operation water outlet Φ16 f. Operation water outlet Φ40 Cutting oil centrifuge machine material data Bowl body , hood and locking ring S.S304 Solids cover and frame hood S.S Frame bottom parts green cast iron , cald with In and outlet parts S.S Gasket and o-ring Nitrile rubber Cutting oil centrifuge operating principles Separation takes place inside a rotating bowl. The feed is introduced to the rotating centrifuge bowl from the top via a stationary inlet pipe (1),and is accelerated in the distributor(2),which was specially designed to ensure smooth acceleration of the feed liquid(4). Leaving the distributor, the feed enters the disc stack(3). The separation into liquid-liquid-solid takes place between the discs, with the oil phase moving through the disc stack to the centre. When it reaches the centre, it is discharged through hole (5) and ejected into the collecting frame. The water and heavy solid separated from the oil move to the periphery, and the water flows via channels in the top disc(6) to the paring chamber, where it is pumped out of the rotor by means of a built-in paring disc(7).During purification, hot water is fed into the inlet of the bowl before the process liquid is introduced. The water forms a seal around the outer edge of the top disc. The solid collect in the periphery where they are discharged intermittently via the centrifuge cyclone. The solid are discharged by means of a hydraulic system, which forces the sliding bowl bottom(8)to drop down at preset suitable intervals, thus opening the solid ports at the bowl periphery  Sale and After-service : 1. Only confirm with your liquid we can move into the order discussion which we will have professional liquid expert to check and test your sample than give you machinery selection . 2. We promise to give customer 24 hours after-service hot-line and we also have technician support if your country have our exclusive agent as well. Certifications

Sale and After-service : 1. Only confirm with your liquid we can move into the order discussion which we will have professional liquid expert to check and test your sample than give you machinery selection . 2. We promise to give customer 24 hours after-service hot-line and we also have technician support if your country have our exclusive agent as well. Certifications

Company Information Company information Liaoning Fuyi Machinery Co.,Ltd.was established in June 2011 formerly known as Liaoyang Sunny Pharmaceutical Machinery Co.,Ltd.which was Nationl Separation Machinery Standardization Board Member and China General Machinery Industry Association Director . Today the company is the leader in mechanical separation technology in China . Fuyi is specializing in the production and design of centrifuge , separator and filter equipment which is a high-tech enterprise combine with R&D ,Manufacturing, market prompting and sale. The company cover more than 60 acres including the advance process plant ,office ,research centre and testing lab . Fuyi’s president was the first developer and designed of Chinese First Tubular Separator who won many National Reward . The “Tubular Separator” National Standardization , currently in effect is drafted by our company . The company is certified in accordance with ISO9001:2000. Fuyi Separator provide solution to all technological problems of liquid and solid with more than 30 years experience in centrifugal separation market . For better separation result , every series products is designed and manufactured based on the different liquid material thus customer can achieve perfect separation performance . Separator and centrifuge made by Fuyi Separator are widely used in the range of areas Pharmaceutical

Company Information Company information Liaoning Fuyi Machinery Co.,Ltd.was established in June 2011 formerly known as Liaoyang Sunny Pharmaceutical Machinery Co.,Ltd.which was Nationl Separation Machinery Standardization Board Member and China General Machinery Industry Association Director . Today the company is the leader in mechanical separation technology in China . Fuyi is specializing in the production and design of centrifuge , separator and filter equipment which is a high-tech enterprise combine with R&D ,Manufacturing, market prompting and sale. The company cover more than 60 acres including the advance process plant ,office ,research centre and testing lab . Fuyi’s president was the first developer and designed of Chinese First Tubular Separator who won many National Reward . The “Tubular Separator” National Standardization , currently in effect is drafted by our company . The company is certified in accordance with ISO9001:2000. Fuyi Separator provide solution to all technological problems of liquid and solid with more than 30 years experience in centrifugal separation market . For better separation result , every series products is designed and manufactured based on the different liquid material thus customer can achieve perfect separation performance . Separator and centrifuge made by Fuyi Separator are widely used in the range of areas Pharmaceutical Bio-tech and Medicine

Food and Dairy

Chemical

Various Oil Fuyi Separator promise to provide the most professional technology and advance quality product for global customers. We made the Standard , we beyond it.

Send your inquiry to this supplier

Send Inquiry