Didtek 100% test Thermal Power Plant double eccentric rubber seated butterfly valve product range

|  |  |

| Triple Offset Butterfly Valve TBV 3001 | Cast Steel Valves CSV-1001 | Wafer Check Valve WCV-2001 |

| | | |

|  |  |

| DIN Industrial Valves DIV-4001 | Floating Ball Valve | Trunnion Ball Valve |

Product Description

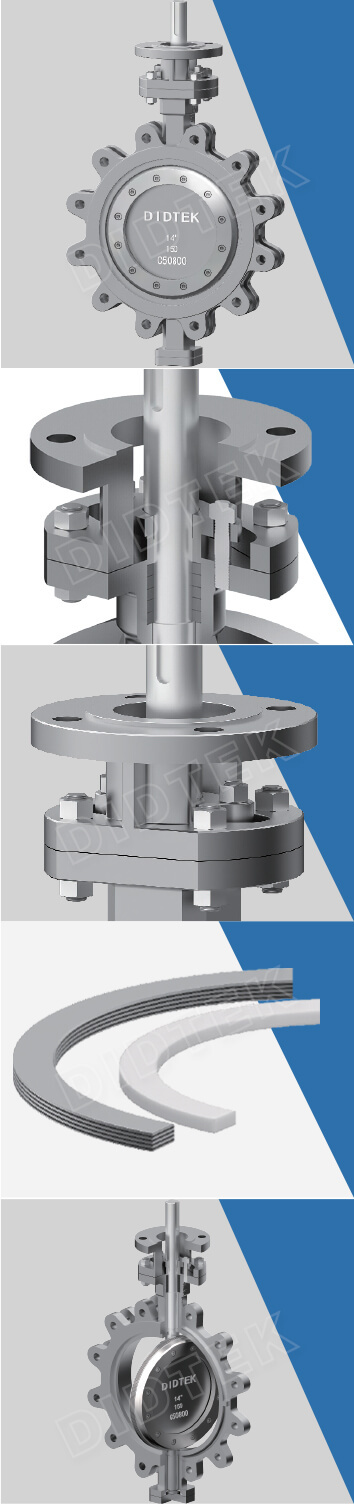

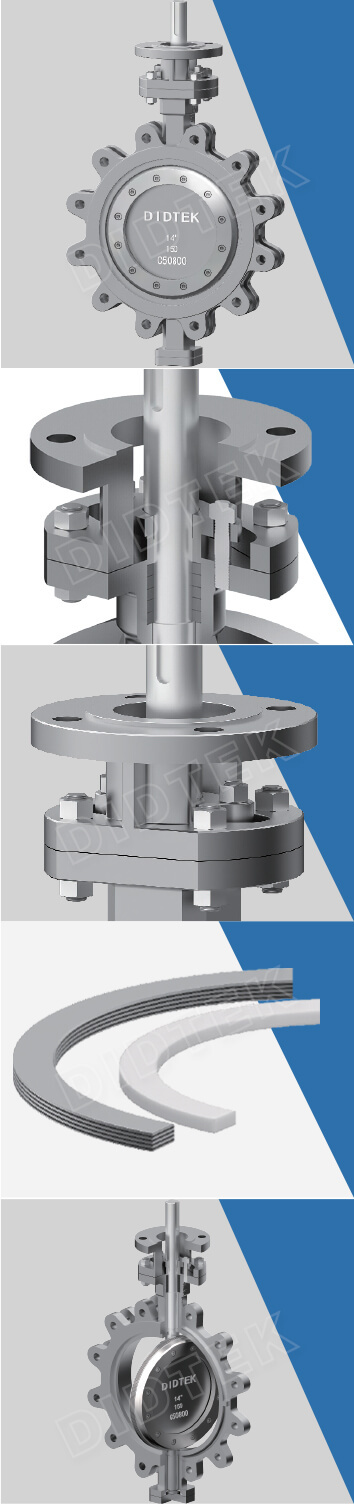

| Triple offset Lug Butterfly Valve

Figure:DIDTEKTOLBV

Applicable Standards:

- Butterfly valve design according to API 609, ASME B16.34

- Face to face ASME B16.10/API 609

- End Flanges ASME B16.5/ASME B16.47

- Butt welding ends ASME B16.25

- Inspection and testing API 598

Rating:

- ASME CL,150,300,600

Temperature Range:

- -50°C~650°C

Size Range:

- 2’’~60’’

Didtek Triple Offset Lug Butterfly Valves are manufactured to the latest editionof API Standard 609 and tested to API Standard 598. |

| Graphite Packings are intended to offer high temperature capability,good chemical resistance and markedly reduced spindle wear.By selecting or combining the many versions of Graphite Packings available. |

| Didtek Triple Offset Butterfly Valve top flanges are manufactured in compliance with ISO 5211 and will accept standard mounting yoke designs acco |

| Laminated metal+graphite seat enables smoothmating, which makes Didtek valves not only in general application but also in LNG/LPG gas applications. Each individual layer services a uniqueand independent sealing purpose. Along with Tripleoffset design, laminated seatring shows excellent performance and help provide lower operationtorque during opening and closing.

Different types of materials are selected for laminated metalplate depending on applications. |

| Design Description:

- Low friction between seat and disc of valve

- “Zero Leakage” Sealing Design

- Standard Laminated Resilient Disc Seal

to 800°F(427°C)

- One Piece Shaft

- Low torque enables the compactactuator

and a long cycle life

- Blow-out proof shaft

- Optional stem extension

- Optional locking device |

dimentions

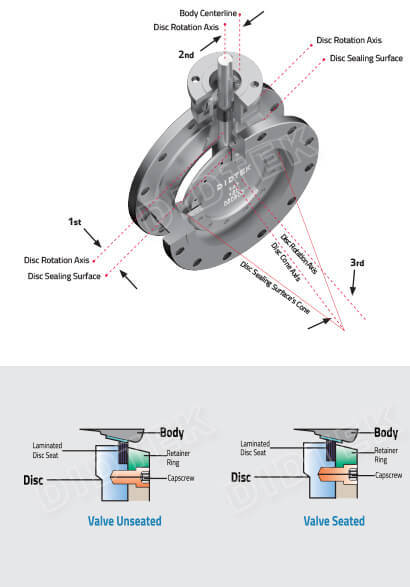

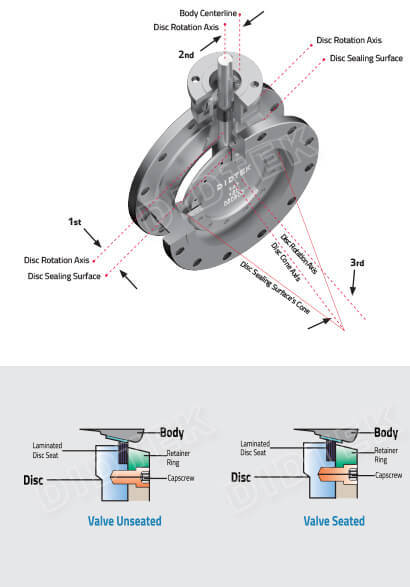

Design Characteristic of Triple Eccentric Butterfly Valve

1st offset

The rotation axis of disc is moving back from

the sealing surfaces of disc. The purpose of this offset is to have a continuous sealing surface on the disc.

2nd offset

The rotation axic of disc is relocated from the centerline of the body.The purpose of this offset is to lift the disc quickly off and away from the seat ring of the body.

3rd offset

The conical axis, which is extended from the sealing surface of disc,is inclined from the rotation axis of disc. The purpose of this offset is to eliminate friction, galling and wear of sealing surfaces

during operations and to provide bubble tight shut-off at high and cryogenic temperatures. |  |

Zero Leakage Sealing Design.

Zero leakage benefited from the unique design of the disc element and meticulously machines seat to create a perfectly matched disc and seat fit, this design also ensures that the metal seat and metal laminated sealing never be in contact with each other while the valve is cycling. Contact is made between disc seal and body only as final shut off position is reached. |

| Part Name | Carbon Steel | Alloy Steel to ASTM | Stainless Steel to ASTM |

| Body | A216 WCB+13CR | A352 LCB+304 | A217 WC1+STL | A217 WC6+STL | A217 WC9+STL | A217 C5+STL | A351 CF8 | A351 CF8M | A351 CF3 | A351 CF3M |

| Stem | A276 420 | A276 420 | A276 420 | A276 420 | A276 420 | A276 420 | A182 F304 | A182 F316 | A182 F304L | A182 F316L |

| Pin | A276 420 | A276 420 | A276 420 | A276 420 | A276 420 | A276 420 | A182 F304 | A182 F316 | A182 F304L | A182 F316L |

| Disc | A216 WCB | A352 LCB | A217 WC1 | A217 WC6 | A217 WC9 | A217 C5 | A351 CF8 | A351 CF8M | A351 CF3 | A351 CF3M |

| Multi-layer sealring | SS304+Graphite/SS316+Graphite/PTFE |

testing

Certification

Company Information

| We are experienced in valve manufacturer on Chemistry & Oil industry, our valves are qualified with the API 6D, CE97/23/EC, ISO9001,ISO14001 standards, in good quality and very competitive price. |

FAQ a) Why choose Didtek valves? Didtek Reply: Unbeatable value for money, fully certified production for all your tenders, 12 productions sites to offer you an unlimited range of valves, pipes and fittings, unlimited shipping options not to make you lose time or money, outstanding customer service: a single consultant will take care of all your requirements, making sure you get on time technical support, quotations, services and delivery. b) Where is Didtek Valve manufacturer base? Didtek Reply: The chosen location was Oubei town, a strategic position to reach a wide range of supplier of semi-finished products, foundries and raw materials and to be very close to Shanghai port. c) What's Didtek main product and market? Didtek Reply: Didtek Valve mainly manufacture Butterfly Valve, Ball Valve, DIN Industrial Valve etc, our main market is European & American Market. d) What's the application of Didtek valves? Didtek Reply: Our valves are designed and developed for petrochemical industries, fertilizers, power plants, steel plants, nuclear application, paper mills, sugar plants, oil and natural gas industries and allied process industries. e) How is the Didtek Valve production? Didtek Reply: We are equipped with CNC lathes, automatic machining centers, automatic MIG seal welding and automatic hard facing facility to reduce human error. Today equipment and technology along with a qualified training to our employees produce valves as required by international market. f) Can I be an agent for Didtek products? Didtek Reply: Yes, we're looking for the agent all over the world, please contact us for further discussion. g) Can you deliver products exclusively made for us? Didtek Reply: Yes, we have the possibility to develop products that are unique for one customer subject to individual agreements. The products may differ in appearance, technical features or packaging. Please contact us to discuss your requirements. h) How is the process of Didtek valves tested? Didtek Reply: Didtek Valves pass the test in accordance to the customer’s request, please get detailed information from our catalogue or website. contact information

....

Certification

Certification  Company Information

Company Information

....

....