1 / 1

Design and sell electromagnetic stirring

Get Latest Price

Send Inquiry

| Model No. : | Jbdz,JBDZ Series |

|---|---|

| Brand Name : | IDEA |

Shijiazhuang Idea Electric Co., Ltd.

You might also like

Product description

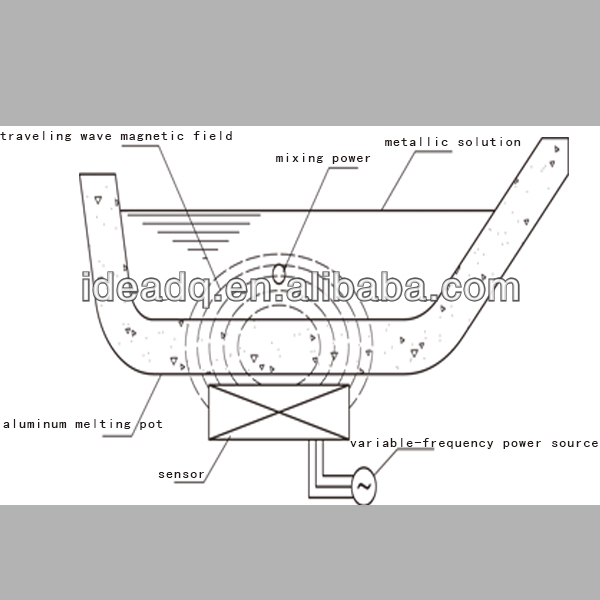

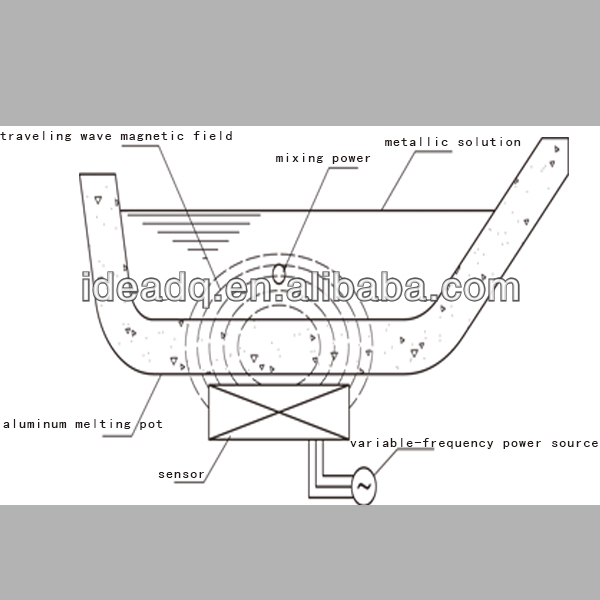

System Introduction AC Power Source using industrial-grade single-chip microcomputer control and intelligent power module as the core, make three-phase power frequency AC power frequency conversion 5-30HZ continuous adjustable ac power supply to the sensors. Sensor is mainly composed of three parts -coil, iron core and cooling, the cooling way is direct water cooling or forced air cooling, make the sensor forced cooling, to guarantee the normal work of the sensor. the coil is three-phase coil, coil respectively fixed on the iron core, when the low frequency current through the coil, produces the corresponding magnetic field. The cooling system such as using closed loop water cooling way, composed of pure water generator, cooling pump station and pipeline, the cooling system configuration water quality, water pressure, water flow, water shortage’s fault detection. "Stirring" aluminum smelting process is an important process measures. Mixing full or not directly determine the aluminum products’ quality. Mixing way has artificial stirring, gas stirring, mechanical agitation, electromagnetic stirring etc. with electromagnetic stirring because of its fully mixing, simple operation and grew in popularity.  The system composition AC Power Source: through AC-DC-AC inverters frequency conversion way to make single phase or three phase 50 hz frequency power supply converted into frequency adjustable in 5-30 hz, 0-380 - v voltage adjustable phase mutual difference 90 degrees two-phase or 120 degrees power supply to the sensor creating the magnetic field. Inductor: Sensors is energy conversion components, converts electrical energy into magnetic energy act on metal melt,reach the stirring effect. Cooling system: By forcing water cooled or air cooled make the system working in a safe environment temperature. Control and protection system: In addition to the complete system of conventional electric control, for the system to provide more complete electrical protection. The advantages of electromagnetic stirring Our company is professional producing the 2-150 tons of various kinds of specifications with aluminum melting pot electromagnetic stirring device, is the non-ferrous metal industry electromagnetic products professional manufacturers and suppliers, the product series: furnace bottom inductive electromagnetic stirring device, lateral inductive electromagnetic stirring device, renewable aluminum industry with double room furnace electromagnetic blender, etc. Electromagnetic stirring technology application can be obtained as follows effect: 1. Can make the melt alloy components uniform. General electromagnetic stirring device (no more than 20 minutes), can the whole furnace of various elements of the aluminium chemical composition of the relative deviation is less than 5%, can satisfy the almost all alloy to composition uniformity of the requirements. 2. The mixing process not destroy the oxidation layer, can reduce the melt hydrogen absorbing and oxygen, ensure the quality of the melt, and reduce the loss (relative value) 20 to 25%. 3. Can make the top and bottom of the melt temperature uniformity. General mixing ten minutes to the limit of the melt temperature can drop to less than 5 °C. So can reduce melting temperature, can improve the melt bottom alloying melting degree, in lower melting again at the same time can reduce the degree of damage. 4. In the process of aluminum ingots re-melting using electromagnetic stirring technology can shorten the time of smelting, improve work efficiency, reduce energy consumption, according to data provided by the already, can reduce energy consumption (improve efficiency) 20 to 30%. 5. No pollution aluminum melting liquid. This has the important meaning for high purity aluminium and the iron control strict alloy.6. Can reduce the labor intensity, and improve working con.

The system composition AC Power Source: through AC-DC-AC inverters frequency conversion way to make single phase or three phase 50 hz frequency power supply converted into frequency adjustable in 5-30 hz, 0-380 - v voltage adjustable phase mutual difference 90 degrees two-phase or 120 degrees power supply to the sensor creating the magnetic field. Inductor: Sensors is energy conversion components, converts electrical energy into magnetic energy act on metal melt,reach the stirring effect. Cooling system: By forcing water cooled or air cooled make the system working in a safe environment temperature. Control and protection system: In addition to the complete system of conventional electric control, for the system to provide more complete electrical protection. The advantages of electromagnetic stirring Our company is professional producing the 2-150 tons of various kinds of specifications with aluminum melting pot electromagnetic stirring device, is the non-ferrous metal industry electromagnetic products professional manufacturers and suppliers, the product series: furnace bottom inductive electromagnetic stirring device, lateral inductive electromagnetic stirring device, renewable aluminum industry with double room furnace electromagnetic blender, etc. Electromagnetic stirring technology application can be obtained as follows effect: 1. Can make the melt alloy components uniform. General electromagnetic stirring device (no more than 20 minutes), can the whole furnace of various elements of the aluminium chemical composition of the relative deviation is less than 5%, can satisfy the almost all alloy to composition uniformity of the requirements. 2. The mixing process not destroy the oxidation layer, can reduce the melt hydrogen absorbing and oxygen, ensure the quality of the melt, and reduce the loss (relative value) 20 to 25%. 3. Can make the top and bottom of the melt temperature uniformity. General mixing ten minutes to the limit of the melt temperature can drop to less than 5 °C. So can reduce melting temperature, can improve the melt bottom alloying melting degree, in lower melting again at the same time can reduce the degree of damage. 4. In the process of aluminum ingots re-melting using electromagnetic stirring technology can shorten the time of smelting, improve work efficiency, reduce energy consumption, according to data provided by the already, can reduce energy consumption (improve efficiency) 20 to 30%. 5. No pollution aluminum melting liquid. This has the important meaning for high purity aluminium and the iron control strict alloy.6. Can reduce the labor intensity, and improve working con.

The system composition AC Power Source: through AC-DC-AC inverters frequency conversion way to make single phase or three phase 50 hz frequency power supply converted into frequency adjustable in 5-30 hz, 0-380 - v voltage adjustable phase mutual difference 90 degrees two-phase or 120 degrees power supply to the sensor creating the magnetic field. Inductor: Sensors is energy conversion components, converts electrical energy into magnetic energy act on metal melt,reach the stirring effect. Cooling system: By forcing water cooled or air cooled make the system working in a safe environment temperature. Control and protection system: In addition to the complete system of conventional electric control, for the system to provide more complete electrical protection. The advantages of electromagnetic stirring Our company is professional producing the 2-150 tons of various kinds of specifications with aluminum melting pot electromagnetic stirring device, is the non-ferrous metal industry electromagnetic products professional manufacturers and suppliers, the product series: furnace bottom inductive electromagnetic stirring device, lateral inductive electromagnetic stirring device, renewable aluminum industry with double room furnace electromagnetic blender, etc. Electromagnetic stirring technology application can be obtained as follows effect: 1. Can make the melt alloy components uniform. General electromagnetic stirring device (no more than 20 minutes), can the whole furnace of various elements of the aluminium chemical composition of the relative deviation is less than 5%, can satisfy the almost all alloy to composition uniformity of the requirements. 2. The mixing process not destroy the oxidation layer, can reduce the melt hydrogen absorbing and oxygen, ensure the quality of the melt, and reduce the loss (relative value) 20 to 25%. 3. Can make the top and bottom of the melt temperature uniformity. General mixing ten minutes to the limit of the melt temperature can drop to less than 5 °C. So can reduce melting temperature, can improve the melt bottom alloying melting degree, in lower melting again at the same time can reduce the degree of damage. 4. In the process of aluminum ingots re-melting using electromagnetic stirring technology can shorten the time of smelting, improve work efficiency, reduce energy consumption, according to data provided by the already, can reduce energy consumption (improve efficiency) 20 to 30%. 5. No pollution aluminum melting liquid. This has the important meaning for high purity aluminium and the iron control strict alloy.6. Can reduce the labor intensity, and improve working con.

The system composition AC Power Source: through AC-DC-AC inverters frequency conversion way to make single phase or three phase 50 hz frequency power supply converted into frequency adjustable in 5-30 hz, 0-380 - v voltage adjustable phase mutual difference 90 degrees two-phase or 120 degrees power supply to the sensor creating the magnetic field. Inductor: Sensors is energy conversion components, converts electrical energy into magnetic energy act on metal melt,reach the stirring effect. Cooling system: By forcing water cooled or air cooled make the system working in a safe environment temperature. Control and protection system: In addition to the complete system of conventional electric control, for the system to provide more complete electrical protection. The advantages of electromagnetic stirring Our company is professional producing the 2-150 tons of various kinds of specifications with aluminum melting pot electromagnetic stirring device, is the non-ferrous metal industry electromagnetic products professional manufacturers and suppliers, the product series: furnace bottom inductive electromagnetic stirring device, lateral inductive electromagnetic stirring device, renewable aluminum industry with double room furnace electromagnetic blender, etc. Electromagnetic stirring technology application can be obtained as follows effect: 1. Can make the melt alloy components uniform. General electromagnetic stirring device (no more than 20 minutes), can the whole furnace of various elements of the aluminium chemical composition of the relative deviation is less than 5%, can satisfy the almost all alloy to composition uniformity of the requirements. 2. The mixing process not destroy the oxidation layer, can reduce the melt hydrogen absorbing and oxygen, ensure the quality of the melt, and reduce the loss (relative value) 20 to 25%. 3. Can make the top and bottom of the melt temperature uniformity. General mixing ten minutes to the limit of the melt temperature can drop to less than 5 °C. So can reduce melting temperature, can improve the melt bottom alloying melting degree, in lower melting again at the same time can reduce the degree of damage. 4. In the process of aluminum ingots re-melting using electromagnetic stirring technology can shorten the time of smelting, improve work efficiency, reduce energy consumption, according to data provided by the already, can reduce energy consumption (improve efficiency) 20 to 30%. 5. No pollution aluminum melting liquid. This has the important meaning for high purity aluminium and the iron control strict alloy.6. Can reduce the labor intensity, and improve working con.

Send your inquiry to this supplier

Send Inquiry