Video

1 / 3

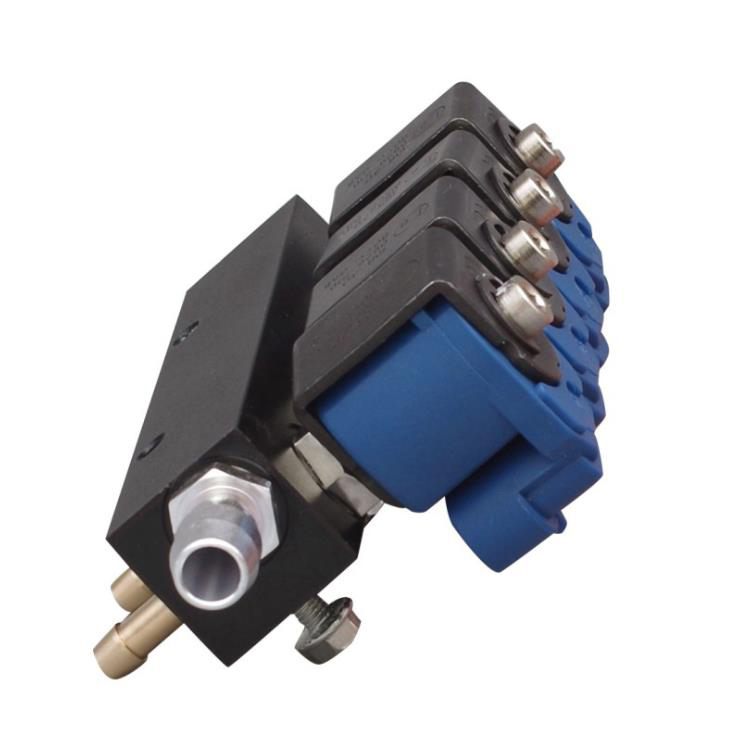

DC12V BRC Type Rail Injector Solenoid Valve Coils

| Model No. : | BB09025001 |

|---|---|

| Brand Name : | Brando |

| Voltage : | DC12V |

Ningbo, Zhejiang, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

- Video

Product description

DC12V BRC Type Rail Injector Solenoid Valve Coils

The application of the solenoid valve coil in the industry is special, mainly because the voltage used by the solenoid valve is a relatively high voltage, and the general coil cannot meet the requirements. At this time, a special material is required to meet its requirements. The solenoid valve coil is specially developed for use in this device lock, so there is a fixed customer source in the word market, which has been relatively stable in sales.

The solenoid valve coil is an important part of the solenoid valve device. Without it, the coil cannot be operated. Generally speaking, the production of the two is in one manufacturer, which is a finished product produced by the enterprise for another factory to be used. Through the use of this equipment, various substances are controlled. Because the existence of this device solves the problem that has been plaguing people, and promotes the speed of industrial development. This kind of equipment is quite flexible in control and the precision of control is also high.

Solenoid valve coils occupy this important position in the market, and there is a large demand in the society. This equipment has been sold in the market for a long time.

Technical data of DC12V BRC Type Rail Injector Solenoid Valve Coils:

Model No.

BB09025001

Normal voltage

DC12V

Normal power

DC: 48W

Insulation class

H, F

Connection type

DEUTCH

Application

BRC Type Autogas Fuel Rail Injector Solenoid Valve Coils

Weight

46.5 g

Hole size

9 mm

Height

25 mm

Width

28 mm

Overall dimension of Automotive gas Fuel Injection Solenoid Coils:

Application of 9mm CNG/LPG kits Pneumatic Solenoid Coils:

Other BRC Replacement Injector Rail Electromagnetic Coils for your reference:

What problems occur when the solenoid valve coil is in use?

Everyone knows that solenoid valves play an important role in industrial applications, and they have a long running time, and sometimes there are some problems that make the equipment not function properly. Most of this problem is caused by improper use of the solenoid valve coil.

The solenoid valve coil may not be very secure at the time of installation. During the operation of the device, the coil is in a strong operation, so that the coil will fall, the solenoid valve will not operate normally, or some may fall, and some may not. It may cause the device to work for a while and not work properly, both of which will delay the work. At this time, the operation is relatively simple, and the coil can be firmly fixed on the solenoid valve. There is also a case where the solenoid valve coil may be burnt out due to excessive voltage, and the device may not operate normally.

Therefore, when using the solenoid valve later, be sure to check the position of the solenoid valve coil and do the correct operation of the solenoid valve coil. This will ensure that the solenoid valve will not cause problems.

Steps and methods for properly installing a solenoid valve coil:

The place to pay attention when installing the solenoid valve is briefly mentioned.

1. Check if the solenoid valve and the selected parameters are the same, such as differential pressure, etc. If the error occurs, the solenoid valve coil will be burned out. Voltage fluctuations should be within the normal range and meet the rated voltage.

2. Before connecting the pipeline, flush the pipeline and remove the residual dirt in the pipeline. If there are residual stains, it will affect the normal use of the solenoid valve. To prevent this, a filter should be installed in the pipeline.

3. Install the solenoid valve coil of the solenoid valve vertically on the horizontal and ground pipes. If there is a special situation, it cannot be installed vertically. The appropriate solenoid valve should be ordered in advance, otherwise the solenoid valve will not work properly.

4. When installing, add a safety process and install a manual cutting valve to facilitate maintenance in case of failure.

5. Pay attention to the direction when installing, can not be reversed, installed in the direction indicated on the package, and can be reversed in some special cases such as vacuum.

6. If the water may be damaged by the medium, you must take appropriate protective measures or choose a solenoid valve with a waterproof hammer function.

7. The solenoid valve cannot be energized all the time, otherwise it will reduce its life. Note that normally open, normally closed solenoid valves cannot be used with care.

The above is the place to pay attention when installing the solenoid valve.

Welcome to your inquiry!

Video

Ningbo, Zhejiang, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

- Video

Send your inquiry to this supplier