1 / 5

Cut machine type Fully Automatic System step glazed tile forming machine

| Model No. : | TY roll forming mahcine |

|---|---|

| Brand Name : | Tianyu |

Product description

Cut machine type Fully Automatic System step glazed tile forming machine

Cut machine type Fully Automatic System step glazed tile forming machine

Packaging & Delivery

| Packaging Detail: | 1. Tighten to container with steel wire rope and welded machine with container by angel iron 2. Main forming machine and un-coiler is naked(If you need we can also packed with water-proof plastic) 3. PLC contral system and motor pump are packed with water proof paper coverage |

| Delivery Detail: | 15-20 days after getting advance payment |

Specifications

Roll forming machine

Material:color steel sheets

Machine speed:8-12m/min

18 years experience

CE&ISO

WE CAN DESIGN THE MACHINE AS YOUR SAMPLE OR PROFILE

|

Technical Parameters (some depend on the final design) |

||

|

1 |

Style |

sheet metal folding machines |

|

2 |

Machine dimension (mm) |

6500*1500*1200 |

|

3 |

Total wight (Kg) |

2500 |

|

4 |

Forming steps |

13 rows |

|

5 |

Forming speed (m/min) |

8-12 |

|

6 |

Hydraulic station power(Kw) |

3 |

|

7 |

Diameter of shaft (mm) |

75 |

|

8 |

Hydraulic pressure(MPa) |

18-20 |

|

9 |

Electric condition |

380V/3Phase/ 50HZ |

|

10 |

Suitable to process |

Color steel plate(G330 or G350) |

|

11 |

Decoiler max capacity (Kgs) |

10000 |

|

12 |

Control system |

PLC |

|

13 |

Raw material thickness (mm) |

0.2-0.8 |

|

14 |

Effective width(mm) |

840 |

|

15 |

Material width(mm) |

1000 |

|

16 |

Main application |

tile roof |

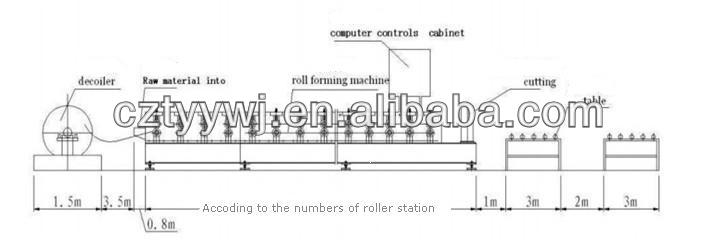

1.Process flowchart:

2.Material of main equipment:

Roller Material : High grade No.45 forged steel, with digital-controlled procession,panted with hard chrome.

Active Shaft Material : High grade No.45 carbon wrought steel,which can improve the integrated mechanic feature of the shaft

Electric Elements : PLC control panel, transducer imported from Mitsubishi,Siemens or Delta.

Cutter blade : Cr12 mould steel with quenched treatment

3.Component and function

Coil Feeding Equipment Consists of one uncoiler with capacity of 5000kgs and its base.

Guiding Equipment : Adopting guiding bar and sliding block to control the width and position of the steel sheet. The coil is guided in the correct position and passed to the roll forming equipment.

Mainframe Transmission Transfer the main motor power to the rollers through chains and sprockets, and also transfer the coil sheet.

Roll forming system : The main frame of machine is welded separately and the outside wall is connected by screw after being rotoblasted on the surface.The rollers are surface-chromeplated after being machined by the exact machine tool.

Post Cut Equipment : The length and blocks can be set by the buyer through the control panel, when reach the set length, the machine will cut the panel automatically. The cutting is finished under the power of hydraulic station which guarantees the precision of cutting.

Hydraulic Station : Supplies the initial power to the cuter through a closed oil tank. It is off without cutting, which can save the power.

PLC Control Panel : The electric controlling system of this machine consists of five parts: operating system, screen, PLC, transducer and strong electricity part. The controlling system of this machine are imported from Mitsubishi,Siemens or Delta. The system uses modularized structure and has convenient, reasonable, canonical wiring arrangement, and its maintenance is quite easy. The independent operating console facilitates the mutual dialogue between the operator and the machine. The operation is easy and steady and can be choosed operation by manual or automatically.

Supporter Table : To support the finished panels. The quantity we supply is 1 pieces with length 3000mm, it can support panels with 6000mm at normal condition.

4.Service

We provide the technical support for whole life.

Meanwhile, if any parts go broken and not artificial damage, we will send you new ones for free.

When need the technician to go abroad, we will arrange the technician.

5.Payment

T/T( 30% by T/T in advance, the rest 70% to be payed by T/T after you inspect the machine

in seller's factory before delivery ) .

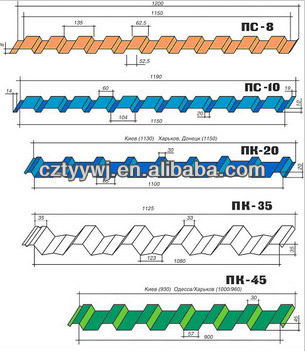

6.We can manufacture machine according to your profile

7.CE Certification

8.Contact informing

9.Production range

Semi-automtic and full-automatic roll forming machine

Corrugated roll forming machine

Double layer roll forming machine

Specialized machine for Russia

Rolling shutter door equipment

C/Z/U steel purlin equipment

Sandwich panel production line,etc

Send your inquiry to this supplier

Cut machine type Fully Automatic System step glazed tile forming machine

Cut machine type Fully Automatic System step glazed tile forming machine