1 / 6

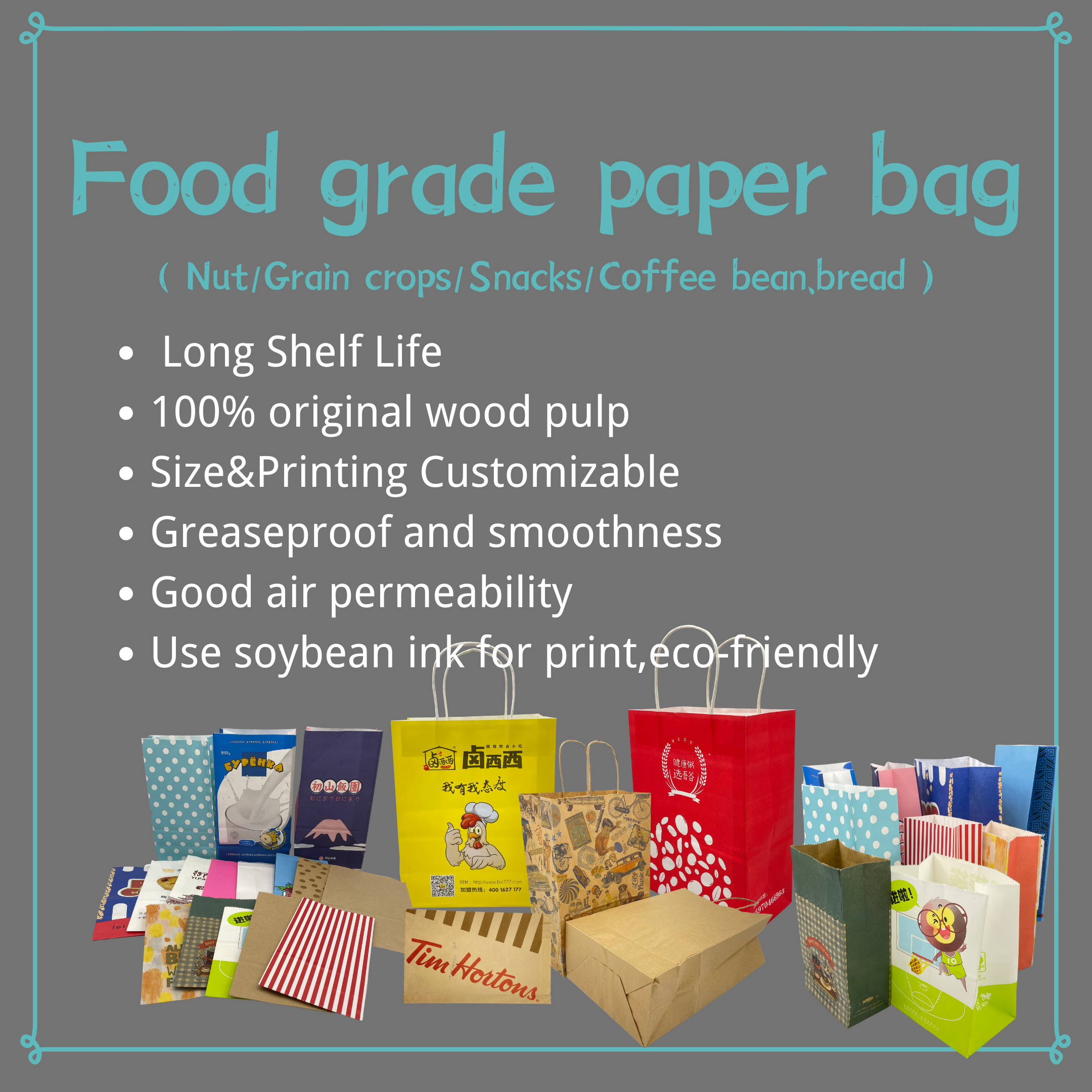

Custom size paper bag without PE lined

$0.01

~ $0.04

/ Unit

Size:

- 150*240mm

Options:

Send Inquiry

| Model No. : | paper bag without PE lined |

|---|---|

| Model Number : | PB010 |

More

2yrs

Wuxi, Jiangsu, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- SGS Certification

JIANGYIN BIOPACKAGE CO.,LTD

You might also like

Product description

The advantage of using environmentally friendly paper bags is that paper bags can effectively control the use of plastic bags. Environmentally friendly paper bags can be reused many times. The price is also relatively low, but also easy to print to promote. Paper bags of our company have high tensile strength, high toughness, usually brownish yellow color, high tear strength, rupture and dynamic strength, widely used in shopping bags, envelopes, paper bags and food packaging belts.

Semi and full automatic machines in total we have 10 production lines, monthly output is around 50-60 full containers.

We start manufacturing thermoformed pulp products from 2008 and keep promote our ability in this high competence industry, we use high quality material, try to perfect every details to make perfect products.

FAQ

Q1:Are you manufacturer or trade Company?

A1:We are a factory founded in 2008, well-known in domestic market.

We have 10 production lines for Bagasse pulp facility, 6 production lines are semi and 4 production lines are fully

automatic,monthly output is around 50 big containers. We have a mold department design and produce the molds, mold quality is the

key to bagasse pulp products.

Q2:What’s your main business activity?

A2:Paper cup, paper boxes,paper bowls and tubs, paper straws and bagasse pulp products

Q3:MOQ Quantities and Why?

A3:Usually,we request every items minimum order quantity is 50,000pcs.

Q4:What is Bagasse pulp?

A4:Bagasse is the fibrous material that remains after the juices are removed from sugarcane stalk. To make the compostable Bagasse

plates and bowls, the process starts with the repurposed Bagasse material. The material arrives at our factory as dry.Bagasse pulp

sheet, we need to break and soak it in to fiber solutions.

Q5:Why your factory quality is better and why should we choose you?

A5:First we have a high standard on ourselves and we have ambitious to be the best supplier in this industry. Luckily we have a

big public company customer from Europe, they set the quality bar very high and push us to perfect every details, this make our

products quality is one of the best on the market, also our ability from design to end products is one of the best among our peers

factories. We seek long relationship and in order to keep it long we will make our customers have comparative advantage, we try to

achieve this by providing constantly better quality products and better price.

Q6:How to develop new products?

A6:We request real samples or photos, if can not provide samples. No matter the samples is plastic or 3D print, our designer will

make new drawings based on the samples. And we shall send you drawing to do evaluation and based on your input we will do

modifications.

Q7:Lead time

A7:Generally,production leading time is 30-45 days from received the orders, if for developing new items, we need 10 days on

drawings, new mold producing time is 30days

Q8:Certifications

A8:Please email us and we will send you certifications, we have BRC, OK COMPOST, DIN, SGS, ISO....If the certifications you need

we do not have, we will apply for it.

2yrs

Wuxi, Jiangsu, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- SGS Certification

Send your inquiry to this supplier

Send Inquiry