1 / 3

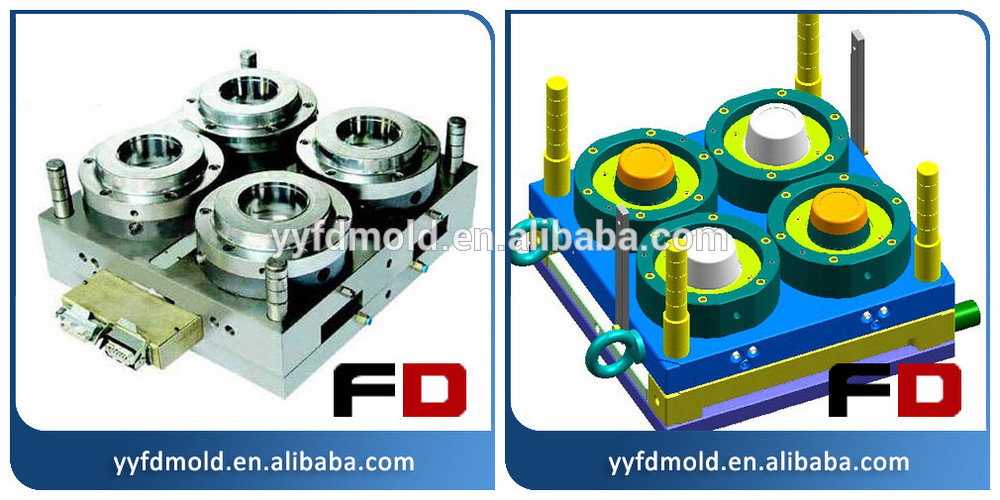

Custom Plastic Biodegradable Flower Pot Mould Manufacturer

| Model No. : | stamped mould 01010507 |

|---|---|

| Brand Name : | FDmold |

Product description

1.OEM ODM Service

2.Factory direct price

3.Custom design

4.Welding and Painting

Custom Plastic Biodegradable Flower Pot Mould Manufacturer Product Description Item: Mold/Plastic Mould /Plastic moulding /for car part/Injection plastic mold/Plastic Injection Mould /mould maker/printer mould Specifications. 1.Plastic mould making according to Sample or 3D Drawing

2.Design or Manufacture

3.Strict quality control for customer

4.Fast delivery with low cost Mould making sheet

Name | injection mould making |

mould material | 45#,P20,H13,718,2738,NAK80,S136. |

mould base | LKM,HASCO |

Cavity | 1 or more |

Runner | cold or hot runner |

Mould life | 45# :300,000-500,000shots |

P20: 500,000shots | |

718: 700,000shots | |

Design software | UG,PROE,CADetc. |

Plastic material | PP,PE,ABS,PC PET pa66 . |

Delivery time | 30-40days |

Specification | with good quality lower price |

1.Ready step | customer suppy us 3d drawing or sample .we make the injection mould drawing |

| |

2.Negotiation | the quality, price, material, delivery time, payment item, |

| |

3.Place an order | according to the confirmed plastc injetion mould drawing |

| |

4. Mould | According to customers request to build the injection mould. Before make the mould, we send mould design to customer approval first, and cusotmer pay the deposit ..before move forward to production; we will send samples to customer to confirm first. |

| |

5. Sample shoot | If the first sample come out is not satisfied customer, we will modify the mould till meet customers satisfactory. |

| |

6.Products in store | If your quantity is beyond our storage, we will provide lead time to you. |

| |

7. Delivery time | Delivery goods by sea or by air, according to customers requirement. |

1.Professional manufacturer,design,production injection mould and stamping mould quality control

2. rich export experience plastic injection mould and stamping mould

3. Reasonable price of design mould

4. Cavities: single or as per your requirements cavity

5. Treatment: S45C Pretreat>25Hrc,And Nitriding

6.Mould Steel: Cavity ,Core and slide: P20 ,2738,2136 available Moldbase :LKM available

7. Standard:DEM ,HUSKY,available

8. Design Software:UG,PRO-E,SOLIDWORKS,AUTOCAD

9. Hot runner: according to your demand

10. Life time: >300 Thousand Times

11 .Package: Plywood case, anti-rust paint

12.Transport: By Sea or Air product show

Packaging & Shipping

Packaging & Shipping | Packaging Details:

Delivery time: | CARTON OR PLALLET

Delivery goods by sea or by air, according to customers requirement. |

Our Services No matter how big you are, public or private, and in what industries or sectors you do business, we can help you work smarter and reach your goals. Have a look at the services we offer, below. 1. clear the requirement from the customers 2. Mold flow analysis report 3. Weekly report for progress. 4. ISIR (Sample Inspection Report) 5. Mold trial, process sheet 6. Pilot production 7. Mass production 8. Assembly 9. Second operation such as oil spout, silk screen, pad printing and assembling 10. Packing & Delivery arrangement after customer approve sample. Company Information Our factory integrates mold design, manufacturing, and injection molding. It is a Director Unit of Yuyao Mold Industry Association, and a key backbone enterprise in Yuyao’s plastic mold industry. FD mould engineers more than 6 years experience in design of auto moulds, precise mould, DME standard MUD molds, Hasco standard Block moulds, thin wall mould ,overmoulding mould,die casting mold and hot runner moulds. Hot runner technology, moldflow technology, gas-assistant technology are applied in our company widely, we are very familiar with well known mould standards such as HASCO,DME,MISUMI, PARKER,STAUBLI.

Our Services No matter how big you are, public or private, and in what industries or sectors you do business, we can help you work smarter and reach your goals. Have a look at the services we offer, below. 1. clear the requirement from the customers 2. Mold flow analysis report 3. Weekly report for progress. 4. ISIR (Sample Inspection Report) 5. Mold trial, process sheet 6. Pilot production 7. Mass production 8. Assembly 9. Second operation such as oil spout, silk screen, pad printing and assembling 10. Packing & Delivery arrangement after customer approve sample. Company Information Our factory integrates mold design, manufacturing, and injection molding. It is a Director Unit of Yuyao Mold Industry Association, and a key backbone enterprise in Yuyao’s plastic mold industry. FD mould engineers more than 6 years experience in design of auto moulds, precise mould, DME standard MUD molds, Hasco standard Block moulds, thin wall mould ,overmoulding mould,die casting mold and hot runner moulds. Hot runner technology, moldflow technology, gas-assistant technology are applied in our company widely, we are very familiar with well known mould standards such as HASCO,DME,MISUMI, PARKER,STAUBLI. fd mould use analysis software in every step, such as moldflow, so we can suggest customer where is the best gating and air venting configuration. We are able to simulate weld line and possible deformation, It help us to predict part outcomes strength and dimensional accuracy in advance. So we can give a advice in advance. It will help us to save a lot of developing time for a new product. Also, we are able to calculate the the injection machine parameters such as clamping force and injection pressure to help select the most appropriate injection machine for each product.. FAQ about design What is the key to making a product / mould successfully? Design is very important Is design considerate for all details? Is the design fully satisfied all requirements of customer? These are key factors for a successful mould /product design . we will check customer data/specification carefully, send a report of advice and manufacture ability let customer confirmation After got the confirmation, we start designing mold construction and full 3D design. fd mould always keep in touch with customer in every step, to ensure that all the details are in accordance with customer request.

FD mould engineers more than 6 years experience in design of auto moulds, precise mould, DME standard MUD molds, Hasco standard Block moulds, thin wall mould ,overmoulding mould,die casting mold and hot runner moulds. Hot runner technology, moldflow technology, gas-assistant technology are applied in our company widely, we are very familiar with well known mould standards such as HASCO,DME,MISUMI, PARKER,STAUBLI.

fd mould use analysis software in every step, such as moldflow, so we can suggest customer where is the best gating and air venting configuration. We are able to simulate weld line and possible deformation, It help us to predict part outcomes strength and dimensional accuracy in advance. So we can give a advice in advance. It will help us to save a lot of developing time for a new product. Also, we are able to calculate the the injection machine parameters such as clamping force and injection pressure to help select the most appropriate injection machine for each product.. Our advantage : We should save you money through intelligent tooling design and efficient production runs. We have advanced CMM Machine, CNC Machine, EDM Machine, Wire-Cutting and other normal machine, the injection machine from 20 ton to 1000 Ton. We can injection almost any kind of plastics such as ABS, PC, PBT, ABS-PC, PP, PMMA, PE, nylon, etc. The steel we use for manufacturing moulds are P-20, H-13(fully hardened mould with HRC 52-54, 420 SS (Stainless Steel),ETC or as specified by the customers.

Send your inquiry to this supplier