1 / 6

Custom Diecast Cast Service Aluminum Die Casting Parts

$1.30

≥200 Others

$1.20

≥1000 Others

$1.00

≥3000 Others

Send Inquiry

| Brand Name : | ZONGCHI |

|---|

More

2yrs

Ningbo, Zhejiang, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

Ningbo Zongchi Machinery Technology Co., LTD

You might also like

Product description

Product Description

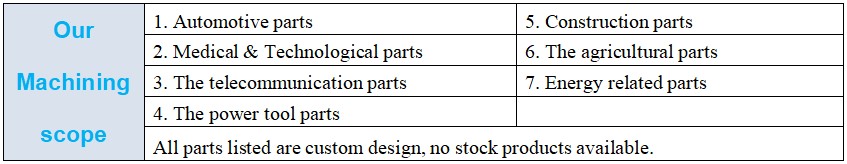

|

Product Name

|

Custom Alloy Suppliers Companies Diecast Cast Service Aluminum Die Casting Parts

|

|

|

|

|||

|

Material

|

ADC12,A380,AlSi12,A356,A360 ,ZAMAK 3, ZAMAK5,ZA8,ZA3,,ZL101,102,114 or as per customer's needs

|

|

|

|

|||

|

Surface Treatment

|

Powder Coating, Anodizing, Brushing, Polishing, Electric-plating, Pvd Coating, Hot Dip Galvanizing, E-coating, Tin Plating, Nickel Plating, Chrome Plating, Dacromet, Enamel Coating etc.

|

|

|

|

|||

|

Size & Weight

|

As per customer's drawings

|

|

|

|

|||

|

Casting roughness

|

Ra1.6-3.2

|

|

|

|

|||

|

Casting tolerance

|

+/-0.01mm ~ +/-0.05mm

|

|

|

|

|||

|

Our engineering and mould-making technology includes:

|

1. Pro/ENGINEER (3D Modeling)

2. SolidWorks (3D Modeling)

3. AutoCAD (2D Modeling)

4. MoldFlow Mold Advisor (Plastic flow/deform simulation)

5. MasterCAM (CNC Programming)

6. Unigraphics (CNC Programming)

7. CNC Machining Centers

8. CNC EDM's (Electro-Discharge Machining)

9. Wire-Cut Machines

|

|

|

|

|||

|

File format

|

Solidworks, Pro/Engineer, Auto CAD, PDF, JPG, DXF, IGS, STEP

|

|

|

|

|||

|

Testing Equipments

|

Spectrometer ,CMM, X ray,Metallographic microscope, Hydrogen tester,Electric tensile testing machine ,Digital height meter,Digital hydraumatic testing machine ,Hardness tester, Roughness tester/Profile Tester ,Gas power meter,Cleanliness detector machine and so on.

|

|

|

|

|||

|

Quality Assurance

|

IATF16949,ISO9001,100% inspection before shipping

|

|

|

|

|||

|

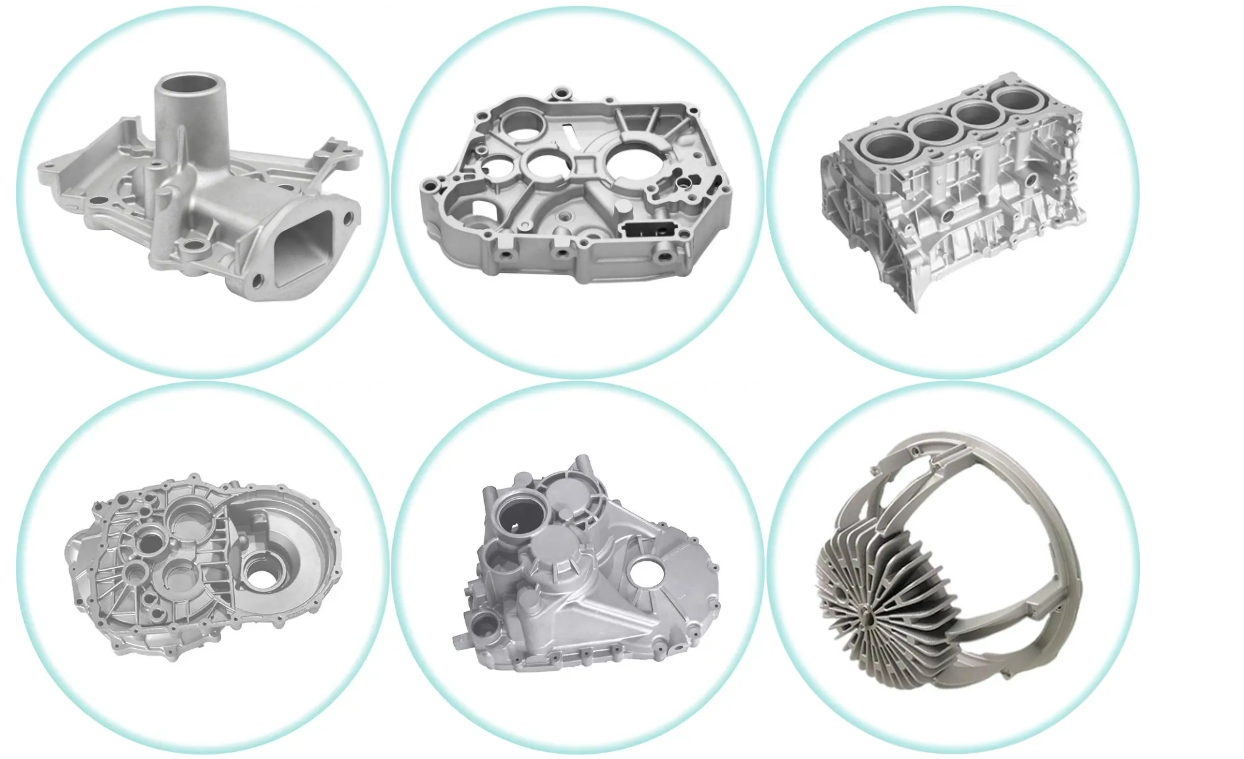

Application

|

Aerospace, Automotive, Agriculture, Construction, Electrical, Electronic, Home Appliance, Medical, Marine, Machinery, Furniture,Food, Lighting, Telecommunication, etc

|

|

|

|

|||

|

ODM &OEM

|

Acceptable

|

|

|

|

|||

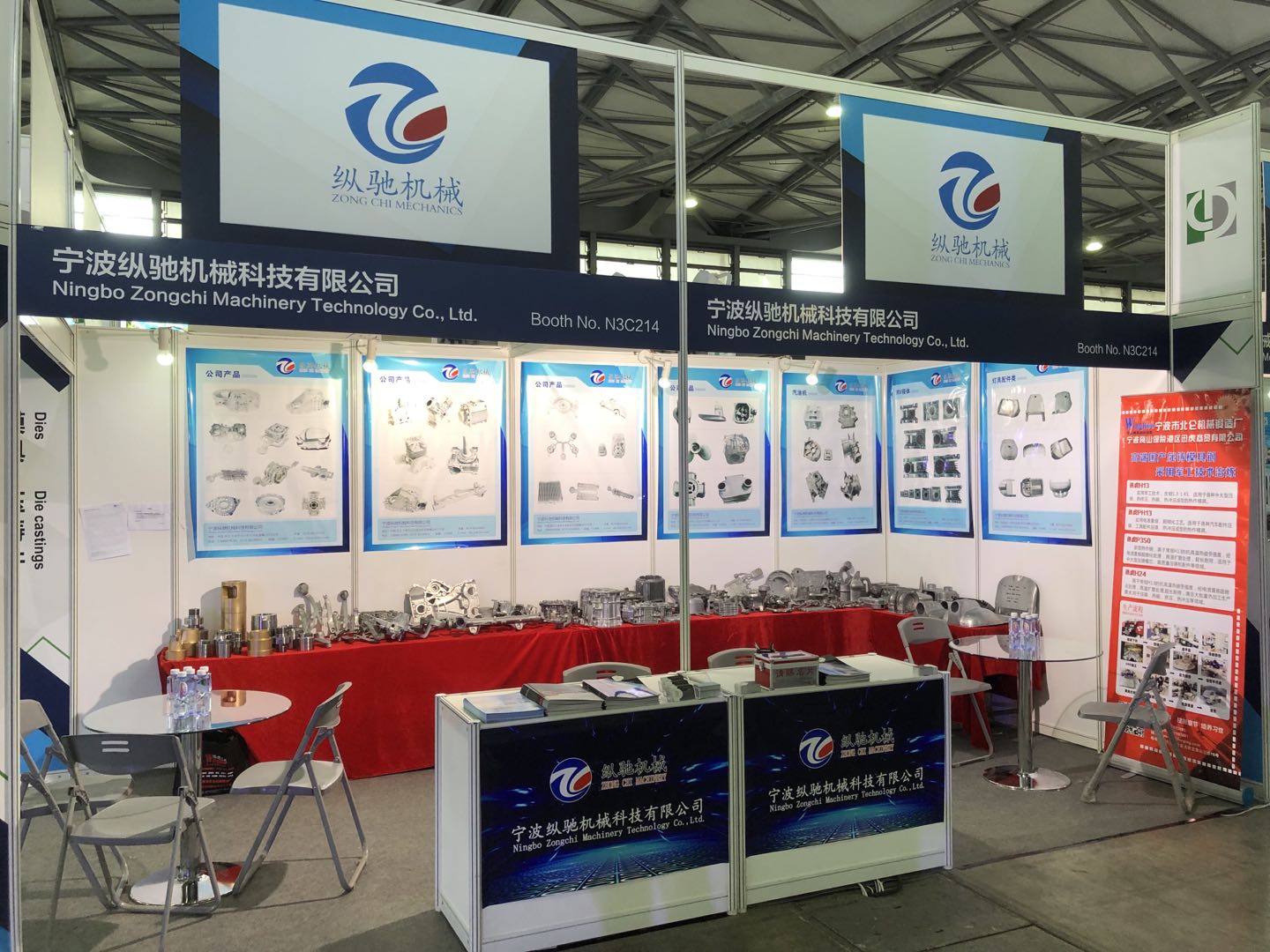

Company Profile

Ningbo Zongchi Machinery Technology CO., Ltd,founded in 2006,which has specialized in Tooling Design & Manufacture, Aluminum /Zinc/ Magnesium Die Casting Parts,Plastic Parts , High Precision CNC machining for almost 16 years.Our products are widely used in Auto Parts, Motorcycle parts,ATM&Vending machine parts,Electric valve housing parts,Power tools parts ,Communication equipment parts,Lighting parts, Agricultural and textile machinery parts and so on,the product quality and service have been highly praised by customers now.The factory is located in Ningbo Beilun,which has the reputation of "hometown of Chinese die casting mould" , the geographical position is superior, the east is near to the buddhist resort”Putuo Mountain”,the Hangzhou-Ningbo expressway in the west, 329 state road is in the south and north of Beilun Port, traffic is very convenient.The company covers an area of 12,000 square meters, a building area of 15,000 square meters. After several years of steady development, the company currently has more than 130 employees, including about 20 professional management and technical research personnel.

Zongchi has passed IATF16949 & ISO9001 certification,we has the gauge testing capability of all the products structural size, physical and mechanical properties, surface quality and so on.

The laboratory is equipped with X-ray detector, CMM, projector and spectrum analyzer, metallographic detector, tensile strength testing machine, chromophotometer, film thickness tester, hardness tester, salt spray testing machine and other high-end testing equipment, and has the CMK, PPK, CPK and other index statistics and analysis capabilities.

The company adopts CAD/UG/CAM/CAE advanced design software, with precision CNC center, more than 100 sets of equipment such as machining center, CNC EDM, wire cutting, die casting machine, injection molding machine, etc.

As an one-stop manufacturer, ZONGCHI also offers you complete and through assembly and testing of products.Whether you’re interested in any special Casting parts ,CNC Machining parts ,Hardware fittings,Plastic parts or simply want to prototype a new part, you’ll get a satisfied full service experience available in our factory.

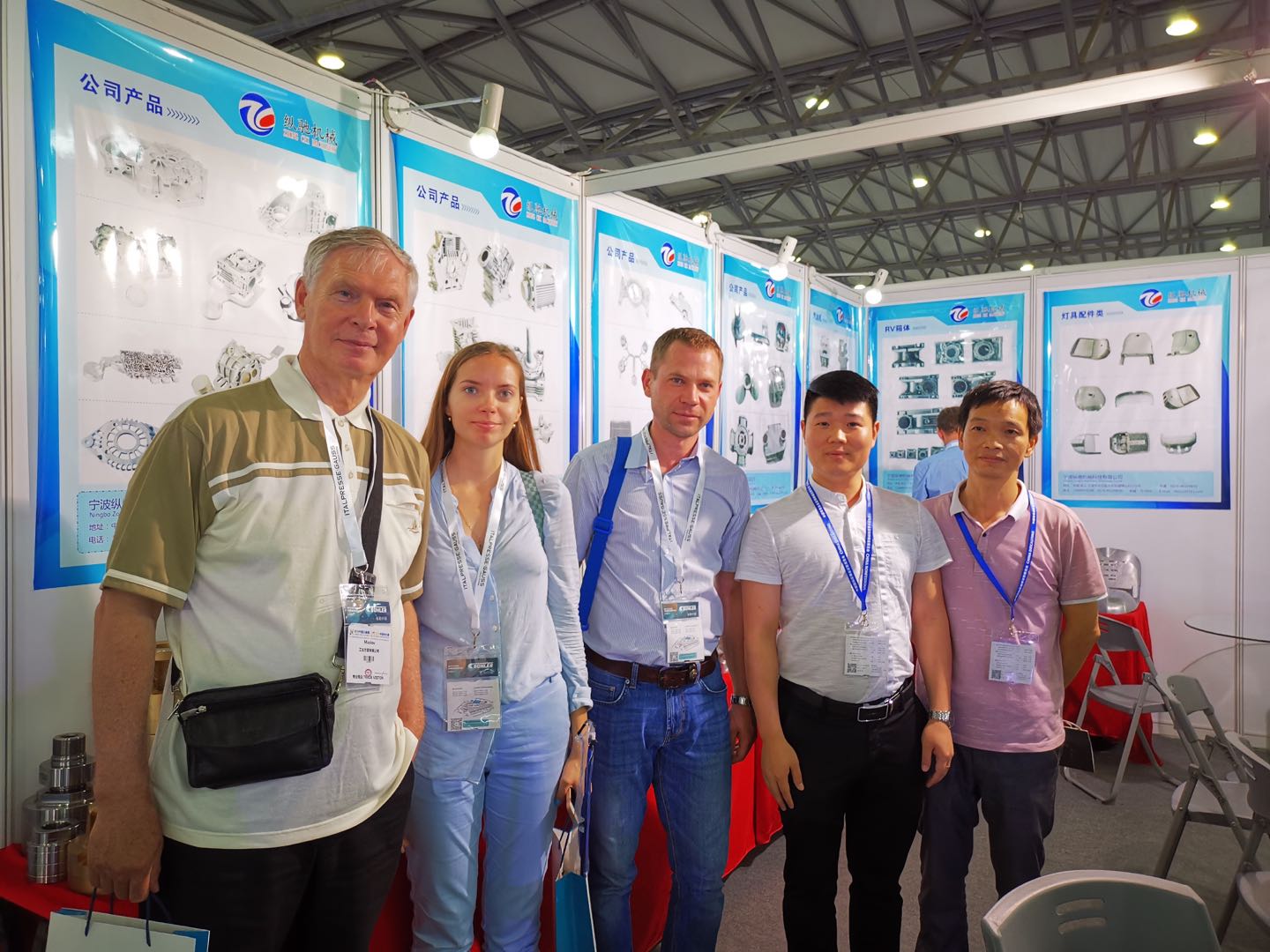

Now the company is in rapid development stage, sincerely welcome foreign customers and friends to visit and win-win cooperation, join hands in creating a better tomorrow.

Zongchi has passed IATF16949 & ISO9001 certification,we has the gauge testing capability of all the products structural size, physical and mechanical properties, surface quality and so on.

The laboratory is equipped with X-ray detector, CMM, projector and spectrum analyzer, metallographic detector, tensile strength testing machine, chromophotometer, film thickness tester, hardness tester, salt spray testing machine and other high-end testing equipment, and has the CMK, PPK, CPK and other index statistics and analysis capabilities.

The company adopts CAD/UG/CAM/CAE advanced design software, with precision CNC center, more than 100 sets of equipment such as machining center, CNC EDM, wire cutting, die casting machine, injection molding machine, etc.

As an one-stop manufacturer, ZONGCHI also offers you complete and through assembly and testing of products.Whether you’re interested in any special Casting parts ,CNC Machining parts ,Hardware fittings,Plastic parts or simply want to prototype a new part, you’ll get a satisfied full service experience available in our factory.

Now the company is in rapid development stage, sincerely welcome foreign customers and friends to visit and win-win cooperation, join hands in creating a better tomorrow.

Production Process

Related Products

Packing & Delivery

Standard export package(poly bag/air bubble bag + carton + pallet ) or as per customer's needs. Shipping Details : by air (DHL,UPS,TNT,Fedex etc) or by sea.

Certifications

Exhibitions & teams

FAQ

1. Q: Are you trading company or manufacturer ?

A:We are a professional die casting manufacturer with over 16 years experience in the design and production of

2. Q: How long is your delivery time?

A:Mold leadtime: 15-40 days. It depends on the structure of the mold.

Batch production leadtime: If the goods are in stock, it 's 5-10 days; If the goods aren't in stock, it's according to

A:We are a professional die casting manufacturer with over 16 years experience in the design and production of

mechanical parts.

2. Q: How long is your delivery time?

A:Mold leadtime: 15-40 days. It depends on the structure of the mold.

Batch production leadtime: If the goods are in stock, it 's 5-10 days; If the goods aren't in stock, it's according to

quantity.

3. Q: Do you provide samples ? Is it free or extra ?

A:If you need, we are glad to offer you samples for free, but the new clients are expected to pay the courier cost, and the

3. Q: Do you provide samples ? Is it free or extra ?

A:If you need, we are glad to offer you samples for free, but the new clients are expected to pay the courier cost, and the

charge will be deducted from the payment for formal order.

4. Q:Can you make Die Casting Parts according to our drawings or samples ?

A:Yes, we can develop and manufacture according to your 2D, 3D drawings or samples.

5. Q:What's your quality control device in house?

A:We have an internal spectrometer monitoring system, tensile testing machine to control the mechanical properties,

6. Q: What is your terms of payment ?

7. Q: What services can we provide?

A: Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

9. Q: Why us ?

A: Development with advanced machining equipment

Strict quality management system

Excellent trade service capability

Covering our service by the functionalities of design and production.

A1:We are factory ,we could give you ,

Superior Quality

Competitive Price

Shortest leadtime

Excellent Service

4. Q:Can you make Die Casting Parts according to our drawings or samples ?

A:Yes, we can develop and manufacture according to your 2D, 3D drawings or samples.

5. Q:What's your quality control device in house?

A:We have an internal spectrometer monitoring system, tensile testing machine to control the mechanical properties,

projectors,CMM, hardness testing instruments and other test instruments to control the casting detection under the

surface of cast aluminum parts.

6. Q: What is your terms of payment ?

A:Mold:50% mould cost paid to start the mould, 50% mould cost paid after the sample approved. Batch production: 30%

deposit,the balance will be paid before delivery.

A1: The payment terms can be negoniated or as per customer's needs .7. Q: What services can we provide?

A: Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

8. Q: Our advantages

A: 24 hours online service.9. Q: Why us ?

A: Development with advanced machining equipment

Strict quality management system

Excellent trade service capability

Covering our service by the functionalities of design and production.

A1:We are factory ,we could give you ,

Superior Quality

Competitive Price

Shortest leadtime

Excellent Service

2yrs

Ningbo, Zhejiang, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

Send your inquiry to this supplier

Send Inquiry