1 / 3

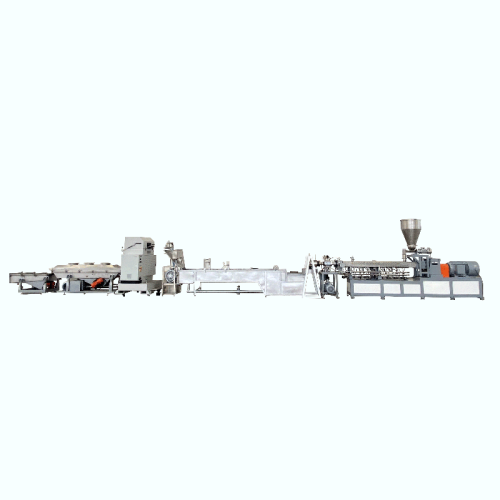

Corn Starch Biodegradable Compounds Twin Screw Extruder

| Model No. : | PSHJ-50 |

|---|---|

| Brand Name : | XINDA |

| Raw Material : | PP |

Wuxi, Jiangsu, China

- Manufacturer

- Service

- OEM service

- Platform Certification

- SGS Certification

- Online Expo

- Video

Product description

High Quality Twin Screw Extruder For Fiber Glass Reinforcement Pelletizing Line

The barrel of Extruder Line Masterbatch can be opened in minutes. This makes product changeover, maintenance and research fast and easy. Both screws and barrels are designed using the building block principle. The screw configuration, barrel setup, feeding and venting, screen changing, way of pelletizing and process requirements, in consideration of the machine's versatility in other general applications.

Application for Twin Screw Extruder:

--Various plastic inorganic filler, polymer blending (plastic alloy), plastic coloring, ect

--Various engineering plastic reinforcement of glass fiber, flame-retartant pellets

--Various antibacterial, insulated, toughening materials for specific uses

--Light/biology degradable film materials, amylum degradable plastics and multi-functional anti-fog film materials, etc.

--Specific material for automobiles and household appliance and cable materials, etc

--Themoplastic elastomers, such as TPR, TPE, and SBS, etc

--Regenerate pellets for PVC airproof pieces, thermo-soluble glue, etc

Model Reference

|

Model

|

PSHJ-20

|

PSHJ-35

|

PSHJ-50

|

PSHJ-65

|

PSHJ-75

|

PSHJ-127

|

|

Screw Diameter:

MM |

21.7

|

35.6

|

50.5

|

62.4

|

71

|

126

|

|

Central Distance

|

18

|

30

|

42

|

52

|

60

|

102

|

|

Length Diameter Ratio

|

28-52

|

28-52

|

28-52

|

28-52

|

28-52

|

28-52

|

|

Main Motor Power

|

4-5.5

|

22-45

|

75-110

|

110-185

|

160-280

|

90-160

|

|

Max.Screw Speed:

RPM |

600

|

600

|

600

|

600

|

600

|

600

|

|

Output Torque per Shaft:N.m

|

32-43

|

175-358

|

597-875

|

875-1472

|

1273-2228

|

850-1528

|

|

Reference Output: KG/HOUR

|

5-20

|

20-80

|

80-200

|

150-350

|

300-600

|

800-1500

|

|

Model

|

C-PSHJ-35

|

C-PSHJ-50

|

C-PSHJ-65

|

C-PSHJ-75

|

C-PSHJ-127

|

|

Screw Diameter:

MM |

35.6

|

50.5

|

62.4

|

71

|

126

|

|

Central Distance

|

30

|

42

|

52

|

60

|

102

|

|

Length Diameter Ratio

|

28-52

|

28-52

|

28-52

|

28-52

|

13-18

|

|

Main Motor Power

|

22-45

|

75-132

|

110-250

|

160-355

|

90-160

|

|

Max.Screw Speed:

RPM |

800

|

800

|

800

|

800

|

500

|

|

Output Torque per Shaft:N.m

|

131-269

|

448-788

|

657-1492

|

955-2119

|

850-1528

|

|

Reference Output: KG/HOUR

|

150-300

|

200-500

|

400-800

|

500-100

|

800-1500

|

Product Description

About factory

Certification

Customers list

Exhibition and Worldwidely

Wuxi, Jiangsu, China

- Manufacturer

- Service

- OEM service

- Platform Certification

- SGS Certification

- Online Expo

- Video

Send your inquiry to this supplier