Video

1 / 4

Conventional Rotator Welding Rotator Tank Rotator

Options:

- GLHK Welding Rotator

| Model No. : | GLHK Conventional Rotator |

|---|---|

| Brand Name : | Zhouxiang |

| status : | New |

Wuxi, Jiangsu, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- SGS Certification

Product description

Conventional Welding Rotator

Conventional Welding Rotator Introduction:

Conventional welding rotator is widely used for pipe, boilers, pressure vessel, oil tank and other cylinder’s assembling, burnishing and welding. The machine can assort all kinds of auto welding, manual welding .improving welding quality ,lessening welding labor and improve productivity.

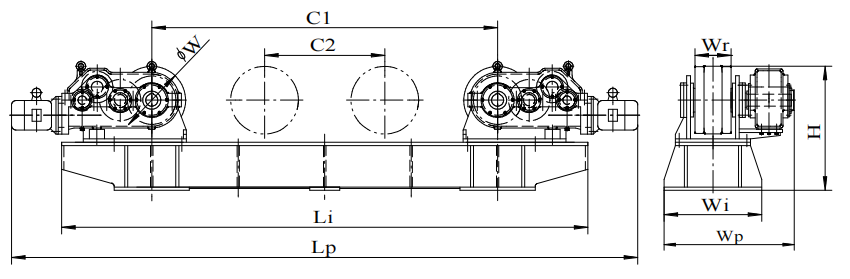

A set of conventional welding rotator including one power rotator, one idle rotator and electric control. The wheels center to center distance will be adjusted by workers. It is mainly used to cooperate with the submerged arc automatic welding machine for longitudinal and circumferential seam welding.

|

Model

|

Max Load

Cap.

|

Tanks Dia.

Range

|

Motor Power

|

Rotate

Speed

|

Wheels Center

Distance

|

Wheels

Diameter & Width

|

Roll Dimensions

|

|

|

C1-C2

|

ΦW*Wr

|

Lp * Wp * H

|

Li * Wi * H

|

|||||

|

|

Ton

|

M

|

Kw

|

M/h

|

m

|

mm

|

||

|

GLHK-3

|

3

|

0.25-1.8

|

2*0.25

|

6-60

VFD Adjust

|

0.90-0.25

|

200*140

|

1673*485*385

|

1260*380*385

|

|

GLHK-5

|

5

|

0.32-2.3

|

2*0.37

|

1.10-0.40

|

250*140

|

1894*529*475

|

1600*436*475

|

|

|

GLHK-10

|

10

|

0.32-2.8

|

2*0.55

|

1.40-0.45

|

300*170

|

2479*605*534

|

1840*486*534

|

|

|

GLHK-20

|

20

|

0.5-3.5

|

2*1.1

|

1.75-0.50

|

350*180

|

2988*661*649

|

2450*514*649

|

|

|

GLHK-40

|

40

|

0.6-4.2

|

2*1.5

|

2.00-0.70

|

400*200

|

3489*724*715

|

2980*600*715

|

|

|

GLHK-60

|

60

|

0.75-4.8

|

2*2.2

|

2.55-0.76

|

450*240

|

4398*861*825

|

3500*700*825

|

|

|

GLHK-80

|

80

|

0.85-5

|

2*3

|

2.50-1.00

|

500*260

|

4365*900*890

|

3700*700*890

|

|

|

GLHK-100

|

100

|

1-5.5

|

2*3

|

2.80-1.00

|

500*300

|

4665*960*955

|

4000*760*955

|

|

|

GLHK-160

|

160

|

1.1-6

|

2*4

|

3.15-1.10

|

650*250

|

5528*1052*1140

|

4550*780*1140

|

|

|

GLHK-250

|

250

|

1.2-7

|

2*5.5

|

3.50-1.10

|

700*280

|

5168*1115*1245

|

4930*820*1245

|

|

|

GLHK-500

|

500

|

1.5-8

|

2*7.5

|

3.75-1.25

|

850*350

|

5824*1331*1565

|

5500*960*1565

|

|

|

GLHK-630

|

630

|

1.5-9

|

2*11

|

4.40-1.20

|

900*380

|

6805*1493*1475

|

6500*1110*1475

|

|

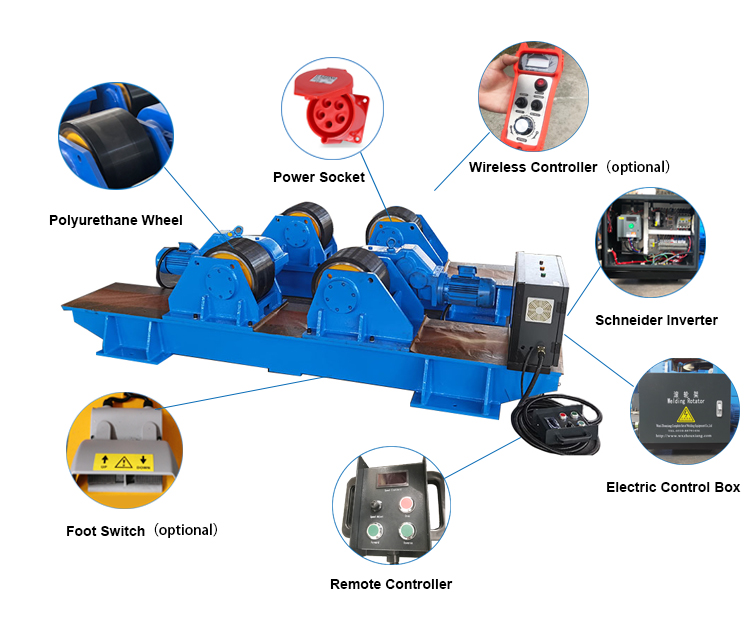

Conventional Welding Rotator Details:

Rotator structure is firm and durable: The structural components of the rotator has carried with annealing treatment, then reprocessing after welding, which can ensure the long-term usage and service time.

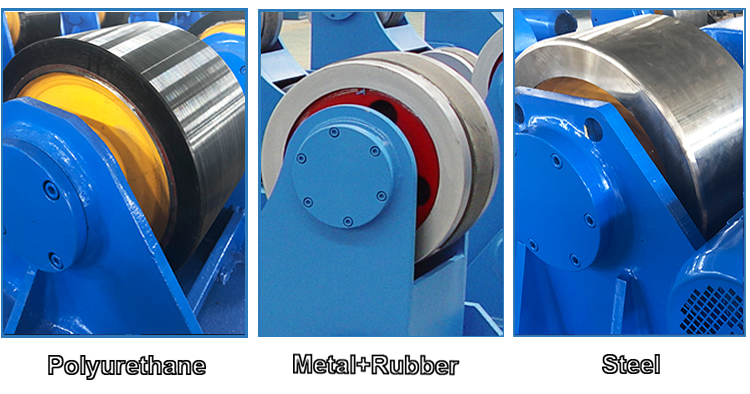

Roller’s material is optional: The rollers are generally made of full PU rollers, which are wear-resistant, acid-resistant, and

Remote control box is easy to operate:All operations of the equipment can be concentrated on the remote control box, which is anti-collision and can be hung.

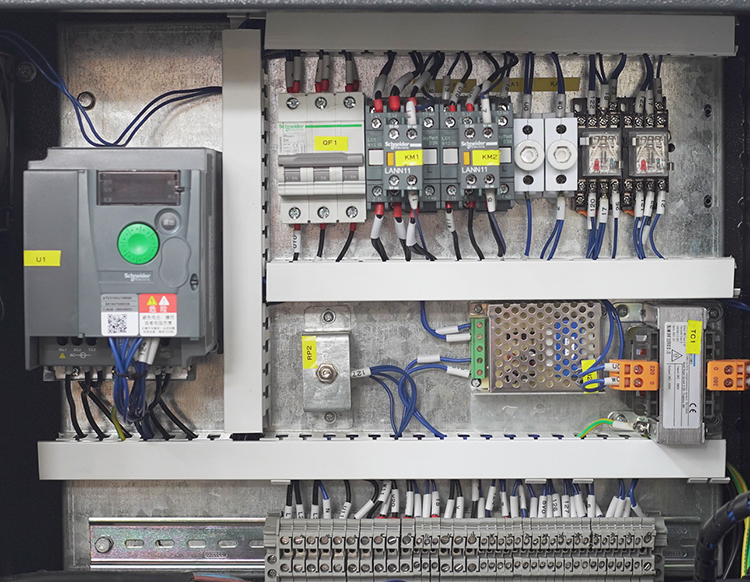

Roller speed stepless variable frequency speed control:We use Schneider inverter stepless speed regulation,which has wide speed adjusting range.

What is “Automatic Welding Center”?

Automatic welding center refers to a key welding process in similar welding components as the core, and the components required to complete the welding process are arranged and combined according to the typical process procedures of the welding process, forming the completion of the welding process. workplace. Welding center is also called welding workstation.

The welding center consists of the following parts:

1. Welding power source: welding machine, machine head, wire feeder;

2. Welding machinery and equipment: such as workpiece roller frame, welding positioner, welding manipulator;

3. Welding auxiliary machinery: such as flux pads, flux conveying and recycling devices;

4. Workpiece transmission device: including feeding, conveying and unloading mechanisms;

5. Automatic welding seam tracking and automatic adjustment device for welding wire dry elongation;

6. Integrated electrical control system.

Video

Wuxi, Jiangsu, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- SGS Certification

Send your inquiry to this supplier