1 / 1

Complete pasteurized uht milk processing machinery system price

Get Latest Price

Send Inquiry

| Model No. : | milk processing machinery, JM-MILK55 |

|---|---|

| Brand Name : | JOYLONG |

Shanghai Jinglong International Trade Co.,Ltd.

You might also like

Product description

Specifications complete pasteurized uht milk processing machinery

1.Longlife service

2.CE,ISO certificate

3.High quality

4. Good service

Complete pasteurized uht milk processing machinery system Description:

Description:

With a product that can be stored for long periods without spoiling and with no need for refrigeration, there are many advantages for both the producer, the retailer and the consumer. This includes expensive products such as cream, desserts and sauces.

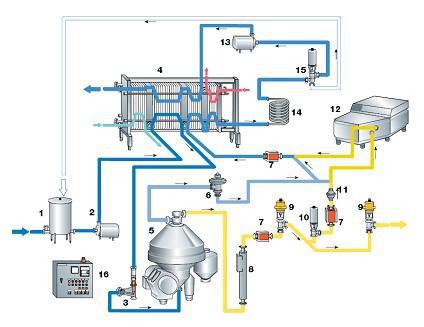

In a modern UHT plant (Ultra High Temperature) the milk is pumped through a closed system. On the way it is preheated, highly heat treated, homogenized, ultra highly heat treated, cooled and packed aseptically. Low acid (pH above 4.5 – for milk more than pH 6.5) liquid products are usually treated at 135 – 150C for a few seconds holding, by either indirect heating or direct steam injection or infusion. High acid (pH below 4.5) products such as juice are normally heated at 90 – 95C for 15 – 30 seconds holding. All parts of the system downstream of the actual highly heating section are of aseptic design to eliminate the risk of reinfection, include aseptic packaging in packages protecting the product against light and atmospheric oxygen. Ambient storage is normal.

Various UHT systems:

There are two main types of UHT systems on the market.

- In the direct systems the product comes in direct contact with the heating medium, followed by flash cooling in a vacuum vessel and eventually further indirect cooling to packaging temperature. The direct systems are divided into:

•steam injection systems (steam injected into product),

•steam infusion systems (product introduced into a steam-filled vessel).

- In the indirect systems the heat is transferred from the heating media to the product through a partition (plate or tubular wall). The indirect systems can be based on:

•plate heat exchangers,

•tubular heat exchangers,

•scraped surface heat exchangers,

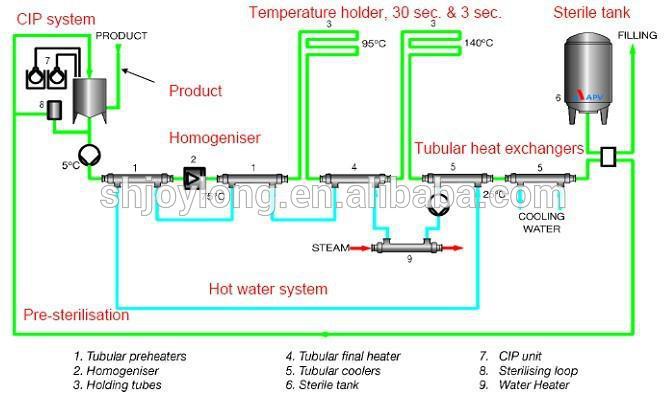

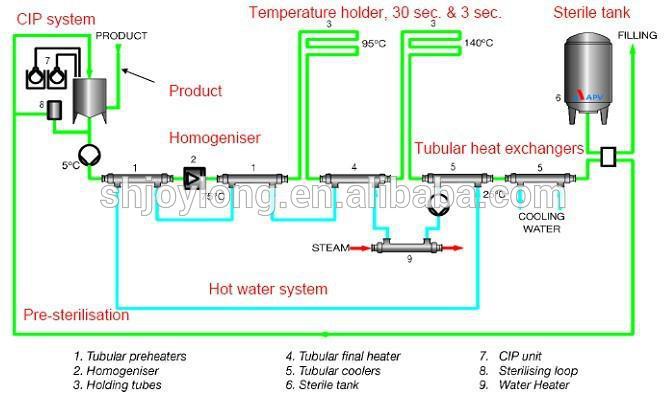

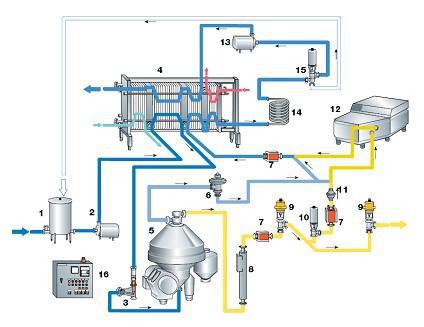

Furthermore it is possible to combine the heat exchangers in the direct systems according to product and process requirements The figure below is an indirect system - tubular UHT plant as an example Whole line including: 1.Water Treatment section 2.Milk Receiving or powder dissolving Section 3.Preparation Section 4.UHT Sterilization Section 5.Filling & Packaging Section 6.CIP Cleaning Section 7.Chiller 8.Compressor 9. Steam Boiler 10. Installation Material Technical parameters

Technical parameters

1.Longlife service

2.CE,ISO certificate

3.High quality

4. Good service

Complete pasteurized uht milk processing machinery system

Description:

Description:With a product that can be stored for long periods without spoiling and with no need for refrigeration, there are many advantages for both the producer, the retailer and the consumer. This includes expensive products such as cream, desserts and sauces.

In a modern UHT plant (Ultra High Temperature) the milk is pumped through a closed system. On the way it is preheated, highly heat treated, homogenized, ultra highly heat treated, cooled and packed aseptically. Low acid (pH above 4.5 – for milk more than pH 6.5) liquid products are usually treated at 135 – 150C for a few seconds holding, by either indirect heating or direct steam injection or infusion. High acid (pH below 4.5) products such as juice are normally heated at 90 – 95C for 15 – 30 seconds holding. All parts of the system downstream of the actual highly heating section are of aseptic design to eliminate the risk of reinfection, include aseptic packaging in packages protecting the product against light and atmospheric oxygen. Ambient storage is normal.

Various UHT systems:

There are two main types of UHT systems on the market.

- In the direct systems the product comes in direct contact with the heating medium, followed by flash cooling in a vacuum vessel and eventually further indirect cooling to packaging temperature. The direct systems are divided into:

•steam injection systems (steam injected into product),

•steam infusion systems (product introduced into a steam-filled vessel).

- In the indirect systems the heat is transferred from the heating media to the product through a partition (plate or tubular wall). The indirect systems can be based on:

•plate heat exchangers,

•tubular heat exchangers,

•scraped surface heat exchangers,

Furthermore it is possible to combine the heat exchangers in the direct systems according to product and process requirements The figure below is an indirect system - tubular UHT plant as an example Whole line including: 1.Water Treatment section 2.Milk Receiving or powder dissolving Section 3.Preparation Section 4.UHT Sterilization Section 5.Filling & Packaging Section 6.CIP Cleaning Section 7.Chiller 8.Compressor 9. Steam Boiler 10. Installation Material

Technical parameters

Technical parameters Raw material | Fresh cow milk, powder milk |

Product | UHT whole milk, UHT skimmed milk, UHT flavor milk, etc |

Capacity | 2T/D – 500T/D |

Product package | aseptic carton , Pillow shape aseptic pouch, plastic bottle, etc |

Send your inquiry to this supplier

Send Inquiry