1 / 5

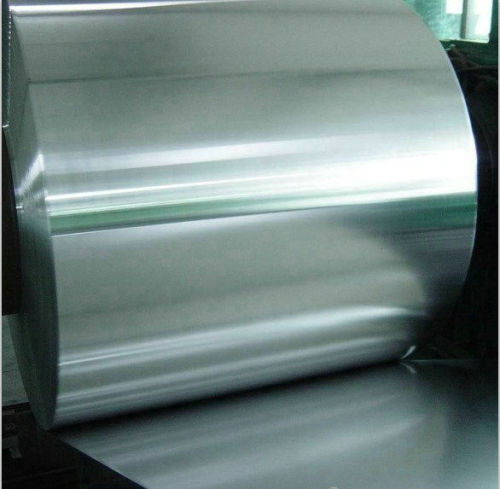

Cold Rolled Austenitic Sus304l Stainless Steel Coil / Strip With 0.05-0.8mm Thickness

Product description

Cold rolled Austenitic SUS304L Stainless Steel Coil / strip with 0.05-0.8mm thickness

SUS304L cold rolled stainless steel strip with thickness:0.05-0.8mm width:4-600mm Thickness tolerance: +/-0.005mm HV160-400 Surface:2B BA

Specifications:

Chemical composition:

|

Name |

C |

Mn |

Si |

P |

S |

Cr |

Ni |

|

304L |

≤0.030 |

≤2.00 |

≤1.00 |

≤0.045 |

≤0.03 |

18.00~20.00 |

9.00~13.00 |

Mechanical Properties :

|

N/mm2 |

σb (MPa) |

σs (MPa) |

δ5 (%) |

Hardness |

Density |

Specific heatC(20℃) |

Melting point |

Resistivity |

|

>=205 |

>=520 |

>=205 |

>=40 |

<=187HB,<=90HRB,<=200HV |

7.93g/cm3 |

0.502J*(g.c)-1 |

1398~1420℃ |

0.73Ώ*mm2*m-1 |

|

Temperature℃ |

20 |

100 |

500 |

|

Thermal conductivity λ/w(m*℃)-1 |

12.1 |

16.3 |

21.4 |

|

Temperature℃ |

20-200 |

20-200 |

20-300 |

20-400 |

|

Coefficient of linear expansionα/(10-6/℃) |

16.0 |

16.8 |

17.5 |

18.1 |

Brief Description:

Thickness(0.05—0.8mm) × Width(4—600mm)

Thickness tolerance(±0.005--±0.01mm)

Width tolerance(±0.05mm)

Hardness:HV160-HV400

Other sizes as your requirements to produce.

We can provide free samples if you have any questions, contact us, we discuss the details!

Surface:

304L stainless steel manufacturing process, the surface treatment method, and the mechanical polishing surface treatment method

Summary of the manufacturing method of surface features uses

NO.1 silver white, matte hot rolled to the required thickness, then annealing and phosphorus removal a rough matte surface does not require the use of the surface gloss

NO.2D silver white cold rolled after heat treatment and pickling, and sometimes face in hair rollers the final a strife a matt surface processing 2D products for use lax, surface, general timber, deep red timber

NO.2B gloss stronger than NO.2D NO.2D treatment, and ultimately a mild cold rolled polished rolls, in order to obtain the proper luster. This is the most common surface machining, and the machining can also be used as the first portion of the polishing. General timber

BA bright as a mirror standard, but usually bright annealed surface processing, high surface reflectivity. Building materials, kitchen utensils

NO.3 rough grinding NO.2D and NO.2B material with 100-200 # (units) abrasive grains of the polishing tape, the grinding of construction materials, kitchen utensils

NO.4 intermediate grinding obtained NO.2D, and NO.2B material, the abrasive grains 150 to # 180 polishing tape polishing the polishing surface, which is common, the specular reflection with a visible 'grain' shiny surfaces ditto

NO.240 fine grinding use NO.2D and NO.2B material, grinding and grinding with abrasive grains 240 # kitchen utensils

NO.320 very fine grinding use NO.2D and NO.2B material, 320 # abrasive grains abrasive belt grinding ibid.

NO.400 gloss close the BA will NO.2B material with # 400 polishing wheel grinding general timber construction material, kitchen utensils

HL Hairline grinding appropriate particle size of the abrasive material hairline grinding (150 to # 240) abrasive grains a lot of buildings, building materials

NO.7 close to mirror polishing 600 # rotary polishing wheel grinding art with decorative

NO.8 mirror-polished mirror polishing wheel for grinding mirrors, decorative

Density:

|

Steel Grade |

Density(g/cm3) |

|

201,202,301,302,303, 304,304L,305,321 |

7.93 |

|

316,316L,316S,347,309S,310,310S |

7.98 |

|

405,410,420 |

7.75 |

|

409,430,434 |

7.7 |

Stainless steel theoretical weight formula:

Weight (kg) = thickness (mm) × width (mm) x length (mm) × density values

Stainless steel gravity:

Chromium stainless take 7.75 ton / M3

Chrome-nickel stainless steel take 7.93 ton / M3

Iron take 7.87 ton / M3

Description:

304L stainless steel in the 304 stainless steel on the basis of low-carbon, increased content of nickel and chromium, the development of 304L stainless steel, has corrosion resistance, elongation, appearance, workability, strength, and other characteristics of the 304L stainless steel is far more than the other materials,Moreover, the stainless steel surface treatment method, you can obtain a variety of colors and shapes, which makes a significant contribution for the development of the stainless steel.

Austenitic steels, uses the most widely used, excellent corrosion resistance, heat resistance, low temperature strength and mechanical properties, single-phase austenite hardening heat treatment (non-magnetic, temperature-196-8000C). With SUS304 all characteristics, corrosion resistance and excellent heat resistance; after welding or eliminate stress, can also maintain good corrosion resistance, drawability, excellent polishing properties.SUS304L with SUS304 all features; excellent in corrosion resistance and heat resistance; or eliminate stress, able to maintain good corrosion resistance after welding; deep drawability and excellent polishing properties.

Applications:

Mainly used for Electronics, computer accessories, stationery, kitchen utensils, medical equipment, stainless steel etching materials, chemical packing, needle material,spiral wound gasket, seal.

Applied to the high resistance to intergranular corrosion, chemical, coal, petroleum environment instruments and equipment; outdoor decorative materials, heat-resistant parts and heat treatment difficult parts. Frozen Container Frame and exterior materials, car exhaust pipe (800 ℃), heat-resistant equipment parts.

Competitive Advantage:

First-class quality, complete specifications, reasonable price, timely delivery and rigorous specified according to customer requirements, suited materials for basic principles, to allow customers to buy satisfaction with assured.

Send your inquiry to this supplier