1 / 5

Russia style wall tiles equipment

$12500.00

≥1 Set/Sets

Model:

- XF 15-170

Maximum working width:

- 250 mm

| Model No. : | XF15-170wall board Forming Machine |

|---|---|

| Brand Name : | XF |

| Types of : | Steel Frame &Amp; Purlin Machine |

Cangzhou, Hebei, China

- Manufacturer

- OEM service

- Platform Certification

- SGS Certification

- Online Expo

- Video

Product description

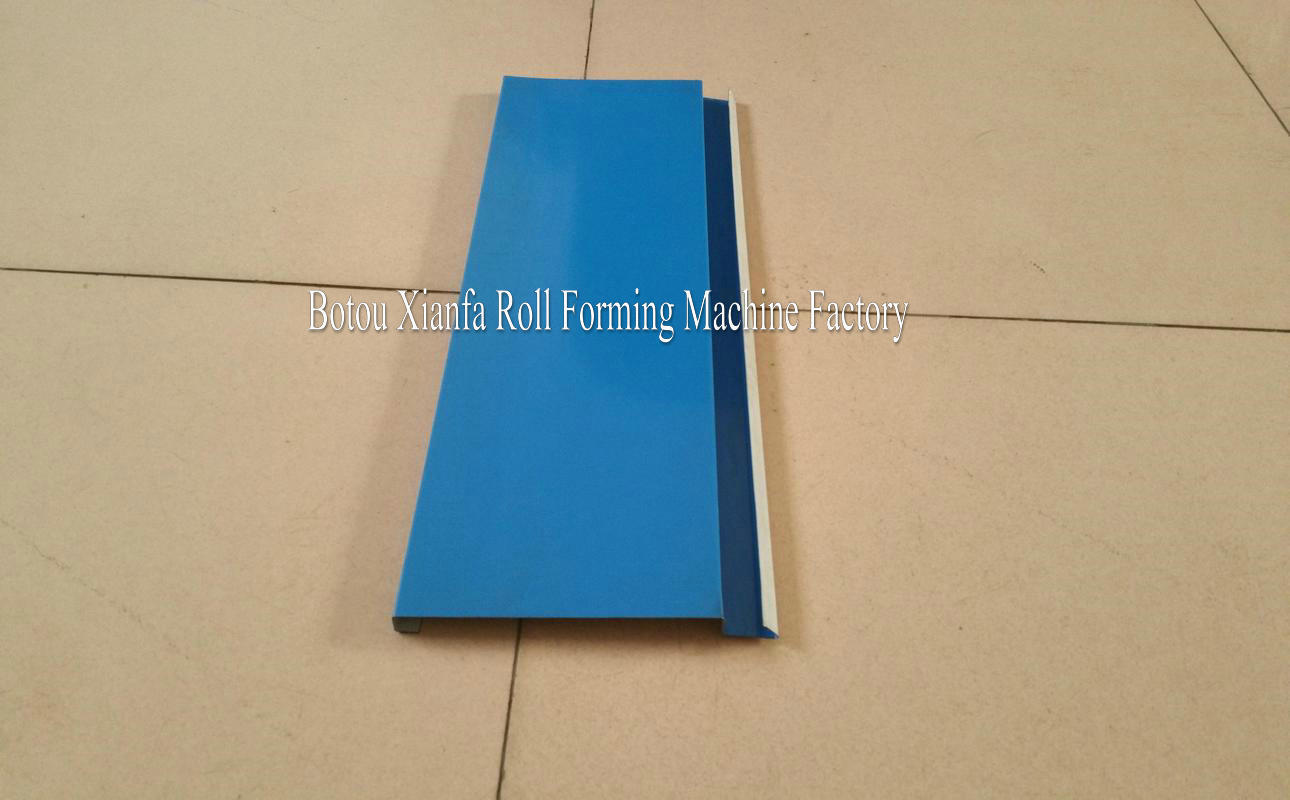

Wall Roll Forming Machine for Uzbekistan. The width coils for Wall Panel Machine is 250mm. Speed of Automatic Profile Rolling Machine will up to 15m/min. Station of Iron Sheet Making Machine is 12 rows. If you need Roll Forming Machine for other profile sheet,pls contact us.

Russia style wall tiles equipment

Cold Steel wall board Forming Machine,Russia style wall tiles Forming Machine,wall tiles production line

Russia style wall tiles equipment Quick Detail

1.Suitable to process: Color steel plate

2.Width of the plate: 250mm

3.Rollers:12rows

4.Dimensions: 6.6*1.35*1.51m

5.Power: 3+3kw

6.Thickness of the plate:0.3-0.6mm

7.Diameter of the roller:Φ60mm

8.Weight: About 2.8T

9.Voltage: 380V 50Hz 3phases

10.Hydraulic: 40#

11.Processing precision: Within 1.00mm

12.Control system: PLC control

Russia style wall tiles equipment Equipment including components

Uncoiler

Usage:It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand.

Loading capacity:3000KG.Inner diameter: 500-508mm

Roller

Material of rollers:45# steel,roller surfaces polishing, hard plating , The polished surface and the heat treatment towards the

molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Hydraulic and Control Systems

Hydraulic oil: 40#

hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

The target piece`s length is adjustable and digit of it can be adjusted.

Computed mode has two modes: automatic and manual one. The system is easy to operate and use

PLC: EURA(Can customize as customer require)

Shearing Mechanism

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products

Material of blades: Cr12,quenching treatment

Output Table

It adopts welded steel and supported roller to transmit the products,which is used to collect the finished products.

Russia style wall tiles equipment Packaging & Shipping

1.We have professional technicians for loading

Guaranteed the goods load into container without any damage.

2. Transportation : Machines need one 40 feet container to hold

3.Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you

Russia style wall tiles equipment Payment method

Method 1:30% deposit by T/T in advance and 70% balance after inspection confirmation before shipment

Method 2:L/C is also acceptable.

Installation, Commissioning, Test and Training

1. The engineers from the Seller shall supervise the installation on site and fulfill the commissioning.

They should start off within 10 days after they get the information from the Buyer.

2. The Buyer shall pay for the international air tickets and the local, such as board and lodging, daily transportation, communication,Insurance,

etc. The Buyer shall pay USD 100 /day /person to the Seller for the commissioning.

3. The Buyer shall prepare an interpreter for better communication between the two sides.

Looking for ideal Roofing Roll Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative.

All the Roofing Roll Forming Machine are quality guaranteed. We are China Origin Factory of Roll Forming Machine

If you have any question, please feel free to contact us.

Product Categories :Manufacturing & Processing Machinery > Building Material Making Machinery > Tile Making Machine

Cangzhou, Hebei, China

- Manufacturer

- OEM service

- Platform Certification

- SGS Certification

- Online Expo

- Video

Send your inquiry to this supplier