1 / 5

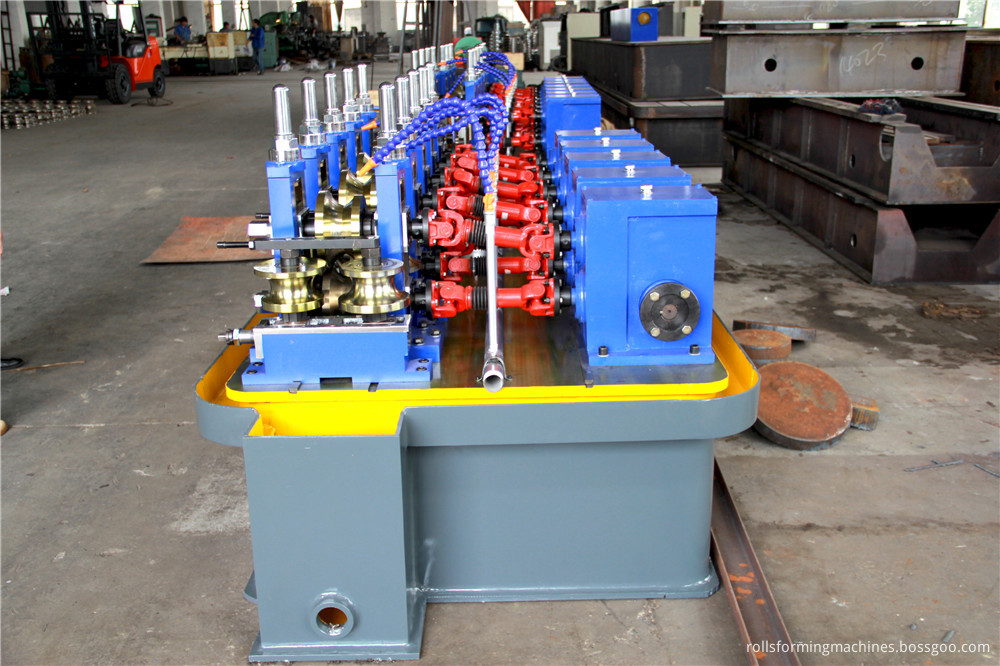

Chinese tube production machine/tube roll forming mill line

| Brand Name : | Zhongtuo |

|---|

Cangzhou, Hebei, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Video

Product description

Chinese tube production machine/tube roll forming mill line

Basic information of welded pipe roll forming machine:

1. Round Pipe diameter: Φ38 –Φ102mm

Pipe Thickness: 1.0 – 5.0mm

2. Square Pipe: 20X20mm – 80X80mm

Rectangle Pipe: 20X30mm – 60X80mm

Pipe Thickness: 1.0 – 3.0mm

3. Pipe Length: 6.0m – 12.0m

4. Length Tolerance: 0-6mm

The

mill is intended for manufacturing of round pipe of Φ38mm-Φ102mm with thickness

of 1.0mm–3.0mm from cold-rolled and hot-rolled coil strip by means of unclosed

tubular blank with its subsequent welding into tube, edge heating by means of

solid state high-frequency welder, longitudinal seam welding in rolls of tube

welding machine, cooling, further sizing or shaping and on-stream cutting of

endless tube in measured lengths. Finished

product will be of round, square or rectangular pipe.

Specification of steel pipe machine :

SteelTape Specification

1. Material: Low Carbon steel (σb≤500Mpa,σs≤235Mpa)

2. Steel Tape: Inner diameter: Φ470-Φ510mm

Outer diameter: Φmax=1500mm

Strip steel width: 40mm-240mm

The maximum weight: 2.0 tons

c) Electricity

1. Dynamic power: AC380V±10%, 3phases, 50Hz±1.0%

2. Control Power: AC220V±10%, one phase, 50 Hz ±1.0%

d) Electric installed capacity: appro. 250KW

e) Cooling water

1. Reservoir for High Frequency equipment: 15 m³, one set

2. Reservoir for circulating cooling water: 15 m³, one set

IV. Equipment makeup and main parameters of single unit:

1. Double-head un-coiler

1.1. Briefing: Rotary type to change coils easily, with a pneumatic brake

1.2. Parameters:

- Coil width: max.240mm

- Coil OD: max. Ø1500mm

- Coil ID: Ø 470- Ø 510mm

- Coil weight: max. 2.0 tons

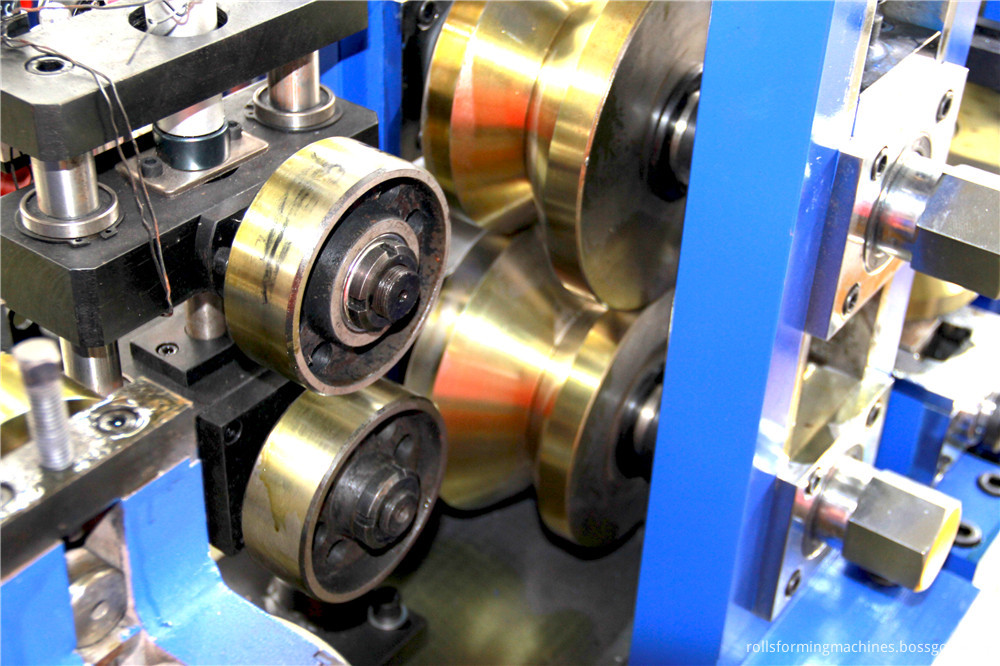

4.1.2 Welding pipe machine Forming mill consists of:

- Driven stand: 7 sets (Horizontal)

- Driven stand shaft: Ø60mm

- Material of shaft: 40Cr

- Side roll stand: 8 sets(Vertical)

- Side roll stand shaft: Ø40mm

- Material of shaft: 40Cr

- Gear box & universal joint: 7 sets

- Material of gear box: cast steel

- Material of gear: 20CrMnTi

- Main motor: 55kW model: Z4-200-31 1 set

- Main redactor: ZLY224 1 set

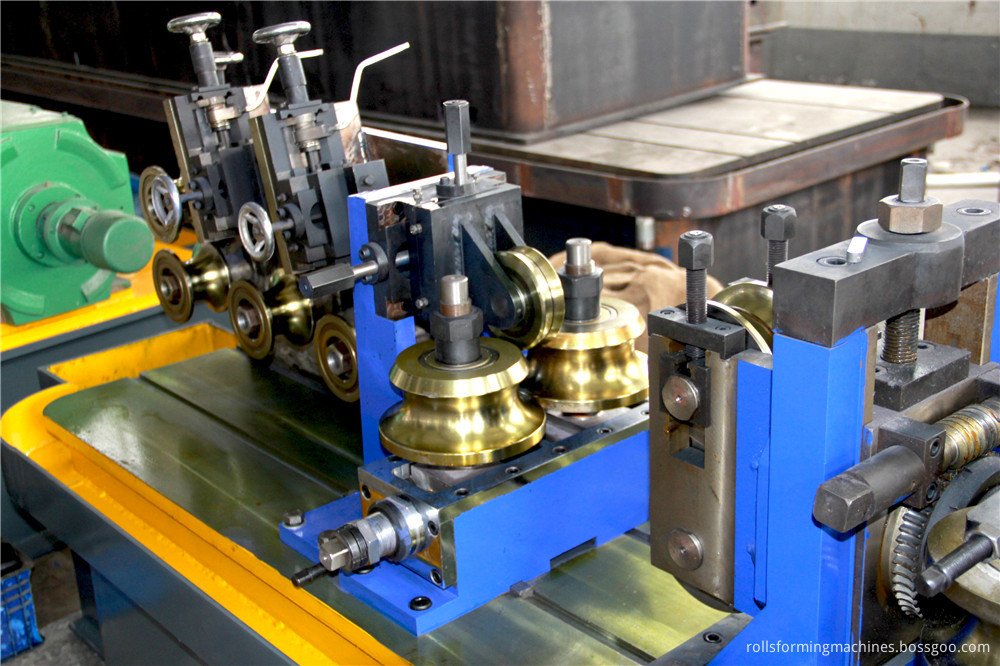

4.2 Sizing mill gear box, universal joint

4.2.1 Sizing mill consist of:

- Driven stand: 5 sets (Horizontal)

- Driven stand shaft: Ø60mm

- Material of shaft: 40Cr

- Side roll stand: 5 sets(Vertical)

- Side roll stand shaft: Ø40mm

- Material of shaft: 40Cr

- Gear box & universal joint: 5 sets

- Material of gear box: cast steel

- Material of gear: 20CrMnTi

- Main motor: 55kW Model: Z4-200-31 1 set

- Main redactor: ZLY224 1 set

- 2 sets single head Turk`s head, with 4 rollers*2sets

- One speed testing roller with air cylinder for CNC flying saw

Cangzhou, Hebei, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Video

Send your inquiry to this supplier