1 / 3

China wood drying chamber, timber drying machine, wood drying kiln

Get Latest Price

Send Inquiry

| Model No. : | XN20 |

|---|---|

| Brand Name : | XINAN |

Jiangsu Xinan Wood Drying Equipment Co., Ltd.

You might also like

Product description

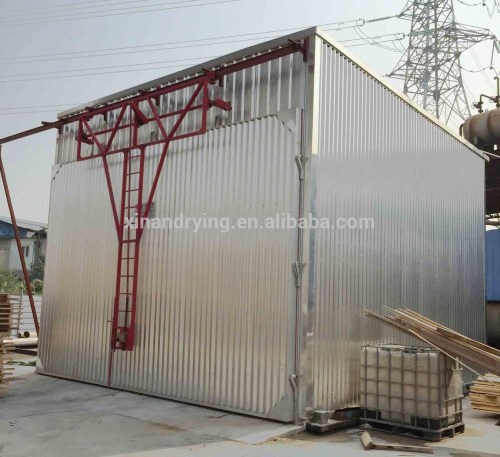

XINAN WOOD DRYING MACHINE 20m3 wood drying chamber, timber drying machine, wood drying kiln  Product Description Drying Timber capacity: 20m3 Model: XNQ-MaA20 Chamber dimension: 3.8*4.6*4.8 (customized) Chamber material: aluminum alloy Door : hanging and sliding Heating medium: steam, hot water, hot oil, gas and electricity Controlling system: automatic Moisture content: control as setted

Product Description Drying Timber capacity: 20m3 Model: XNQ-MaA20 Chamber dimension: 3.8*4.6*4.8 (customized) Chamber material: aluminum alloy Door : hanging and sliding Heating medium: steam, hot water, hot oil, gas and electricity Controlling system: automatic Moisture content: control as setted  Why woodworking need our XINAN dying product: No matter the wood is used as a construction material, or as a structural support or in woodworking objects, it will absorb or desorb moisture until it is in equilibrum with its surrounding. But wood drying unequally or too rapidly, shrinkage in the wood will cause damage to it. Our series of drying system will improve the wood drying quality efficiently, satisfying your requirement all the time.

Why woodworking need our XINAN dying product: No matter the wood is used as a construction material, or as a structural support or in woodworking objects, it will absorb or desorb moisture until it is in equilibrum with its surrounding. But wood drying unequally or too rapidly, shrinkage in the wood will cause damage to it. Our series of drying system will improve the wood drying quality efficiently, satisfying your requirement all the time.  Description Conventional dying kiln technical parameter

Description Conventional dying kiln technical parameter

Kiln size: customized, design as your requirement, according to your factory condition and needed drying wood. Kiln material choice Concrete and brick housing structure; All - aluminum structure; Stainless steel Drying heating medium choice: Hot water Steam Electricity Gas Hot oil Filling wood piles method: 1. By forklift; 2. By rail truck. THE WHOLE PROCESS OF XINAN DRYING SYSTEM:  Step 1: Wood shavings , sawdust or other wastes are collected in the bunker; Step 2: Then they are sent to the boiler; Step 3: Steam/ hot water/ hot oil/ gas is sent to the kiln as heating medium. Installation by XINAN professionals

Step 1: Wood shavings , sawdust or other wastes are collected in the bunker; Step 2: Then they are sent to the boiler; Step 3: Steam/ hot water/ hot oil/ gas is sent to the kiln as heating medium. Installation by XINAN professionals

overview of the kiln Wood piling and drying

overview of the kiln Wood piling and drying

Packaging & Shipping Separate package for control system, kiln chambers parts, spraying system, heating system and relative accessories. Our Services ♥ 24 hours at work for your consult or any question; ♥ One year warranty ; ♥ Engineer or professionals overseas help if needed. Company Information Institute of Drying Technology of Nanjing Forestry University and Jiangsu XINAN Wooddrying Systems Co., LTD are specialized entities with solid technical strength in scientific research and equipment making on wood drying. They belonging to NFU., are modern high-tech enterprises incorporating production, study and scientific research. They have 2Ph.D advisors, 5 well-known professors and expert enjoying government allowance from the State Council. Several experts with PH.D and Master Degree pursue research and practice on wood drying technology,wood dry equipment and control system over a long period of time and have been awarded a variety of prizes and honors. Their headquarter is set up in Nanjing, the capital city of Jiangsu Province and their factory is located in Jiangyin, a developed city in Jiangsu province. Wood drying equipments produced by XINAN are now in used not only in many furniture manufacturers, timber floor plants, cabinet work plants, shipyard and rolling stock plants in the north, south, east, southeast and southwest of china but also in southeast Asia, Africa, Europe, Russia and Ukraine, XINAN enjoys great prestige both at home and abroad for the excellent performance and reliability of its products. In order to preserve precious national broad-leaved forest, more and more importance is attached to artificial needle-bearing trees by more nations all over the world.

Packaging & Shipping Separate package for control system, kiln chambers parts, spraying system, heating system and relative accessories. Our Services ♥ 24 hours at work for your consult or any question; ♥ One year warranty ; ♥ Engineer or professionals overseas help if needed. Company Information Institute of Drying Technology of Nanjing Forestry University and Jiangsu XINAN Wooddrying Systems Co., LTD are specialized entities with solid technical strength in scientific research and equipment making on wood drying. They belonging to NFU., are modern high-tech enterprises incorporating production, study and scientific research. They have 2Ph.D advisors, 5 well-known professors and expert enjoying government allowance from the State Council. Several experts with PH.D and Master Degree pursue research and practice on wood drying technology,wood dry equipment and control system over a long period of time and have been awarded a variety of prizes and honors. Their headquarter is set up in Nanjing, the capital city of Jiangsu Province and their factory is located in Jiangyin, a developed city in Jiangsu province. Wood drying equipments produced by XINAN are now in used not only in many furniture manufacturers, timber floor plants, cabinet work plants, shipyard and rolling stock plants in the north, south, east, southeast and southwest of china but also in southeast Asia, Africa, Europe, Russia and Ukraine, XINAN enjoys great prestige both at home and abroad for the excellent performance and reliability of its products. In order to preserve precious national broad-leaved forest, more and more importance is attached to artificial needle-bearing trees by more nations all over the world.

To meet this trend, XINAN cooperated comprehensively with Vortex Engineering LTD of New Zealand, imported the ripe technology on drying of New Zealand pine from Vortex Engineering LTD and the ripe experiences on drying of soft wood from Tachikawa Forest Products LTD of Japan, and then produced successfully its own equipments for fast drying of soft wood in the year of 2004. The first 3 sets of such equipment have been put into operation in Tachikawa Forest Products LTD.

XINAN has been making ceaseless efforts to improve wood drying technology and equipments with its out standing experts and abundant experiences and will always do its best for wood processing industry all over the world. XINAN FINISHED CASES XINAN CERTIFICATES

XINAN CERTIFICATES  EXHIBITION XINAN ATTENED:

EXHIBITION XINAN ATTENED:

2015 FMC CHINA FAQ 1. All of the drying kiln can be customized? with different size and dimension? * Yes, all of the kiln can be manufactured with what you need acturally, from timber capacity 20 to 200 cubic meter. 2. What's the production time? * It depends on your order, especially for kiln size, it's takes within 30 days generally. 3. How to get the technical data, such as kiln temperature, humidity , air circulation amount? * Our XN-Q10 automatic control system shows the details when the kiln works. 4. How to dry the timber? * Do as our Kiln Manual Instruction, one step by one step, and learn how to operate the XN-Q10 control system, which shares 30 drying standard for different wood specises for your choice. 5. How to pay the order? T/T is acceptable. All we pursuit is your recognization to our products and service, if you have any problem, just contact us! website: http://www.xinandry.com contact: Grace sales skype: xy386072315 Mobile: +86 13347805711

2015 FMC CHINA FAQ 1. All of the drying kiln can be customized? with different size and dimension? * Yes, all of the kiln can be manufactured with what you need acturally, from timber capacity 20 to 200 cubic meter. 2. What's the production time? * It depends on your order, especially for kiln size, it's takes within 30 days generally. 3. How to get the technical data, such as kiln temperature, humidity , air circulation amount? * Our XN-Q10 automatic control system shows the details when the kiln works. 4. How to dry the timber? * Do as our Kiln Manual Instruction, one step by one step, and learn how to operate the XN-Q10 control system, which shares 30 drying standard for different wood specises for your choice. 5. How to pay the order? T/T is acceptable. All we pursuit is your recognization to our products and service, if you have any problem, just contact us! website: http://www.xinandry.com contact: Grace sales skype: xy386072315 Mobile: +86 13347805711

Product Description Drying Timber capacity: 20m3 Model: XNQ-MaA20 Chamber dimension: 3.8*4.6*4.8 (customized) Chamber material: aluminum alloy Door : hanging and sliding Heating medium: steam, hot water, hot oil, gas and electricity Controlling system: automatic Moisture content: control as setted

Product Description Drying Timber capacity: 20m3 Model: XNQ-MaA20 Chamber dimension: 3.8*4.6*4.8 (customized) Chamber material: aluminum alloy Door : hanging and sliding Heating medium: steam, hot water, hot oil, gas and electricity Controlling system: automatic Moisture content: control as setted  Why woodworking need our XINAN dying product: No matter the wood is used as a construction material, or as a structural support or in woodworking objects, it will absorb or desorb moisture until it is in equilibrum with its surrounding. But wood drying unequally or too rapidly, shrinkage in the wood will cause damage to it. Our series of drying system will improve the wood drying quality efficiently, satisfying your requirement all the time.

Why woodworking need our XINAN dying product: No matter the wood is used as a construction material, or as a structural support or in woodworking objects, it will absorb or desorb moisture until it is in equilibrum with its surrounding. But wood drying unequally or too rapidly, shrinkage in the wood will cause damage to it. Our series of drying system will improve the wood drying quality efficiently, satisfying your requirement all the time.  Description Conventional dying kiln technical parameter

Description Conventional dying kiln technical parameter Model | Wood Capacity(m3) | Kiln Dimension (m) | Power (KW)

|

XN20 | 20 | 4.3×4.8×4.8 | 6 |

XN30 | 30 | 4.3×5.6×4.8 | 6 |

XN40 | 40 | 4.3×6.6×5.6 | 9 |

XN50 | 50 | 6.4×6.0×5.6 | 9 |

XN60 | 60 | 6.4×6.6×5.6 | 9 |

XN80 | 80 | 9.0×6.6×5.6 | 15 |

XN100 | 100 | 9.0×8.6×5.6 | 15 |

XN120 | 120 | 10.5×8.6×5.6 | 18 |

XN150 | 150 | 13.5×8.6×5.6 | 21 |

XN200 | 200 | 15.8×8.6×5.6 | 27 |

Step 1: Wood shavings , sawdust or other wastes are collected in the bunker; Step 2: Then they are sent to the boiler; Step 3: Steam/ hot water/ hot oil/ gas is sent to the kiln as heating medium. Installation by XINAN professionals

Step 1: Wood shavings , sawdust or other wastes are collected in the bunker; Step 2: Then they are sent to the boiler; Step 3: Steam/ hot water/ hot oil/ gas is sent to the kiln as heating medium. Installation by XINAN professionals

overview of the kiln Wood piling and drying

overview of the kiln Wood piling and drying

Packaging & Shipping Separate package for control system, kiln chambers parts, spraying system, heating system and relative accessories. Our Services ♥ 24 hours at work for your consult or any question; ♥ One year warranty ; ♥ Engineer or professionals overseas help if needed. Company Information Institute of Drying Technology of Nanjing Forestry University and Jiangsu XINAN Wooddrying Systems Co., LTD are specialized entities with solid technical strength in scientific research and equipment making on wood drying. They belonging to NFU., are modern high-tech enterprises incorporating production, study and scientific research. They have 2Ph.D advisors, 5 well-known professors and expert enjoying government allowance from the State Council. Several experts with PH.D and Master Degree pursue research and practice on wood drying technology,wood dry equipment and control system over a long period of time and have been awarded a variety of prizes and honors. Their headquarter is set up in Nanjing, the capital city of Jiangsu Province and their factory is located in Jiangyin, a developed city in Jiangsu province. Wood drying equipments produced by XINAN are now in used not only in many furniture manufacturers, timber floor plants, cabinet work plants, shipyard and rolling stock plants in the north, south, east, southeast and southwest of china but also in southeast Asia, Africa, Europe, Russia and Ukraine, XINAN enjoys great prestige both at home and abroad for the excellent performance and reliability of its products. In order to preserve precious national broad-leaved forest, more and more importance is attached to artificial needle-bearing trees by more nations all over the world.

Packaging & Shipping Separate package for control system, kiln chambers parts, spraying system, heating system and relative accessories. Our Services ♥ 24 hours at work for your consult or any question; ♥ One year warranty ; ♥ Engineer or professionals overseas help if needed. Company Information Institute of Drying Technology of Nanjing Forestry University and Jiangsu XINAN Wooddrying Systems Co., LTD are specialized entities with solid technical strength in scientific research and equipment making on wood drying. They belonging to NFU., are modern high-tech enterprises incorporating production, study and scientific research. They have 2Ph.D advisors, 5 well-known professors and expert enjoying government allowance from the State Council. Several experts with PH.D and Master Degree pursue research and practice on wood drying technology,wood dry equipment and control system over a long period of time and have been awarded a variety of prizes and honors. Their headquarter is set up in Nanjing, the capital city of Jiangsu Province and their factory is located in Jiangyin, a developed city in Jiangsu province. Wood drying equipments produced by XINAN are now in used not only in many furniture manufacturers, timber floor plants, cabinet work plants, shipyard and rolling stock plants in the north, south, east, southeast and southwest of china but also in southeast Asia, Africa, Europe, Russia and Ukraine, XINAN enjoys great prestige both at home and abroad for the excellent performance and reliability of its products. In order to preserve precious national broad-leaved forest, more and more importance is attached to artificial needle-bearing trees by more nations all over the world.To meet this trend, XINAN cooperated comprehensively with Vortex Engineering LTD of New Zealand, imported the ripe technology on drying of New Zealand pine from Vortex Engineering LTD and the ripe experiences on drying of soft wood from Tachikawa Forest Products LTD of Japan, and then produced successfully its own equipments for fast drying of soft wood in the year of 2004. The first 3 sets of such equipment have been put into operation in Tachikawa Forest Products LTD.

XINAN has been making ceaseless efforts to improve wood drying technology and equipments with its out standing experts and abundant experiences and will always do its best for wood processing industry all over the world. XINAN FINISHED CASES

XINAN CERTIFICATES

XINAN CERTIFICATES  EXHIBITION XINAN ATTENED:

EXHIBITION XINAN ATTENED:

2015 FMC CHINA FAQ 1. All of the drying kiln can be customized? with different size and dimension? * Yes, all of the kiln can be manufactured with what you need acturally, from timber capacity 20 to 200 cubic meter. 2. What's the production time? * It depends on your order, especially for kiln size, it's takes within 30 days generally. 3. How to get the technical data, such as kiln temperature, humidity , air circulation amount? * Our XN-Q10 automatic control system shows the details when the kiln works. 4. How to dry the timber? * Do as our Kiln Manual Instruction, one step by one step, and learn how to operate the XN-Q10 control system, which shares 30 drying standard for different wood specises for your choice. 5. How to pay the order? T/T is acceptable. All we pursuit is your recognization to our products and service, if you have any problem, just contact us! website: http://www.xinandry.com contact: Grace sales skype: xy386072315 Mobile: +86 13347805711

2015 FMC CHINA FAQ 1. All of the drying kiln can be customized? with different size and dimension? * Yes, all of the kiln can be manufactured with what you need acturally, from timber capacity 20 to 200 cubic meter. 2. What's the production time? * It depends on your order, especially for kiln size, it's takes within 30 days generally. 3. How to get the technical data, such as kiln temperature, humidity , air circulation amount? * Our XN-Q10 automatic control system shows the details when the kiln works. 4. How to dry the timber? * Do as our Kiln Manual Instruction, one step by one step, and learn how to operate the XN-Q10 control system, which shares 30 drying standard for different wood specises for your choice. 5. How to pay the order? T/T is acceptable. All we pursuit is your recognization to our products and service, if you have any problem, just contact us! website: http://www.xinandry.com contact: Grace sales skype: xy386072315 Mobile: +86 13347805711 Send your inquiry to this supplier

Send Inquiry