1 / 6

China lightweight Autoclaved Aerated Concrete AAC Panel Making Equipment with factory price

Get Latest Price

Send Inquiry

| Model No. : | AAC Block Equipments |

|---|---|

| Brand Name : | Zhongke |

Henan Zhongke Engineering Technology Co., Ltd.

You might also like

Product description

China lightweight Autoclaved Aerated Concrete AAC Panel Making Equipment with factory price Introduction to Autoclaved Aerated Concrete (AAC) Autoclaved Aerated Concrete (AAC) block and board have become the pillar industry in construction field. China (Mainland) has introduced AAC technology before 40 years, our company is the earliest manufacture and R&D institute of Aerated Concrete (AAC) machinery, and our technology has reached the advanced level of Aerated Concrete (AAC) machine industry. The sales volume and comprehensive indexes of our Aerated Concrete (AAC) equipment are ahead of others in China (Mainland). The aerated concrete is characterized by the advantages of light weight, heat preservation, sound isolation, high strength,processable property and so on, what's more, the raw materials of AAC are abundant. Especially, it can not only make use of industrial waste residue, improve environmental pollution, and protect tillable field, but also create favorable social and economic benefits to take fly ash as the raw material of AACblock and board. Aerated concrete is the perfect wall material to replace the traditional solid clay brick.  For many years, Aerated Concrete (AAC) has always accepted strong supports from the policies about reforming of wall material, tax policies and environment protection policies. Aeroconcrete (AAC) block and board have become the important part of new-type construction materials, and possess bright development future.

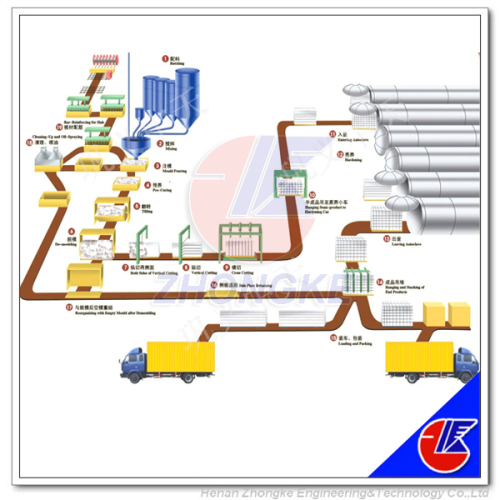

For many years, Aerated Concrete (AAC) has always accepted strong supports from the policies about reforming of wall material, tax policies and environment protection policies. Aeroconcrete (AAC) block and board have become the important part of new-type construction materials, and possess bright development future.  Production Process of Aerated Concrete Production Process of Aerated Concrete According to the category and quality of raw material, and the features of equipment, the aerated concrete can be manufactured in different processes. Generally, add water to ash, silica sand or slag and crush them into slurry; then add powdery lime, cement of right amount, plaster, vesicant, foam stabilizer, and mix and pour it to mould frame; after curing, foaming and hardening, cut it into blocks and boards in different specifications; finally, transport it into pressure steamer with steam-curing cart, and get the light cellular concrete after steam-curing with high temperature and pressure. Process Flow of an Annual Output 50,000m3---300,000m3 Aerated Concrete Steam-Curing Production (1) Various raw material storage tanks → (2) Mix dosing → (3) add water to raw material and mix them → (4) prepare the mould → (5) pour → (6) foam and wait → (7) release from mould → (8) turn up, cut horizontally and vertically → (9) make into groups and get into autoclave → (10) cure under high temperature and pressure → (11) release the finished products from the autoclave → (12) test the finished products → (13) pack → (14) stack and store up → (15) leave the factory.

Production Process of Aerated Concrete Production Process of Aerated Concrete According to the category and quality of raw material, and the features of equipment, the aerated concrete can be manufactured in different processes. Generally, add water to ash, silica sand or slag and crush them into slurry; then add powdery lime, cement of right amount, plaster, vesicant, foam stabilizer, and mix and pour it to mould frame; after curing, foaming and hardening, cut it into blocks and boards in different specifications; finally, transport it into pressure steamer with steam-curing cart, and get the light cellular concrete after steam-curing with high temperature and pressure. Process Flow of an Annual Output 50,000m3---300,000m3 Aerated Concrete Steam-Curing Production (1) Various raw material storage tanks → (2) Mix dosing → (3) add water to raw material and mix them → (4) prepare the mould → (5) pour → (6) foam and wait → (7) release from mould → (8) turn up, cut horizontally and vertically → (9) make into groups and get into autoclave → (10) cure under high temperature and pressure → (11) release the finished products from the autoclave → (12) test the finished products → (13) pack → (14) stack and store up → (15) leave the factory.  AAC producing line equipments The model and quatity of the AAC equipment will be confirmed by the designed project, according to different requirement, the pouring include fixed pouring and mobile pouring,the ground cutting is popular domestic, the other section such as the batching system,the hardening section is almost same.

AAC producing line equipments The model and quatity of the AAC equipment will be confirmed by the designed project, according to different requirement, the pouring include fixed pouring and mobile pouring,the ground cutting is popular domestic, the other section such as the batching system,the hardening section is almost same.

Main technical parameters

Main technical parameters  Packaging & Shipping

Packaging & Shipping  Packaging: Standard international export packing, container, spare parts in wooden box. Shipping: Qingdao, Tianjin,Shanghsi or depends on requirement . Delivery: 15-20 days after receiving the prepayment .

Packaging: Standard international export packing, container, spare parts in wooden box. Shipping: Qingdao, Tianjin,Shanghsi or depends on requirement . Delivery: 15-20 days after receiving the prepayment .  Company Information Henan Zhongke Engineering & Technology Co., Ltd. is specialized in heavy equipment like various crusher, stone jaw crusher, magnetic separators, mining machines, bricks and blocks machines, cement production line. AAC block line, etc. And it is located in the middle of China. Our competitive price, high quality products and excellent aftersales service had gain us good reputation in this field.

Company Information Henan Zhongke Engineering & Technology Co., Ltd. is specialized in heavy equipment like various crusher, stone jaw crusher, magnetic separators, mining machines, bricks and blocks machines, cement production line. AAC block line, etc. And it is located in the middle of China. Our competitive price, high quality products and excellent aftersales service had gain us good reputation in this field.

Main product Crushing equipment: jaw crusher, impact crusher,cone crusher, hammer crusher, sand making machine, vibrating feeder, vibrating screen; Mine-dressing equipment: ball mill, spiral chute, classifier, flotation machine, magnetic separator;

Main product Crushing equipment: jaw crusher, impact crusher,cone crusher, hammer crusher, sand making machine, vibrating feeder, vibrating screen; Mine-dressing equipment: ball mill, spiral chute, classifier, flotation machine, magnetic separator;

Building material equipment: rotary dryer, rotary kiln, autoclave aerated concrete equipment (AAC plant)

Production line: sand production line, stone production line, active lime production line, cement production line, AAC block plant

Our Services Pre-sale services Our company can be customer's assistant or adviser, we can ensure that each user’s every investment be richly rewarded. 1. Select proper equipment model;

Our Services Pre-sale services Our company can be customer's assistant or adviser, we can ensure that each user’s every investment be richly rewarded. 1. Select proper equipment model;

2. Design and manufacture products according to clients' special requirement;

3. Training technical personnel for the first-line operators

4. Our company can send technicians to customers for free, and our technical staff can design the best solution and site planning for the customer. Services during the sale We respect every customer, we can let you feel comfortable, relaxed and surprise.We are committed to improving the overallvalue of the clients. 1. Examination of the product

2. We can design construction scheme for you. After-sale services 1.Free special after-sales service personnel assigned to the scene to guide the installation and commissioning of the customer.

2. Equipment installation and adjustment.

3. Train technical personnel the first-line operators;

4. Complete sets of equipment after installation, leaving 1 to 2 full-time technical staff to assist in the production of 1 months free customer site, until the user is satisfied. Reaction rate 1.Service engineer to contact the service information after 15 minutes, the phone to explain the handling measures.

2. From receiving information services to arrive at the accident scene: Shanghai city and surrounding areas of not more than 2 hours, cross area not more than 12 hours, across the province in less than 24 hours (northwest across the region is not more than 16 hours, provinces is less than 48 hours).

3. Service Engineer 24 hours standby.

4. Failure is not completed, the service engineer can not leave the scene, leaving the site to be customer license. Contact Us

For many years, Aerated Concrete (AAC) has always accepted strong supports from the policies about reforming of wall material, tax policies and environment protection policies. Aeroconcrete (AAC) block and board have become the important part of new-type construction materials, and possess bright development future.

For many years, Aerated Concrete (AAC) has always accepted strong supports from the policies about reforming of wall material, tax policies and environment protection policies. Aeroconcrete (AAC) block and board have become the important part of new-type construction materials, and possess bright development future.  Production Process of Aerated Concrete Production Process of Aerated Concrete According to the category and quality of raw material, and the features of equipment, the aerated concrete can be manufactured in different processes. Generally, add water to ash, silica sand or slag and crush them into slurry; then add powdery lime, cement of right amount, plaster, vesicant, foam stabilizer, and mix and pour it to mould frame; after curing, foaming and hardening, cut it into blocks and boards in different specifications; finally, transport it into pressure steamer with steam-curing cart, and get the light cellular concrete after steam-curing with high temperature and pressure. Process Flow of an Annual Output 50,000m3---300,000m3 Aerated Concrete Steam-Curing Production (1) Various raw material storage tanks → (2) Mix dosing → (3) add water to raw material and mix them → (4) prepare the mould → (5) pour → (6) foam and wait → (7) release from mould → (8) turn up, cut horizontally and vertically → (9) make into groups and get into autoclave → (10) cure under high temperature and pressure → (11) release the finished products from the autoclave → (12) test the finished products → (13) pack → (14) stack and store up → (15) leave the factory.

Production Process of Aerated Concrete Production Process of Aerated Concrete According to the category and quality of raw material, and the features of equipment, the aerated concrete can be manufactured in different processes. Generally, add water to ash, silica sand or slag and crush them into slurry; then add powdery lime, cement of right amount, plaster, vesicant, foam stabilizer, and mix and pour it to mould frame; after curing, foaming and hardening, cut it into blocks and boards in different specifications; finally, transport it into pressure steamer with steam-curing cart, and get the light cellular concrete after steam-curing with high temperature and pressure. Process Flow of an Annual Output 50,000m3---300,000m3 Aerated Concrete Steam-Curing Production (1) Various raw material storage tanks → (2) Mix dosing → (3) add water to raw material and mix them → (4) prepare the mould → (5) pour → (6) foam and wait → (7) release from mould → (8) turn up, cut horizontally and vertically → (9) make into groups and get into autoclave → (10) cure under high temperature and pressure → (11) release the finished products from the autoclave → (12) test the finished products → (13) pack → (14) stack and store up → (15) leave the factory.  AAC producing line equipments The model and quatity of the AAC equipment will be confirmed by the designed project, according to different requirement, the pouring include fixed pouring and mobile pouring,the ground cutting is popular domestic, the other section such as the batching system,the hardening section is almost same.

AAC producing line equipments The model and quatity of the AAC equipment will be confirmed by the designed project, according to different requirement, the pouring include fixed pouring and mobile pouring,the ground cutting is popular domestic, the other section such as the batching system,the hardening section is almost same.  Main technical parameters

Main technical parameters  Packaging & Shipping

Packaging & Shipping  Packaging: Standard international export packing, container, spare parts in wooden box. Shipping: Qingdao, Tianjin,Shanghsi or depends on requirement . Delivery: 15-20 days after receiving the prepayment .

Packaging: Standard international export packing, container, spare parts in wooden box. Shipping: Qingdao, Tianjin,Shanghsi or depends on requirement . Delivery: 15-20 days after receiving the prepayment .  Company Information Henan Zhongke Engineering & Technology Co., Ltd. is specialized in heavy equipment like various crusher, stone jaw crusher, magnetic separators, mining machines, bricks and blocks machines, cement production line. AAC block line, etc. And it is located in the middle of China. Our competitive price, high quality products and excellent aftersales service had gain us good reputation in this field.

Company Information Henan Zhongke Engineering & Technology Co., Ltd. is specialized in heavy equipment like various crusher, stone jaw crusher, magnetic separators, mining machines, bricks and blocks machines, cement production line. AAC block line, etc. And it is located in the middle of China. Our competitive price, high quality products and excellent aftersales service had gain us good reputation in this field.

Main product Crushing equipment: jaw crusher, impact crusher,cone crusher, hammer crusher, sand making machine, vibrating feeder, vibrating screen; Mine-dressing equipment: ball mill, spiral chute, classifier, flotation machine, magnetic separator;

Main product Crushing equipment: jaw crusher, impact crusher,cone crusher, hammer crusher, sand making machine, vibrating feeder, vibrating screen; Mine-dressing equipment: ball mill, spiral chute, classifier, flotation machine, magnetic separator;Building material equipment: rotary dryer, rotary kiln, autoclave aerated concrete equipment (AAC plant)

Production line: sand production line, stone production line, active lime production line, cement production line, AAC block plant

Our Services Pre-sale services Our company can be customer's assistant or adviser, we can ensure that each user’s every investment be richly rewarded. 1. Select proper equipment model;

Our Services Pre-sale services Our company can be customer's assistant or adviser, we can ensure that each user’s every investment be richly rewarded. 1. Select proper equipment model;2. Design and manufacture products according to clients' special requirement;

3. Training technical personnel for the first-line operators

4. Our company can send technicians to customers for free, and our technical staff can design the best solution and site planning for the customer. Services during the sale We respect every customer, we can let you feel comfortable, relaxed and surprise.We are committed to improving the overallvalue of the clients. 1. Examination of the product

2. We can design construction scheme for you. After-sale services 1.Free special after-sales service personnel assigned to the scene to guide the installation and commissioning of the customer.

2. Equipment installation and adjustment.

3. Train technical personnel the first-line operators;

4. Complete sets of equipment after installation, leaving 1 to 2 full-time technical staff to assist in the production of 1 months free customer site, until the user is satisfied. Reaction rate 1.Service engineer to contact the service information after 15 minutes, the phone to explain the handling measures.

2. From receiving information services to arrive at the accident scene: Shanghai city and surrounding areas of not more than 2 hours, cross area not more than 12 hours, across the province in less than 24 hours (northwest across the region is not more than 16 hours, provinces is less than 48 hours).

3. Service Engineer 24 hours standby.

4. Failure is not completed, the service engineer can not leave the scene, leaving the site to be customer license. Contact Us

Send your inquiry to this supplier

Send Inquiry