Specifications 1. Prefab workshop

2. Well predesigned & reengineered

3. Cheap steel structure green building

4. Quick assembly

Building Type | | Prefab workshop of Industrial |

Style No. | | LYLUX #81012 |

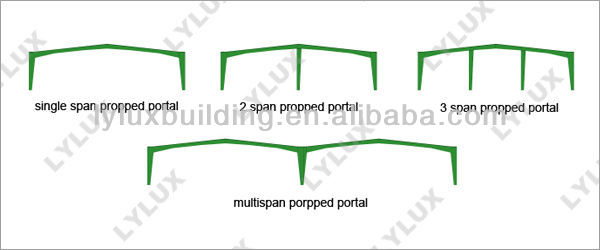

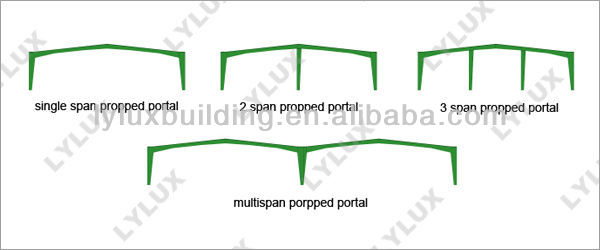

Steel Structure | | Steel portal frame |

Construction Area | | 1000m2 |

Dimension | | 50m(L) x 20m (W) x 6.8m (H) |

Storey | | 1 |

Zone Information | Warehouse | 1000m2 |

| Office | None |

Light Steel portal frame consists of the lightweight welded H-shaped steel, hot-rolled H-shaped steel, cold-formed steel , constituting a real-abdominal or portal frame lattice-type door frame as the main load-bearing skeleton. Using cold-formed steel (C-shaped, Z-shaped, etc.) to do purlins, wall beams; with pressed metal plate (pressure plate, pressure-type aluminum) to do roofing, wall; use of polystyrene foam, rigid polyurethane foam, rock wool, mineral wool, glass wool, etc., as thermal insulation materials and supported by appropriate settings of a light house architecture.

Green - Green frame, Green building materials. Safe - Anti-seismic, anti-fire, anti-corrosion. Durable - Galvanized high-strength steel frame. Quality - We provide top-quality China made prefabricated steel buildings and accessories. Cost - We pride ourselves in the fact that we always show our customers the best and least expensive way to accomplish their project.

Primary Frame | H section steel for beam and column |

Secondary Frame | C or Z section steel for wall and roof purlin |

Material | Q235B, Q345B |

Surface Treatment | Painted or Hot Dip Galvanized |

Brace | Cross support, angle brace, brace between purlin/column/beam |

Connection | Anchor bolt, ordinary bolt, high strength bolt |

Roof & Wall | Colored steel tiles or colored steel sandwich panel as per request |

Insulation for Panels | EPS, polyurethane, rock wool, glass wool |

Windows | PVC or aluminum alloy windows |

Doors | Swing, sliding or rolling door |

DESIGNING TECHNIQUE NOTES |

Materials: Steel grade should be Q235B or Q345A or above. Frame life time: Normally 50 years. Loads: Wind load, snow load, dead load, live load, etc., according to project local environment status. Span: Single-span or multi-span, 9~36m (not defined), maximum span 100m. Column spacing: Often used 6 to 9m. (6m, 7.5m, 9m) Height: Average level from 4.5 to 9m, recommend no more than 12m with bridge crane. Roof slope: 1/8-1/20. Purlin: Normally cold-formed C or Z section steel for wall and roof purlin Unit transport length: ≤ 12m Pre-punched: Pre-punched on column, beam and purlin in the factory. Connection: Q235 anchor bolts for foundation and frame join point. Rust cleaning on steel surface: Rust removed by hand is not permitted. Anticorrosion treatment: 2 primer painting (epoxy resin primer), 2 finish painting (alkyd resin paint) on steel. Fire resistance: Normally 2 hours for column, 1 hour for beam. Wall surface: Decide what kind of materials according to local environment. Roof surface: Decide what kind of materials according to local environment.

1. Consulting 2. Architectural Design 3. Building Materials Solution 4. Manufacturing 5. Construction 6. After service Please refer to LYLUX website for more service details…