Video

1 / 4

Chamber Membrane Filter Press Popular In Africa

| Model No. : | XMY80/100 |

|---|---|

| Brand Name : | Tianguan |

| Structure : | Cantilever Beam Type |

Cangzhou, Hebei, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

- Video

Product description

Chamber Membrane Filter Press Popular In Africa

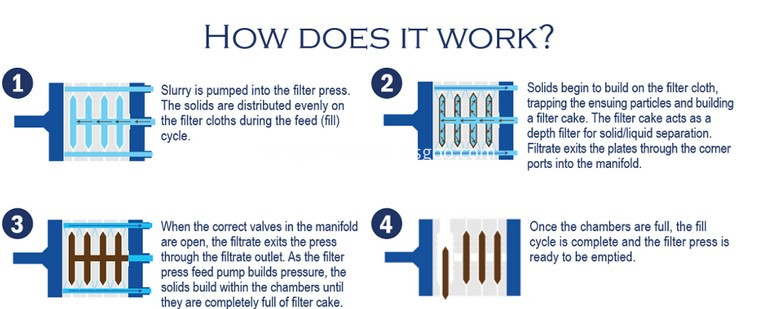

The initial operation of a membrane filter press is same to that of the common filter press, ie feeding the slurry or wastewater to the filter chamber through a centrifugal or screw or diaphragm pump.

However, once the filtration cycle is finished and final filtration pressure is achieved then the feed into the filter press will stop.

Then the plates within the Membrane Filter Press can be inflated using either air or water to exert a mechanical force on the filter cake retained in the chamber.

The effect of the squeeze is to physically compress the filter cake again and force out additional moisture held within the cake giving a drier end result.

This can reduce the moisture 20-30% lower than the common chamber filter press.

Parameters:

Features of Membrane Filter Press:

1, it adopts low pressure filtration, high pressure pressing, greatly shortening the whole filtration cycle.

2, it uses TPE elastomer, the maximum filtering pressure can reach 25 mpa, so that the moisture content is reduced greatly, and save the cost of drying, improve the yield.

3, save power consumption, operation late in filtration, small flow, high pressure.

4, the membrane pressing function, in a very short time to complete this process, save power consumption.

5, improve degree of mud biscuits, reduce rate of mud cake, diaphragm squeeze on static filter cake after the secondary crushing, the structure of the filter cake rearrangement, density increase, thus replacement part, improved the dryness.

6, strong corrosion resistance, basic is applicable to all the solid-liquid separation.

7, PLC and man-machine interface control can be configured.

8, membrane filter plate has anti-fatigue, anti-aging, sealed performance is good wait for a characteristic.

Application of Membrane Filter Press:

The membrane filter press has high squeezing pressure, good corrosion resistance advantages of convenient maintenance, safe and reliable, is metallurgy, gas, the papermaking, metallurgical, pharmaceutical, food, brewing, fine chemical industry of choice for customers. The membrane filter press has been widely used in every field in need of solid-liquid separation. The membrane filter press is considered to be the common box pressure filter replacement to upgrade equipment. Diaphragm filter press in processing capacity per unit area, reduce the filter cake moisture, the nature of processing materials showed better effect in such aspects as the adaptability.

Contact:

Video

Cangzhou, Hebei, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

- Video

Send your inquiry to this supplier