1 / 5

Nut snack bar compression molding line

| Model No. : | DRC-65 |

|---|---|

| Brand Name : | DARIN |

| Guarantee : | 1 Year |

Jinan, Shandong, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

- Video

Product description

Cereal Bar Forming Line

Instruction

Cereal Bar Forming Line is an efficient Cereal compression production Line.

This machine adopts automatic system.

PLC control, simple and convenient.

Greatly reduced manual operation.

Save costs

The Puffing Cereal Cake Machine is made of high quality of stainless steel, which used for pressing and moding puffed rice candy,rice crispy candy, peanut candy, seed candy, sesame candy, wheat,etc into round shape, ball shape, bar shap, square shape, rectangular shape by replace different molds.

All of the moulds and hoppers have been conducted with anti-stick disposal. Mechanical soft pressure will not damage nut particles with more elegant molding.

The length of cooling conveying systerm can be changed or cooling fan can be equipped based on customers requirement,so as so enhance the cooling effect.

Whole Line of Puffing Cereal Cake Machine :

Puffing Machine--Boiling Sugar Machine--Mixing Machine--Forming Machine

Sample Pictures

Features

1. The shapes can be round, cylindrical, square, semi round, triangular and blossom, etc.

2. Mechanical pressing & rubbing, does not hurt nuts, without waste.

3.Mechanical driving, accuracy positioning, upper and nether moulds tight fit, makes super cereal bar shaping.

4.Using high performance frequency inverter, easy adjust speed, high efficiency, it can produce 24-hour continuously.

5. Moulds and hopper are both non-sticky processed. All the parts may contacts food are all non-toxic material, oil and high temperature resistance.

6. Cooling conveyer can be customized as demand.

Techinical Parameters

Output

Installed Capacity

Actual Capacity

Voltage / Frequency

Dimension

Workers Required

300-400kg/hr

10kw

7kw

380V 50Hz

11 x 4 x 2m

3

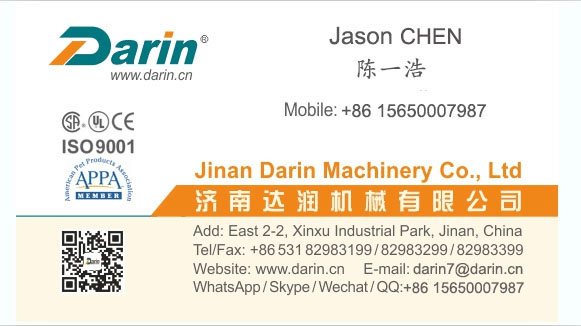

Our Office

Attended Exhibitions

Jinan, Shandong, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

- Video

Send your inquiry to this supplier