1 / 4

CE ISO SGS Certificates Biomass Pellet Production Line

| Brand Name : | Kingoro |

|---|---|

| Voltage : | 380V |

Jinan, Shandong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Video

Product description

Product Description Wood Pellet Production Line:

CE ISO SGS Certificates Wood Pellet Production Line is usually designed according to actual situation of customer, including chipping, milling, screening, drying, pelletizing, cooling, packing sections. The main section is pelletizing.

Wood Pellet Making Machine is developed based on the flat die pellet machine, which is specialized for biomass fuel pelletizing, and it adopted the unique principle of vertical structure advantages, can compress the pellet in high efficiency and low energy consumption.

Avaliable Models

| Model | Power(kw) | Capacity(t/h) | Weight(t) |

| SZLH470 | 55 | 0.7-1 | 3.6 |

| SZLH560 | 90 | 1.2-1.5 | 5.6 |

| SZLH580 | 90 | 1-1.5 | 5.5 |

| SZLH600 | 110 | 1.3-1.8 | 8.6 |

| SZLH660 | 132 | 1.5-2 | 8.8 |

| SZLH700 | 160 | 2.0-2.5 | 7.6 |

| SZLH760 | 160 | 1.5-2.5 | 9.6 |

| SZLH860 | 220 | 2.5-3.5 |

10 |

The final biomass wood pellet have the following charactures:

Pellet size: the size of the wood pellet could be 6/8/10/12mm(but the most popular sale is 6/8mm), you can change the pellet size through changing the mould.

Pellet lenght: The lenght of the flat die wood pellet machine could be 30-36mm(adjustable), and the best selling is 33mm.

The final wood pellets are up to European standard, and with smooth surface, high density, hard, it is hot selling in the world.

Applicable Material:

Applicable to: rice husk, sunflower seed shell, peanut shell and other melon shell; branches, trunks, bark and other wood scrap; all kinds of crop straw, rubber, cement, gray Slag and other chemical raw materials, etc.

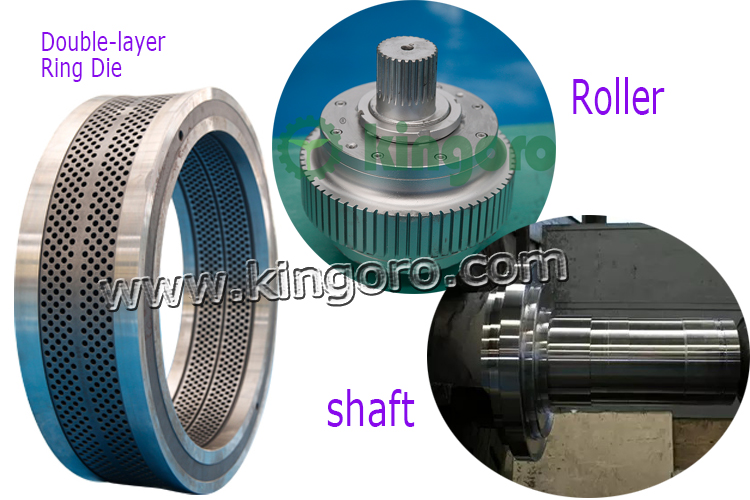

Wood Pellet Machine Details:

Customer Case

Our Company:

Shandong Kingoro Machinery was established in 1995 and has 23 years of manufacturing experience. Our company is located in beautiful Jinan, Shandong, China.

We can supply complete pellet machine production line for biomass material, include chipping, milling, drying, pelletizing, cooling and packing, according to different requirements of our customers. We also offer industry risk evaluation and supply suitable solution according to different workshop.

Kingoro as an advanced manufacturer of biomass pelletizers, owns 17 national patents and has obtained IS09001 quality system certification, CE certification, and SGS certification.

FAQ:

1.We need to know the following information to give a quote and solution

1)What is your raw materials? (to confirm mould pressure ratio of machines )

2) What is the moisture content of your raw material?

3)How many output capacity do you want per hour / month/ year?

Note: If the moisture is high, you need a dryer, becuase the suitable moisture content to enter pellet machine is 10-15%.

And please provide us above detailed information, then we would design the most suitable production line with reasonble offers.

2. Q: How long is your guarantee?

A: 12 months warranty but except quick wearing parts.

3. Q: Will you send engineers to install the machines?

A: Of course. Our company has professional installation engineers team and specialized after-sale service team.

When the machines arrive your factory, we will send our installation engineers to your factory

Our engineers will Guide you to install the machines and training your workers how to operate the machines and maintain the machine.

4. Q: Voltage requirement ?

A: Our machines can use 380V, 220V, 240V, 415V, 480V, and 50Hz, 60Hz.

Jinan, Shandong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Video

Send your inquiry to this supplier