1 / 6

CE and ISO 9001-2008 certificate qt12-15 block forming machine with strong vibratior

| Model No. : | QT12-15 |

|---|---|

| Brand Name : | Hongfa |

Product description

Hongfa Group--Shandong Hongfa Machinery Co., Ltd is a construction and building materials equipments manufacturer , Hongfa Group have 4 machine manufacturer Company, 39 branches all over the world. Mainly produce all kinds of concrete block making machine, AAC block making machine, concrete mixing plant, mixer, concrete tile making machine and concrete pipe making machine with more than 20 years experience and being the biggest manufacturer in China at present. All the products are conformity with the CE, ISO9001-2008, BV, TUV Internatinal certificate. CE and ISO 9001-2008 certificate qt12-15 block forming machine with strong vibratior

Hongfa Group--Shandong Hongfa Machinery Co., Ltd is a construction and building materials equipments manufacturer , Hongfa Group have 4 machine manufacturer Company, 39 branches all over the world. Mainly produce all kinds of concrete block making machine, AAC block making machine, concrete mixing plant, mixer, concrete tile making machine and concrete pipe making machine with more than 20 years experience and being the biggest manufacturer in China at present. All the products are conformity with the CE, ISO9001-2008, BV, TUV Internatinal certificate. CE and ISO 9001-2008 certificate qt12-15 block forming machine with strong vibratior (1)Main Technical Parameter

| Dimension | 9350*2520*2950mm |

| Rated pressure | 21MPa |

| Main vibration form | Platform vibration |

| Molding cycle | 12-25s |

| Acceleration of vibration | 15-20g |

| Vibration frequency | 4800r/min |

| Exciting power | 695KN |

| Pallet size | 1300*900*30mm |

| Overall power | 44kw |

| Applied products | concrete blocks, solid/hollow/cellular masonry products, paving stones with or withour face mix, garden and landscaping prodcuts, slabs, edgers, curbstons,grass blocks, slope blocks, interlocking blocks, etc. |

| Raw Materials | crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, expanded perlite, and other industrial wastes |

| 1,It adopts PLC intelligent control. and Control system is equipped with complete logic control, production program, malfunction diagnosis system and remote control function. So it doesn’t need a professional person to be the operator. |

| 2,Particular storage and discerption material system insure the feeding accuracy and avoiding the effect of exterior material. So the products have high density. |

| 3,Using unique synchronous mechanism,which can effectively assure the mould box consistent with the height of brick around it; Scientific vibration system to ensure transmitted vibration force to each part of the mould box in equality,achieve materials’ feeding quickly and shorten molding cycle |

| 4,Imported electrical appliances and hydraulic pressure components to ensure the equipment stably working; Industrial computer deposits dozens of production formulas for users to choose. |

1) Photos of main machine with details

1) Photos of main machine with details  2) Some of main equipments for production line

2) Some of main equipments for production line  3) This machine can make all kinds of blocks by changing mould

3) This machine can make all kinds of blocks by changing mould

5)Three factories assure mass production of timely shipment capacity and excellent after-sales service

5)Three factories assure mass production of timely shipment capacity and excellent after-sales service  6) Exquisite techniques with reliable quality assurance

6) Exquisite techniques with reliable quality assurance 7) Products can be certificated by ISO, SGS,BV,CE or others third-party testing organizations.

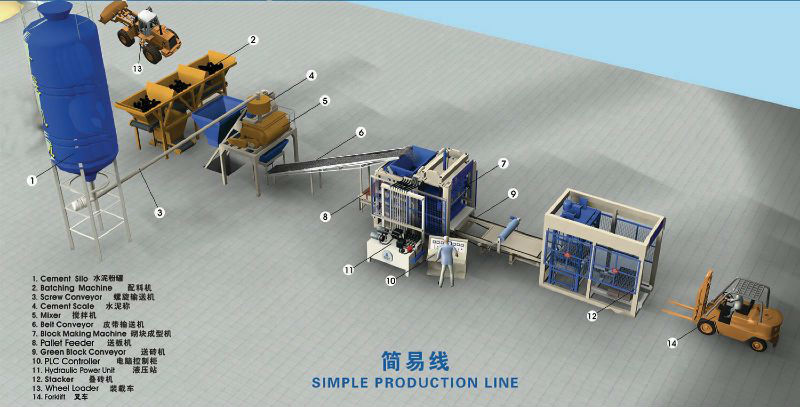

7) Products can be certificated by ISO, SGS,BV,CE or others third-party testing organizations.  Option A: Simple Production Line:

Option A: Simple Production Line:  Option B: Full-automatic Production Line

Option B: Full-automatic Production Line  Packaging & Shipping Shandong Hongfa Machinery has won many honors through outstanding products and advanced technology and we always see product quality as life and customers as god. We has set up good service philodophy: timely repair the equipment when it breaks down, provide project design and production flow designing for the customers, formulate the equipment purchase plan for the customers, provide high-quality products,provide considerate customer training, timely and effectively repair the fault of the equipment and test and sovle the difficult processing problems for the customers. Pre-sale service support: According to each customer's demand and budget, we offer you the professional solution, process flow design and production equipment. More importantly, we welcome every customer to visit our factory and working machine in the site before placing the order. We will arrange cars, hotels and translators for the visiting customers. During-sale service support: Assist clients to finish the factory planning. Before delivery equipment to customer s, complete debugging and checking. Provide a full instruction manual for the whole system. Provide technical guidance for the installation and use of the unit, including installation advice and electrical connection. Provide unit debugging and training for the operation of the machine on the working site and coordiante the customers with check and acceptance of the unit. After-sale service support: Send technicians to installation site for the guidance, equipment adjustment and training. Provide high-quality spare parts thoughout the year, and the maintenance technicians are always ready to provide technical help. FAQ Warmly welcome to call us, email us, cooperation and selection of quality products,

Packaging & Shipping Shandong Hongfa Machinery has won many honors through outstanding products and advanced technology and we always see product quality as life and customers as god. We has set up good service philodophy: timely repair the equipment when it breaks down, provide project design and production flow designing for the customers, formulate the equipment purchase plan for the customers, provide high-quality products,provide considerate customer training, timely and effectively repair the fault of the equipment and test and sovle the difficult processing problems for the customers. Pre-sale service support: According to each customer's demand and budget, we offer you the professional solution, process flow design and production equipment. More importantly, we welcome every customer to visit our factory and working machine in the site before placing the order. We will arrange cars, hotels and translators for the visiting customers. During-sale service support: Assist clients to finish the factory planning. Before delivery equipment to customer s, complete debugging and checking. Provide a full instruction manual for the whole system. Provide technical guidance for the installation and use of the unit, including installation advice and electrical connection. Provide unit debugging and training for the operation of the machine on the working site and coordiante the customers with check and acceptance of the unit. After-sale service support: Send technicians to installation site for the guidance, equipment adjustment and training. Provide high-quality spare parts thoughout the year, and the maintenance technicians are always ready to provide technical help. FAQ Warmly welcome to call us, email us, cooperation and selection of quality products,  Promise ·Welcome to our website,you will find your best like styles! ·Wanna you see,just wanna you do now! ·Your satisfaction is necessary to our success. ·Our goal is to provide you with the best level of customer s

Promise ·Welcome to our website,you will find your best like styles! ·Wanna you see,just wanna you do now! ·Your satisfaction is necessary to our success. ·Our goal is to provide you with the best level of customer s Send your inquiry to this supplier