1 / 5

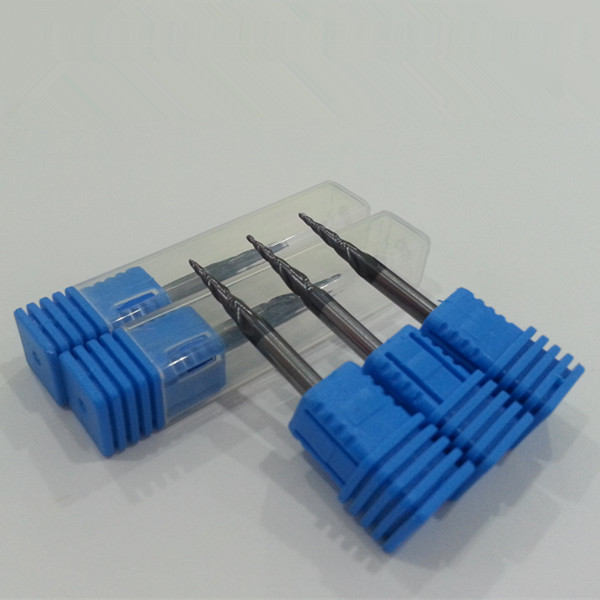

Carbide Taper Ball nose end mill

| Model No. : | X-JF16813-0045-45 |

|---|---|

| Brand Name : | XTJF |

| Diameter : | 4 |

Product description

Solid Carbide Mills

|

Milling Model Name |

Machining material and/or rigidity |

V(m/min) |

Fz(mm/z) |

Ap(mm) |

Aw(mm) |

|

Solid carbide key way milling tools |

Steel HB 180-280 |

70-150 |

0.01-0.06 |

0.4-0.6D |

<=D |

|

Cast-iron HB 180-220 |

100-120 |

0.01-0.06 |

|||

|

Solid carbide end mills,corner rabius end millstaper enn mills |

Steel HB 180-280 |

90-160 |

Milling flutes0.01-0.01 |

Milling flutes<=D Side milling<=1.5D |

Milling flutes<=D Side milling<=0.2D |

|

Side milling0.03-0.3 |

|||||

|

Cast-iron HB 180-220 |

100-150 |

Milling flutes0.02-0.15 |

|||

|

Side milling0.06-0.45 |

|||||

|

Solid carbide ball head end mills |

Steel HB 180-280 |

80-220 |

0.01-0.08 |

<=0.4D |

<=D |

|

Cast-iron HB 180-220 |

280-280 |

0.02-0.10 |

|||

|

Solid carbide taper ball head end mills |

Steel HB 180-280 |

120-170 |

0.01-0.08 |

||

|

Cast-iron HB 180-220 |

250 |

0.02-0.10 |

1. Specifications

-solid carbide taper ball nose end mills

- Up to: HRC60-65 high speed

- Super-fine micro grain carbide rod: WC=87.5%, Co=12.5%, TRS>4200N/mm2; Hardness>92.5HRA

- Grain size: 0.4-1 um

- Chemical composition: 10%-12%Co-WC

- Density: 14.10-14.45g/cm3

- Hardness: 91.5-92.5HRA

- Flexural strength: 3500-4000N/mm2

- Working material for steel and high speeding cutting;

- Any your drawings design are acceptable;

2. Raw Materials

- SANDVIK of Sweden;

- Teagutec of Korean;

- Kennametal of American;

- Guhring of Germany;

- YG10X of Zhuzhou China;

- WC25F of Taiwan;

3. Our Workshop and Advanced Equipments

- Walter CNC machine from Germany;

- ANCA CNC machine from Australia;

- Guhring detecting instrument from Germany;

- MICHEAL DECHAL CNC Machine from Germany;

4. Our advantages:

- Our carbide end mills are made by 5 Axi grainding machine with high toughness & high wearing precision;

- Our carbide end mills have long usage life lasting in hardened steels,

- Every product will inspected by Zoller Machine;

- Special CNC solid tools with high quality/ometitive price/good service;

5. Package

- One piece in one plastic box, and ten boxes in one carton;

- Any other requested packing are acceptable;

6.Maching Parameter Guidelines

1. The discharge of chips and rigidity of tools by the number of the flutes

The number of the flutes is essential part of the performance of end mills. Generally , if there

Are few flutes, it is easy to discharge of chips but relatively section areas get smaller so that

it makes the rigidity of tools fall down and enable tools to sway on cutting . On the other hand,

if there are many flutes , the section areas get larger and rigidity gets higher but the chip capacity

goes down owing to lessened the chip pocket and it is easily blocked up by chips.

2. The rigidity of tools by the length of the flute

The shorter of the tools, the higher the rigidity and performance of cutting. The length of the flute

become twice, the rigidity of the end mills falls to 1/8.Because end mills are the tools to move horizontal,

it is important for the rigidity of tools to be in inverse proportion to the length of tools. Using a longer flute

that need be is not good.

You can choose suitable flutes for your cutting conditions.

Send your inquiry to this supplier