Video

1 / 6

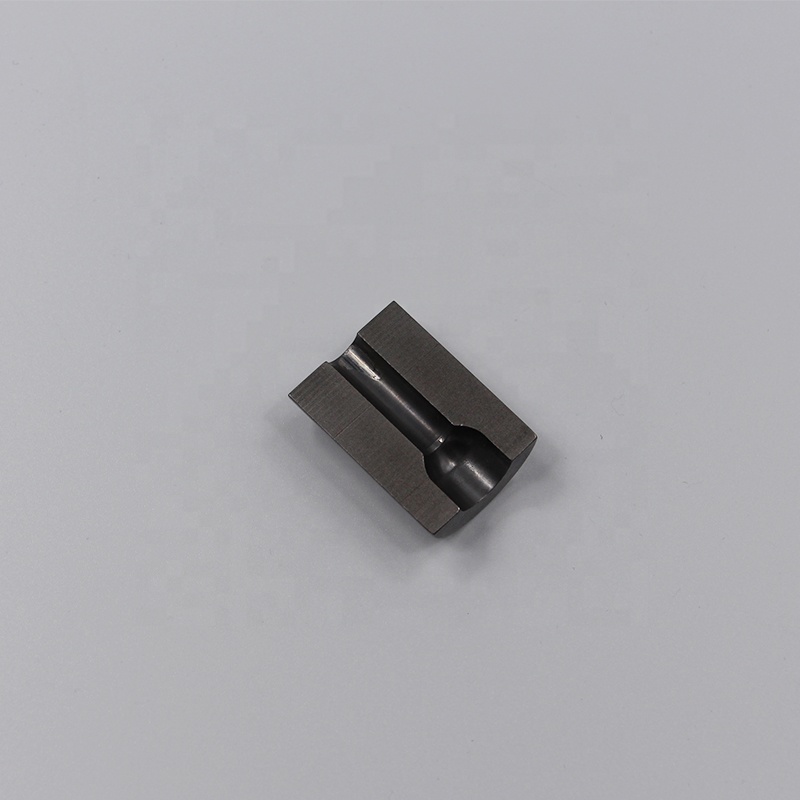

Carbide Cold Heading Dies High Strong Beam Die

Options:

- Customized

| Brand Name : | Henghui |

|---|

Product description

Carbide Cold Heading Dies High Strong Beam Die Carbide Shaped Forming Dies

Product introduction

Henghui’s extrusion dies, Different carbide grades in order to improve tool performance. Extrusion dies for easy removal and replacement of it using the same casing.

Accurate concentricity.

This is one of the most important parameters. It guarantees that the wire will be perfectly centered within the insulation material. This tight tolerance (0.0025mm / .0001”) is one of the keys in the quality of our tools.

Marking area

High definition laser marking area with diameter and other important customer details (upon client request).

Henghui has developed its own state-of-the-art technology in order to improve tools’ lifespan whilst keeping costs down.

This die design technology allows the use of interchangeable carbide die on the working area. On extrusion dies, a well-polished surface is essential,the polishing is done before can extending the tool’s lifespan.

We will suggest:

The selection of cemented carbide materials.

PVD, different coatings to be applied depending on the extruded material.

Mature polishing technology

Henghui's Tungsten Carbide Dies are designed with high precision in order to meet the international quality standards. We offered dies are known for their robust designs, professional processing and longer service life.Tungsten Carbide Dies can be used in the production of fasteners and can also be applied to other industries.Apart from this, the offered tungsten carbide dies are available in various sizes and dimensions as per the varied needs of the clients.

|

FAQ

Q1:Are you a factory or trading company?

A1:We are a factory, Henghui has 7,00 square meters of manufacturing plants and R&D bases.

Q2:Where is your factory located? How can I visit there?

A2:Our factory is located in Hailong Village, Baishiyi Town, Jiulongpo District, Chongqing City, China. All our clients, from home or abroad, are warmly welcome to visit us at anytime!

Q3:What is the material of your products?

A3:The material is ST7,VA80,G6,H13(SKD-61), or as our clients’ requirements.

Q4: The maximum press your factory have available ?

A4: Our factory has 30T,60T,160T punching machines.

Q5::How does your factory do regarding quality control?

A5: Quality is priority.We always attach great importance to quality controlling from the very beginning to the very end.

Why Choose Us:

|

Video

Send your inquiry to this supplier