1 / 6

C-type Hydro Pneumatic Press Machine Of Single Column , 100t / 200t

Product description

C-Type Hydro Pneumatic Press Machine Of Single Column , 100T/200T

Quick Detail:

- Hydraulic straightening and mounting press machine

- C type single column structure press machine

- Cold or heat hydraulic oil press machine

- Adopted hands operation and foot pedal

- Apply to industry of machine tool, power engine, axle, bearing, washing machine, plastic product, powder molding, electric and etc.

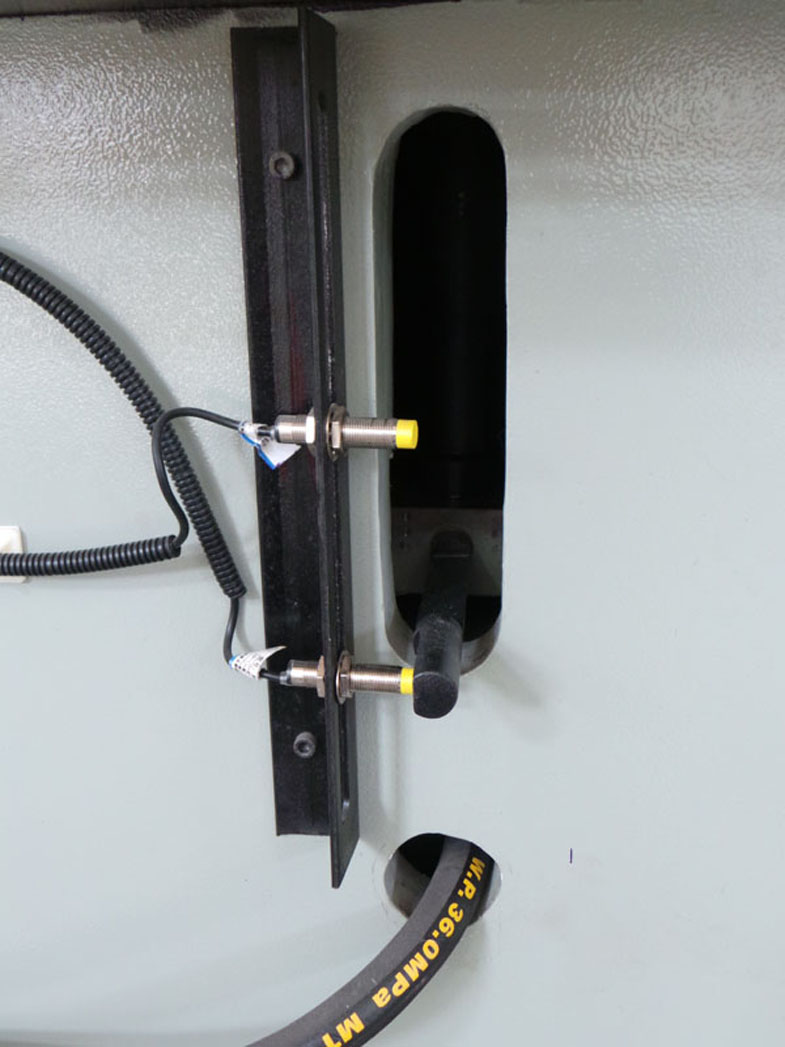

- Equipped displacement sensor and digital display system.

- Hydraulic press model are from 2.5 ton,6.3 ton,10 ton, 40 ton,63 ton, to 100 ton.

Specifications:

|

Type |

Unit |

2.5T |

6.3T |

10T |

16T |

25T |

40T |

63T |

100T |

|

|

Nominal pressure |

KN |

25 |

63 |

100 |

160 |

250 |

400 |

630 |

1000 |

|

|

Max. pressure of liquid |

Mpa |

4.9 |

12.5 |

8.1 |

13 |

20.3 |

23 |

18.5 |

25 |

|

|

Max. opening height |

mm |

300 |

450 |

500 |

600 |

600 |

700 |

800 |

800 |

|

|

Max. stroke of slider |

mm |

160 |

250 |

300 |

350 |

350 |

400 |

500 |

500 |

|

|

Downstream speed of slider |

mm/s |

60 |

85 |

85 |

110 |

110 |

85 |

85 |

85 |

|

|

Working speed of slider |

mm/s |

Adjustable range: 7—15 |

||||||||

|

Return speed of slider |

mm/s |

120 |

120 |

120 |

120 |

120 |

120 |

120 |

120 |

|

|

Throat depth |

mm |

200 |

200 |

225 |

225 |

225 |

300 |

350 |

350 |

|

|

Shank hole size |

mm |

Ø20 |

Ø20 |

Ø25 |

Ø25 |

Ø30 |

Ø30 |

Ø40 |

Ø40 |

|

|

Table size |

F.B. |

mm |

400 |

380 |

420 |

420 |

425 |

550 |

650 |

650 |

|

L.R. |

mm |

400 |

480 |

500 |

500 |

550 |

600 |

700 |

700 |

|

|

Operation height |

mm |

900 |

750 |

750 |

750 |

750 |

700 |

715 |

715 |

|

|

Blanking aperture |

mm |

70 |

80 |

80 |

100 |

100 |

80 |

100 |

100 |

|

|

Power of motor |

KW |

2.2 |

2.2 |

2.2 |

3 |

4 |

4 |

5.5 |

5.5 |

|

|

Overall dimension |

F.B. |

mm |

900 |

900 |

1100 |

1100 |

1100 |

1350 |

1530 |

1530 |

|

L.R. |

mm |

730 |

730 |

960 |

960 |

960 |

1000 |

1600 |

1600 |

|

|

Above floor |

mm |

1800 |

1910 |

2200 |

2300 |

2300 |

2700 |

2900 |

2900 |

|

|

Total weight |

Kg |

800 |

1200 |

1500 |

1750 |

2500 |

3700 |

3700 |

4000 |

|

Configurations of main components:

|

Name |

Brand |

Configuration |

Name |

Brand |

Configuration |

|

Circuit Breaker |

Schneider, France |

S |

Security Light Curtain |

SENSORC, China |

S |

|

Thermal Relay |

Schneider, France |

S |

Motor |

Quality product, China |

O |

|

Intermediate Relay |

Schneider, France |

S |

Oil Pump |

Quality product, Taiwan |

O |

|

Power Source |

Schneider, France |

S |

Hydraulic Valve |

Tian Li, Beijing |

O |

|

Button |

Schneider, France |

S |

Sealing Element |

NOK, Japan |

S |

|

Time Relay |

SIEMENS, Germany |

S |

PLC |

MITSUBISHI, Japan |

O |

|

Transformer |

Bright, Wuxi |

S |

TPC |

MCGS, China |

O |

Notes: S stands for standard configuration, and O stands for optional configuration

Description:

- YSK Series C-type Pressure Test Hydraulic Press is a kind of machine which tests pressure with NC. It is suitable for the press fitting of shaft components and axle sleeve parts.

- with a pressure sensor on the hydraulic, through the data collection and systematic treatment done by a micro computer, turning into arber force value and makes digital display.

- When the limited time reached, it will give an acousto optical alarm and a signal for stopping the machine tool, so that to reach the aim for controlling the machine tool automatically.

- The load-display-control-led displays clearly, with accurate control, instant response, reliable operation and can be replacedwith different sensors and application software used for forging equipments with different tonnages.

- The application of counter let every operation know the sum total and the number for unqualified. With double pressed bottoms increased, the operation of the machine tool becomes safer.

- It is suitable for the press fitting of plasticity material and powder product; the straightening of shaft components and axle sleeve parts; the press fitting of electrical components; the stretch of small plate-shaped parts; molding blanking; coining and overprinting.

- It operates with hand.

Applications:

- This machine tool is a kind of processing equipment used in the fields of motor-washing machine and various of sleeves and bearings with strong suitability.

- C-frame design for large operating spaces - suitable for automatic operations forming, punching, bending, straightening and multi-press assemblies to form automatic production line.

Elecctrical Diagrams

Mitsubishi PLC

TPC

Siemens Motor

Rexroth Valve

Competitive Advantage:

1. CE, ISO Certification.

2. We can supply KLT brand or OEM for clients.

3. We can supply product line solution according to clients’ requirements.

4. Independent electrical control with PLC and TPC.

5. Adopted Rexroth Hydraulic valve system/Siemens Motor to ensure that the hydraulic system is not leaking.

6. The pressure, stroke, and time of pressure maintaining can be regulated.

7. High quality and performance with good price.

8. Safe and stable operation.

9. Support 7*24 remote service or locate service.

10. Supply maintenance service all life.

Send your inquiry to this supplier