1 / 5

BF Flotation Machine Tin Ore Flotation Machine

| Model No. : | BF-0.25 |

|---|---|

| Brand Name : | Henghong |

| After-sales Service Provided : | Engineers Available To Service Mac |

Ganzhou, Jiangxi, China

- Manufacturer

- Service

- Trade Company

- OEM service

- Platform Certification

Product description

Description

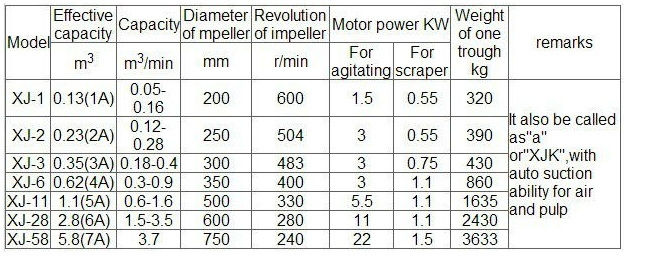

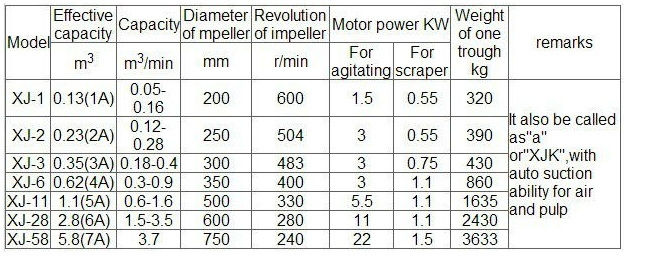

1, this machine is a mechanical flotation machine impeller.

2, the machine is mainly composed of a slurry tank, a stirring device, charging device, discharge device, motor and other components of mineralized bubbles.

(1): a slurry tank: it has a pulp inlet, as well as the regulation of the pulp side gate device, which is mainly composed of a tank body and welded by steel plate steel plate and steel welding gate.

(2): it is used for mixing slurry stirring device, to prevent the sand in the tank to precipitate, which is mainly composed of a belt wheel, impeller, vertical shaft etc, the impeller is made of wear-resistant rubber.

(3): inflatable device: it consists of a catheter into the pipe, when the impeller rotates, the impeller cavity to generate negative pressure, the air through the hollow tube of the pump suction, and diffusion in the pulp to form bubble group, with the large bubble slurry by the impeller rotation force and is soon thrown to the stator, further so that the pulp the air bubble fining, and eliminate the flotation tank of pulp flow rotary motion, resulting in a large number of vertical upward microbubble flotation process, to provide the necessary conditions.

(4): removal of mineralized bubbles device: it is floating in the groove surface of the foam scraping, mainly driven by a motor, reducer, reducer drives the scraper.

Method and principle

The ground ore, in the ground or ground water and the necessary agent stirring trough into pulp, the pulp tank into the mix, to the pulp into the air, so that the formation of large bubbles, are not easy to be wetted by water, which is generally called hydrophobic mineral particle attached to the bubbles, and the bubbles float to the surface together with pulp, the formation of mineralized bubble layer, some easy to be wetted by water, which is generally called hydrophilic mineral particles is not attached to the bubbles, while remaining in the pulp

Pre-sale service:

We will provide you with the prior plan, process flowchart design and production equipment in line with your special needs.

Sale-service:

We will send technicians to you for guiding the equipment installation, commissioning and staff

training.

After-sale service:

We will regularly pay return visit to customers for establishing a long-term and friendly relationship.

All machines have one year warranty to make sure your machine work well.

Warmly welcome you come to visist our factory

Our factory located at Ganzhou city, Jiangxi province, China.

Visit line: Take flight from your country to Guangzhou airport in China, and then take flight from Guangzhou to Gan zhou airport, then we will send the car to pick you up from Ganzhou airport.

Contact Person: Iris Huang

Mobile: 008618870736160

Pre-sale service:

We will provide you with the prior plan, process flowchart design and production equipment in line with your special needs.

Sale-service:

We will send technicians to you for guiding the equipment installation, commissioning and staff

training.

After-sale service:

We will regularly pay return visit to customers for establishing a long-term and friendly relationship.

All machines have one year warranty to make sure your machine work well.

Warmly welcome you come to visist our factory

Our factory located at Ganzhou city, Jiangxi province, China.

Visit line: Take flight from your country to Guangzhou airport in China, and then take flight from Guangzhou to Gan zhou airport, then we will send the car to pick you up from Ganzhou airport.

Contact Person: Iris Huang

Mobile: 008618870736160

Ganzhou, Jiangxi, China

- Manufacturer

- Service

- Trade Company

- OEM service

- Platform Certification

Send your inquiry to this supplier