1 / 5

Best selling twin shaft mixer machine for feed powder with CE for sale

| Model No. : | SLHS Series |

|---|---|

| Brand Name : | Shuanghe |

Product description

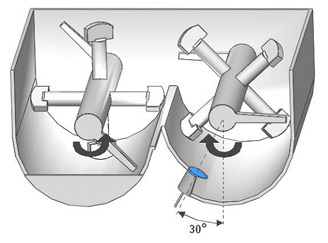

Dual-shaft oar efficient mixer machine is constituted by twin screw and atomizing system. The filling seal is adopted for ends of shaft to improve tightness and prevent from leakage.It has compact structure long time use.It can mix difference material like foodstuff and other materials.It has voltage of 380.Mix time is 5-8min,the evenness can reach more than 95%.It can work with crusher and pellet mill.

Range of application:

This feed mixer can not only be used for the crusher of pellet fodder but also soybean, corn and soft materials. Various liquids can be added.Mixing time is short(40-60seconds/group),and the coefficient of variation is low(CV<5%).Full-opened structure makes no material left,and the output speed is fast.It is suitable for premix material blending applied to the professionals such as poultry,aquatic feed,chemical industry and so on.

Main performance characteristic:

a.Double shaft paddle mixer ,mixing powder to

powder, particle to particle or particle to powder ,liquid can spay into

material ,but all material must be solid powder during all the process.

b.The two axes rotate

at the same speed with different direction, it can mix material uniformly with

1:1000 proportion, or with great different of density.

c.When mixing, by

suffering great power of interaction , it will cause material destroyed at very

small scope

d.When mixing, the

materials are moving at enormous energy, it will request the machine must have

enough power.

e.The gap between the

paddle and cylinder wall is 3~5mm, so to enforce the mixing effect and reduce

the leftover after discharge.

Note:

1.High effective and Low consumption

2.Professional manufacturer

3.Continue working long time

4.low-speed with screw, low motor

5.Mixing time(min):4-6

6.Operation speed low,mixing efficiency high,and moving is gentle.

|

Model |

SLHSJ 0.5(Stainless) |

SLHSJ 1 |

SLHSJ 2 |

SLHSJ 4

|

SLHSJ 1(Stainless) |

|

Power(kw) |

7.5 |

11 |

18.5 |

30 |

11 |

|

Volume(L) |

0.25 |

0.5 |

1 |

2 |

0.5 |

About service:

1. We take customers as our gods. We devote to

all-round service of all the products from shipment to maintenance.

2. Our professional service includes: Free training,

guidance, installation, and debugging.

3. After selling, we provide the warranty of one year.

4. If you have any problems, we will help to solve on

line or live in time.

5. Authorized oversea agents are also engaged in serving.

Our products have CE certificate, and have

passed ISO9001. So they are of good quality and good price.

Thank you for your reliance and support. We'

ll do our best to accomplish your sincere requirement. If you are interested in

our machine, please contact me.

Send your inquiry to this supplier