1 / 5

Ready Mix Concrete Batching Computer Systems

| Model No. : | HZS |

|---|---|

| Brand Name : | We need it for you all |

| Type : | Concrete Mixing Plant |

Harbin, Heilongjiang, China

- Manufacturer

- Trade Company

- Platform Certification

- SGS Certification

- Online Expo

Product description

Ready Mix Concrete Batching Computer Systems

Product description

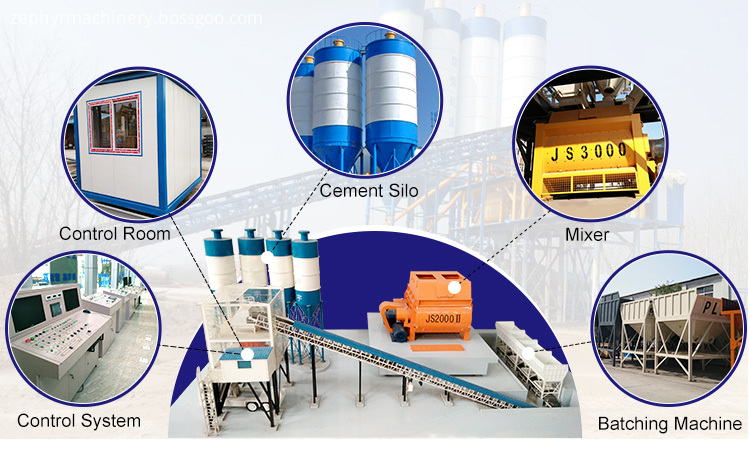

Ready mix concrete batching plant 60m3 h belt conveyor concrete batching plant is widely used in big ormedium building projects,road and bridges projects, precastconcrete plants,etc.It is an ideal choice for producing commercialconcrete. It has two feeding methods. One is hopper type, it is used for lower than 50m3 per hour output production. The other is belt type, it is often used for higher than 60m3 per hour outputproduction. For export, we adopt full automatic control system for our stationary concrete mixing plant. It is PC+PLC control, which can vividly display the production process on the screen, so that the operator can monitor in real time.

Features of Belt Conveyor Concrete Mixing Plant

1, Adopts combined type structure and modularized units, very convenient for assembly, disassembly and transport. With various layout forms to adapt with different sites.

2, Adopts JS1000 forcing type twin shaft horizontal mixer, assures good mixing quality and high working efficiency. Realize good mixing quality in a short time for dry concrete, half dry concrete, plastic concrete and other concrete with different ratios.

3, All weighing and control components are imported with good quality, mircocomputer control, assures accurate weighing and reliable performance.

4, Powdery materials are processed in hermetic condition in all procedures including loading, batching, weighing, charging, mixing and discharging. There is a high quality dust remover in the main mixing pot, also the mixing pot and belt conveyor are sealed. Vastly reduced dust and noise pollution, environment friendly.

5, Platform or ladders are equipped for every maintainence positon, high-pressure pump washing equipment is also equipped.

6, Duplex computer control system, continuous and fluent operation while switching. Dynamic panel display shows operation of every part clearly. Visualized monitoring interface provides clear observation. Report printing function.

7, Electronic control system adopts imported high quality components, reliable and powerful performance. Fault automatic diagnosis, alarms with characters, voice and light, convenient for malfunction elimination.

Technical Parameters of Belt Conveyor Concrete Mixing Plant

Model

HZS60

HZS90

HZS120

HZS180

Global parameter

productivity(m3/h)

60

80

100

150

Discharging height(m)

3.8

3.8

3.8

3.8

Feeding volume(L)

1600

2400

3200

4800

Discharging volume(L)

1000

1500

2000

3000

Total power(Kw)

92

108

127

178

Mixer

Model

JS1000

JS1500

JS2000

JS3000

Batcher

Model

PL1600

PL2400

PL3200

4800

Cement Silo

Model

SNC100

SNC100

SNC100

800

Measurement system

Aggregate weighing capacity (Kg)

3500

4500

6000

800

Cement weighing capacity (Kg)

600

1000

1200

50

Fly ash weighing capacity (Kg)

300

300

500

2*55

Water weighing capacity (Kg)

300

500

600

±2%

Additives weighing capacity (Kg)

30

30

50

±1%

Mixing power(Kw)

2×18.5

2*30

2*37

±1%

Measuring precision(%)

Aggregate

±2%

±2%

±2%

±1%

Water

±1%

±1%

±1%

±1%

Cement

±1%

±1%

±1%

±1%

Additives weighing capacity (Kg)

±1%

±1%

±1%

±1%

Packaging&Shipping of Our Products

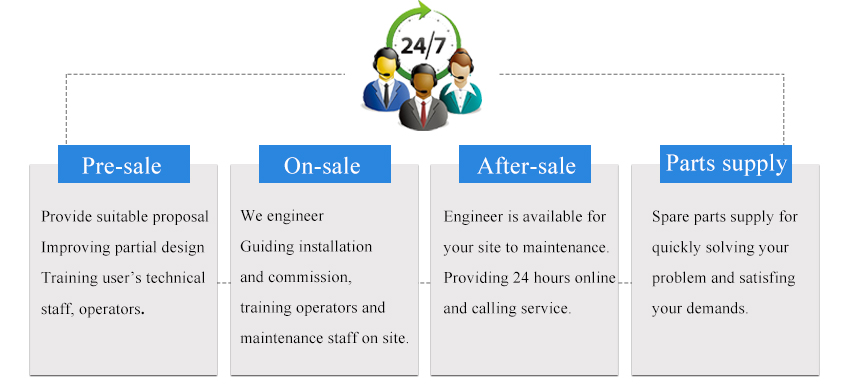

Our Service

1.According to your inquiry, the first time to give the offer, the first time to give production.

2.Best After-sales: We will send the technical personnel to the site for installation, commissioning and training work.

3.Warranty period 12 Months, in addition to the force majeure and man-made factors, the damage caused by design, process and manufacturing equipment, the seller is responsible for sending people to offer free repair.

4.We will send the spare parts of concrete mixer plant as soon as possible when necessary, equipment repair parts provided by the seller are original, authentic, quality goods.

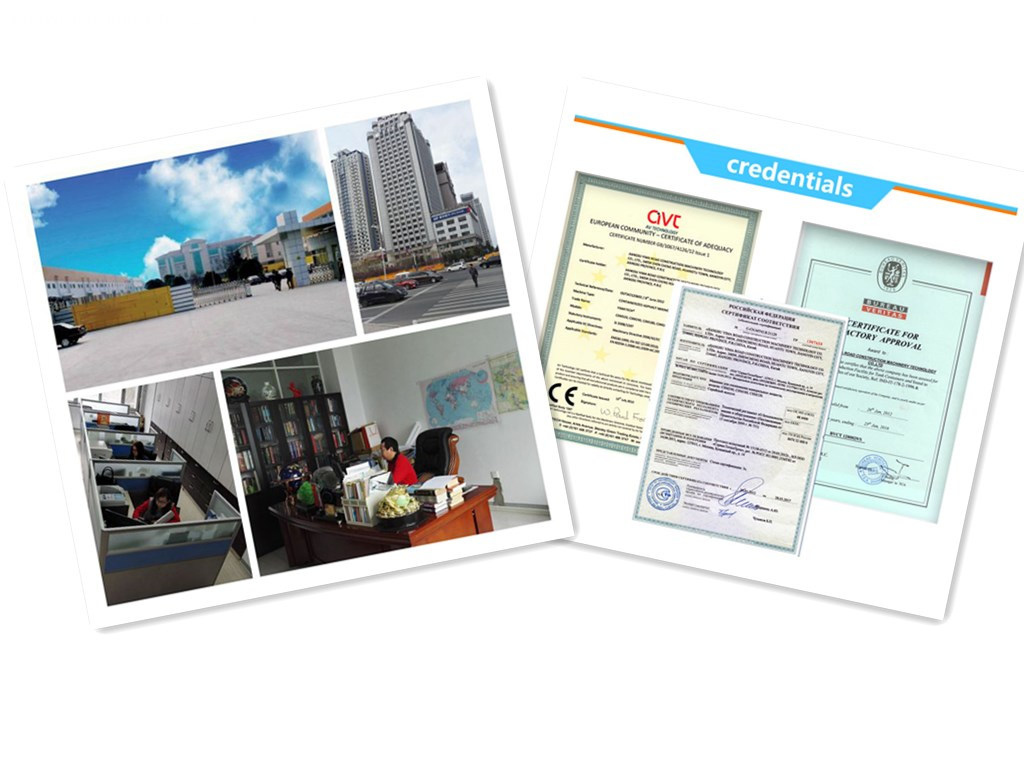

Harbin Zephyr Trading Co.,Ltd locates in the north of China, province Heilongjiang,city Harbin.This is an international trading company mainly exports large road machinery such as:asphalt mixing plant,concrete mixing plant,crushing and screening production line and Excavator,Loader,Bulldozer,Truck crane,Concrete mixer truck and so on...

As one of the first professional supplier of asphalt mixing plant and concrete mixing plant in China,we have always given attention to maintaining our higher level quality control and service , and we have received the ISO9001,CE,SGS etc certificates.Our equipment has exported to 35 countries,including:Russia,India,Bangladesh,Ghana etc.

If you have any inquiry about the concrete mixing plant or constructions machinery,please fell free to contact us,We are always warmly welcome you to come and look forward to our meeting!

FAQ

Whar 's your after-sale service?

1, 12 months warranty from products departure. Enough spare parts and quick-wear parts sent together.

2, Onsite installation, debugging, workers training. Make sure that your workers operate properly and know daily maintenance well.

3, Prompt reply in case of any problems.

What`s the service life of your machinery?

Usually 5-10 years under good maintenance.

How soon can you reply me?

In 1 working day, detailed quotation and program design will be offered.

What`s your delivery time?

5 days for single machines, 15 days for plants.

What are your payment terms?

T/T, L/C, Paypal, Credit card, Western union, Moneygram are all ok.

Can you customize by my specialized request?

Yes, we can.

Contact Us

If interested in our products, please contact with us without hesitation.

We are waiting for your message. ↓↓↓

Harbin, Heilongjiang, China

- Manufacturer

- Trade Company

- Platform Certification

- SGS Certification

- Online Expo

Send your inquiry to this supplier