1 / 6

Ball Mill Manufacturers Dry or Wet Ball Mill/Open Circuit Grinding Ball Mill

| Model No. : | various |

|---|

Product description

Open Circuit Ball Mill Advantages

1. Less easy wear parts,

2. Long history, have sold to many countries, got CE CERTIFICATE

3. Mining Ball Mill, Grinding ball mill, milling machine, ball mill

Open Circuit Ball Mill with ISO9001: 14000

Ball mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many kinds of mine and other materials, or to select the mine. Ball mill is widely used in building material, chemical industry, etc. And ball mill have two ways of grinding: The dry process and the wet process. Ball mill can be divided into tabular type and flowing type according to different forms of ball mill's discharging material.

Ball Mill's Importance and Value

Ball mill is a key equipment for regrinding. Ball mill is widely used for the cement, the silicate product, new type building material, fire-proof material, chemical fertilizer, black and non-ferrous metal, glass, ceramics and etc. Our ball mill can grind ore or other materials that can be grinded either by wet process or by dry process.

Open Circuit Ball Mill Working Principle:

This ball mill is horizontal type and tubular running device, our ball mill has two warehouses. This machine is grid type and ball mill's outside runs along gear. The material enters spirally and evenly the first warehouse of the milling machine along the input material hollow axis by input material device. In this warehouse, there is a ladder scaleboard or ripple scaleboard, and different specification steel balls are installed on the scaleboard, when the barrel body rotates and then produces centrifugal force. Meanwhile, the steel ball is carried to some height and falls to make the material grinding and striking. After grinded coarsely in the first warehouse, the material then enters into the second warehouse for regrinding with the steel ball and scaleboard. In the end, the powder is discharged by output material board andthe end products are completed.

Open Circuit Ball Mill Features and Benefits:

This ball mill is made up of feeding part, discharging part, gyre part, transmission part, (decelerator, small transmission gear, generator, electrical control ) and so on. The hollow axis adopts the cast steel and the lining can replace, the rotating big gear processes in the way of casting rolling gear. The barrel body is wearable well and bears wearable scaleboard. This ball mill run steadily and works reliably.

Process Of Open Circuit Ball Mill's Grinding:

Ball Mill grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be ground. The rotation is usually between 4 to 20 revolutions per minute, depending upon the diameter of the mill. The larger the diameter, the slower the rotation. If the peripheral speed of the mill is too great, it begins to act like a centrifuge and the balls do not fall back, but stay on the perimeter of the mill. The point where the mill becomes a centrifuge is called the "Critical Speed", and ball mills usually operate at 65% to 75% of the critical speed.

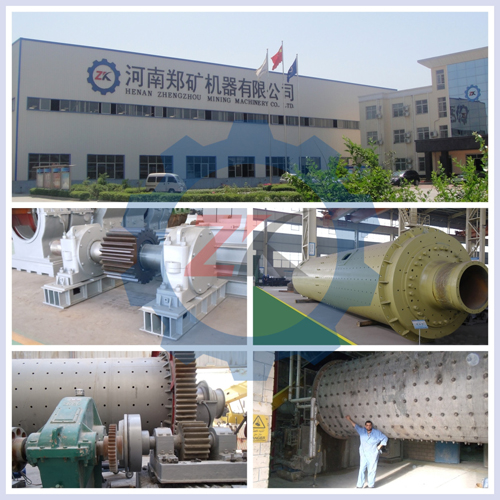

Company Name: Henan Zhengzhou Mining Machinery Co., Ltd.

Official Website: http://www.inczk.com/ & http://www.zkcomp.com/

24-hour Free Sales Consulting Phone : 861-0371 -5590 2866 .

Company Address: Qiaolou caizhai industrial estate, Xingyang city, Henan Province

Please pay attention to the company's other products:

Price of rotary kiln: http://www.zkcomp.com/calcining/558.html

Rotary Kiln:http://www.inczk.com/Products/459.html

Preheater:http://www.zkcomp.com/calcining/605.html

Cement Mill:http://www.inczk.com/Products/460.html

Rotary Dryer:http://www.zkcomp.com/calcining/564.html

Raw Mill:http://www.inczk.com/Products/1373.html

Ball Mill:http://www.zkcomp.com/grinding/582.html

| Specification mm | Drum Rotary Speed r/m | Ball Loading t | Feeding Granularity mm | Discharging Granularity mm | Output t/h |

Motor Power kw | Weight t |

| 900× 1800 | 38 | 1.5 | ≤ 20 | 0.075-0.89 | 0.65-2 | 18.5 | 3.6 |

| 900× 2400 | 38 | 2.7 | ≤ 20 | 0.075-0.89 | 1.1-3.5 | 18.5 | 4.1 |

| 900× 3500 | 38 | 2.7 | ≤ 20 | 0.075-0.89 | 1.1-3.5 | 22 | 4.6 |

| 1200× 2400 | 32 | 4.8 | ≤ 25 | 0.075-0.6 | 1.5-5.8 | 45 | 12.5 |

| 1200× 4500 | 32 | 6 | ≤ 25 | 0.074-0.4 | 1.6-6 | 55 | 12.8 |

| 1500× 3500 | 32 | 7 | ≤ 25 | 0.074-0.4 | 1.6-5.8 | 75 | 13.8 |

| 1500× 3500 | 32 | 7 | ≤ 25 | 0.074-0.4 | 1.6-5.8 | 75 | 13.8 |

| 1500× 5700 | 27 | 15 | ≤ 25 | 0.074-0.4 | 3.5-6 | 90 | 24.7 |

| 1830× 3600 | 24 | 11 | ≤ 25 | 0.074-0.4 | 4-10 | 155 | 28 |

| 1830× 6400 | 24 | 23 | ≤ 25 | 0.074-0.4 | 6.5 | 210 | 36 |

| 1830× 7000 | 24 | 25 | ≤ 25 | 0.074-0.4 | 7.5 | 245 | 38 |

Send your inquiry to this supplier