1 / 6

Axial Split Case Double Suction Centrifugal Pump

Get Latest Price

Send Inquiry

| Model No. : | WN |

|---|---|

| Brand Name : | NNT |

Shijiazhuang Nainate Screens Pump Co., Ltd.

You might also like

Product description

Product Description Axial Split Case Double Suction Centrifugal Pump Construction 200WN to 500WN dredge pumps are of single casing, single stage cantilevered horizontal centrifugal pumps. Two types of coupling with gear box: frame and pump box. 600WN to 1000WN dredge pumps are of double casings, single stage cantilevered centrifugal pumps. These pumps are equipped with frame and lubrication is force thin oil. The design of double casing the pump working till the volute liner almost worn down and guarantee no leakage when volute liner is worn down.

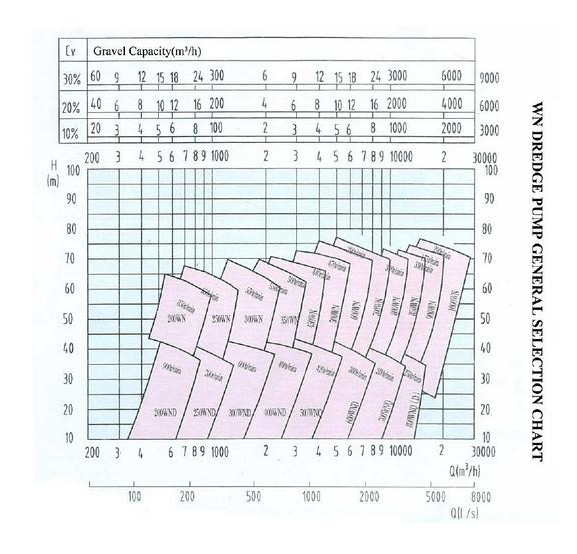

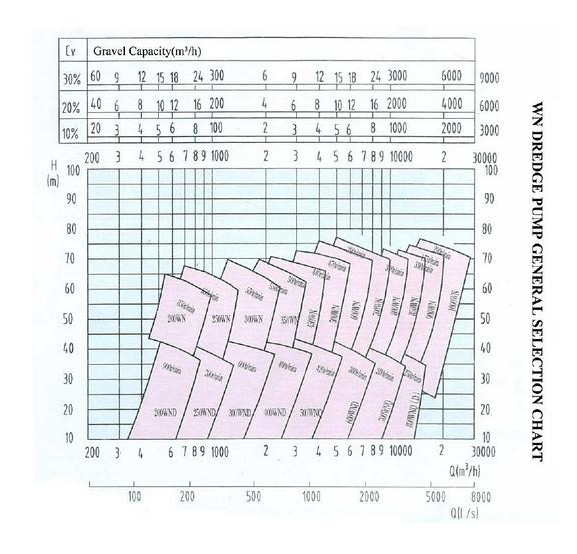

Easy Uninstallation & Convenient Maintenance WN dredge pump is of front uninstallation construction to make uninstall easily and convenient maintenance. And special tools are equipped for uninstalling the parts. Standard four-head trapezoid thread connection between impeller and shaft can transfer powerful torsion and be convenient to uninstall. Impeller uninstall ring at shaft sleeve side also make the impeller uninstallation much easier. Good Performance Good NPSH can not only guarantee suction but also make deep dredge and high allowable suction density. Minimum NPSH: 4m. With wide impeller passage, pump can continuously pump gravel or high plastic clay without clogging. Max allow particle size: 350mm. Performance curves descend obviously to make pumps adopt pipeline distance changes. By changing the impeller diameter or impeller rotating speed, it can easily change the discharge with the same flow rate.

Easy Uninstallation & Convenient Maintenance WN dredge pump is of front uninstallation construction to make uninstall easily and convenient maintenance. And special tools are equipped for uninstalling the parts. Standard four-head trapezoid thread connection between impeller and shaft can transfer powerful torsion and be convenient to uninstall. Impeller uninstall ring at shaft sleeve side also make the impeller uninstallation much easier. Good Performance Good NPSH can not only guarantee suction but also make deep dredge and high allowable suction density. Minimum NPSH: 4m. With wide impeller passage, pump can continuously pump gravel or high plastic clay without clogging. Max allow particle size: 350mm. Performance curves descend obviously to make pumps adopt pipeline distance changes. By changing the impeller diameter or impeller rotating speed, it can easily change the discharge with the same flow rate.

Material Material of wet parts is high wear resistant high chrome alloy. Considering the maintenance, wear resistant parts are nearly of the same wear life to reduce maintenance & interchange costs. Low Hydraulic loss, High efficiency, Energy Saving Efficiency of WN is 2 or 3 percentage higher than other common pumps. Reliable Shaft Seal, No leakage Shaft Seal types of 200WN to 500WN: Mechanical seal, packing, or combination of mechanical and packing 600WN to 1000WN uses helical casing L rubber seal which is made of 3 pieces of L seal ring and one special thread shaft sleeve.

Material Material of wet parts is high wear resistant high chrome alloy. Considering the maintenance, wear resistant parts are nearly of the same wear life to reduce maintenance & interchange costs. Low Hydraulic loss, High efficiency, Energy Saving Efficiency of WN is 2 or 3 percentage higher than other common pumps. Reliable Shaft Seal, No leakage Shaft Seal types of 200WN to 500WN: Mechanical seal, packing, or combination of mechanical and packing 600WN to 1000WN uses helical casing L rubber seal which is made of 3 pieces of L seal ring and one special thread shaft sleeve.

Turning 700WN to 1000WN can be equipped with turning to change rotating directions.

Turning 700WN to 1000WN can be equipped with turning to change rotating directions.  Features *Adopted high chrome impeller, suction cover and agitator as standard supplies. *High efficiency and quality motor in a rigid structure ensures long durability. * Adopted top quality mechanical seal. *Easy operation, handling and maintenance.

Features *Adopted high chrome impeller, suction cover and agitator as standard supplies. *High efficiency and quality motor in a rigid structure ensures long durability. * Adopted top quality mechanical seal. *Easy operation, handling and maintenance.  Applications *Dredging sand slurry gravel soil sludge mud paste mire slime slush at river, river mouth and sea floor *Transferring sand, slurry, gravel, soil, sludge at mine, civil works, construction sites, ready mixed concrete factory, Rock Wool Industrial ,Copper Mine Industrail, Petroleum Industrail, recruiting construction materials factory and power plant etc. *Removal sediment from sumps or basins.

Applications *Dredging sand slurry gravel soil sludge mud paste mire slime slush at river, river mouth and sea floor *Transferring sand, slurry, gravel, soil, sludge at mine, civil works, construction sites, ready mixed concrete factory, Rock Wool Industrial ,Copper Mine Industrail, Petroleum Industrail, recruiting construction materials factory and power plant etc. *Removal sediment from sumps or basins.  FAQ *Can you supply pump qualified with ANSI and ASME standard?

FAQ *Can you supply pump qualified with ANSI and ASME standard?

Yes, our pump compliant with ISO / ASME/ANSI standard. *How can I purchase order without seeing the quality first?

If it is a big order, we can provide a sample for running testing at your plant. *How do you control the quality of the products?

Our production is strictly according to ISO 9001 standard and factory was established in 1980, have over 30 years experience in slurry pumps and parts. *How to customize pumps and mechanical seals ?

Customers could send us application data, we will select suitable pump and seal types, or client could send us drawings, We are well in OEM and ODM. *How can I pay for my items? What is the payment you can provide?

Usually by T/T, 30% down payment once PI confirmed, the balance will be paid after inspection and before shipment.

L/C at sight *How long is warranty?

1 year for main construction warranty. *How long is production leading time?

Normally 25 days. If client need urgently, we have a huge spare parts stock, we could finish assembly and testing in 7-15 days. *What is the shipping terms you can provide ?

Depends on customer's requirements, we can provide different transportation terms, such as EXW, FOB, CIF. *Who is in charge of after-sales?

Inside sales. It can save customer's time and high efficiency communicate. NNT has professional after sales service team, we will follow up the client's comments and suggest them good solutions. Solve client's problems and keeping the clients profit. *Who is in charge of maintenance?

Local agent. Client is first, if pump running has any problem on site, our local agent will arrival the plant within 24 hours. About Nainater Shijiazhuang Nainater Slurry Pump Co., Ltd is a modern pump industry enterprise engages in professional manufactore, scientific research, develop, sales and service.

Our company is specialized in manufacturing: Slurry pump and Slurry pump parts, Dredging pump and Dredging pump parts, Desulfurization pump and Desulfurization pump parts, Clean water pump and Sewage pumps, are widely used in mine, metallurgy, coal, electric power ,dredge and other sectors of the national economy. These pumps are sold to South America, Africa, Southeast Asia, Russia and so on more than 20 countries and regions. Our products have won unanimous favorable comments from the market. The quality management systems of Nainater slurry pump are accredited to ISO 9001:2000 and our environmental management systems are accredited to ISO 14001:2004. Contact

Contact

Easy Uninstallation & Convenient Maintenance WN dredge pump is of front uninstallation construction to make uninstall easily and convenient maintenance. And special tools are equipped for uninstalling the parts. Standard four-head trapezoid thread connection between impeller and shaft can transfer powerful torsion and be convenient to uninstall. Impeller uninstall ring at shaft sleeve side also make the impeller uninstallation much easier. Good Performance Good NPSH can not only guarantee suction but also make deep dredge and high allowable suction density. Minimum NPSH: 4m. With wide impeller passage, pump can continuously pump gravel or high plastic clay without clogging. Max allow particle size: 350mm. Performance curves descend obviously to make pumps adopt pipeline distance changes. By changing the impeller diameter or impeller rotating speed, it can easily change the discharge with the same flow rate.

Easy Uninstallation & Convenient Maintenance WN dredge pump is of front uninstallation construction to make uninstall easily and convenient maintenance. And special tools are equipped for uninstalling the parts. Standard four-head trapezoid thread connection between impeller and shaft can transfer powerful torsion and be convenient to uninstall. Impeller uninstall ring at shaft sleeve side also make the impeller uninstallation much easier. Good Performance Good NPSH can not only guarantee suction but also make deep dredge and high allowable suction density. Minimum NPSH: 4m. With wide impeller passage, pump can continuously pump gravel or high plastic clay without clogging. Max allow particle size: 350mm. Performance curves descend obviously to make pumps adopt pipeline distance changes. By changing the impeller diameter or impeller rotating speed, it can easily change the discharge with the same flow rate.

Material Material of wet parts is high wear resistant high chrome alloy. Considering the maintenance, wear resistant parts are nearly of the same wear life to reduce maintenance & interchange costs. Low Hydraulic loss, High efficiency, Energy Saving Efficiency of WN is 2 or 3 percentage higher than other common pumps. Reliable Shaft Seal, No leakage Shaft Seal types of 200WN to 500WN: Mechanical seal, packing, or combination of mechanical and packing 600WN to 1000WN uses helical casing L rubber seal which is made of 3 pieces of L seal ring and one special thread shaft sleeve.

Material Material of wet parts is high wear resistant high chrome alloy. Considering the maintenance, wear resistant parts are nearly of the same wear life to reduce maintenance & interchange costs. Low Hydraulic loss, High efficiency, Energy Saving Efficiency of WN is 2 or 3 percentage higher than other common pumps. Reliable Shaft Seal, No leakage Shaft Seal types of 200WN to 500WN: Mechanical seal, packing, or combination of mechanical and packing 600WN to 1000WN uses helical casing L rubber seal which is made of 3 pieces of L seal ring and one special thread shaft sleeve.

Turning 700WN to 1000WN can be equipped with turning to change rotating directions.

Turning 700WN to 1000WN can be equipped with turning to change rotating directions.  Features *Adopted high chrome impeller, suction cover and agitator as standard supplies. *High efficiency and quality motor in a rigid structure ensures long durability. * Adopted top quality mechanical seal. *Easy operation, handling and maintenance.

Features *Adopted high chrome impeller, suction cover and agitator as standard supplies. *High efficiency and quality motor in a rigid structure ensures long durability. * Adopted top quality mechanical seal. *Easy operation, handling and maintenance.  Applications *Dredging sand slurry gravel soil sludge mud paste mire slime slush at river, river mouth and sea floor *Transferring sand, slurry, gravel, soil, sludge at mine, civil works, construction sites, ready mixed concrete factory, Rock Wool Industrial ,Copper Mine Industrail, Petroleum Industrail, recruiting construction materials factory and power plant etc. *Removal sediment from sumps or basins.

Applications *Dredging sand slurry gravel soil sludge mud paste mire slime slush at river, river mouth and sea floor *Transferring sand, slurry, gravel, soil, sludge at mine, civil works, construction sites, ready mixed concrete factory, Rock Wool Industrial ,Copper Mine Industrail, Petroleum Industrail, recruiting construction materials factory and power plant etc. *Removal sediment from sumps or basins.  FAQ *Can you supply pump qualified with ANSI and ASME standard?

FAQ *Can you supply pump qualified with ANSI and ASME standard?Yes, our pump compliant with ISO / ASME/ANSI standard. *How can I purchase order without seeing the quality first?

If it is a big order, we can provide a sample for running testing at your plant. *How do you control the quality of the products?

Our production is strictly according to ISO 9001 standard and factory was established in 1980, have over 30 years experience in slurry pumps and parts. *How to customize pumps and mechanical seals ?

Customers could send us application data, we will select suitable pump and seal types, or client could send us drawings, We are well in OEM and ODM. *How can I pay for my items? What is the payment you can provide?

Usually by T/T, 30% down payment once PI confirmed, the balance will be paid after inspection and before shipment.

L/C at sight *How long is warranty?

1 year for main construction warranty. *How long is production leading time?

Normally 25 days. If client need urgently, we have a huge spare parts stock, we could finish assembly and testing in 7-15 days. *What is the shipping terms you can provide ?

Depends on customer's requirements, we can provide different transportation terms, such as EXW, FOB, CIF. *Who is in charge of after-sales?

Inside sales. It can save customer's time and high efficiency communicate. NNT has professional after sales service team, we will follow up the client's comments and suggest them good solutions. Solve client's problems and keeping the clients profit. *Who is in charge of maintenance?

Local agent. Client is first, if pump running has any problem on site, our local agent will arrival the plant within 24 hours. About Nainater Shijiazhuang Nainater Slurry Pump Co., Ltd is a modern pump industry enterprise engages in professional manufactore, scientific research, develop, sales and service.

Our company is specialized in manufacturing: Slurry pump and Slurry pump parts, Dredging pump and Dredging pump parts, Desulfurization pump and Desulfurization pump parts, Clean water pump and Sewage pumps, are widely used in mine, metallurgy, coal, electric power ,dredge and other sectors of the national economy. These pumps are sold to South America, Africa, Southeast Asia, Russia and so on more than 20 countries and regions. Our products have won unanimous favorable comments from the market. The quality management systems of Nainater slurry pump are accredited to ISO 9001:2000 and our environmental management systems are accredited to ISO 14001:2004.

Contact

Contact

Send your inquiry to this supplier

Send Inquiry