1 / 6

Automatic Self Cleaning Industrial Water Filter for Treatment Process Water Filtration

Get Latest Price

Send Inquiry

| Model No. : | A500 |

|---|---|

| Brand Name : | AIGER |

Beijing Zhongyuantong Science and Technology Co.,Ltd.

You might also like

Product description

Automatic Self Cleaning Industrial Water Filter for Treatment Process Water Filtration Brief Introduction: The AIGER500 series automatic filters for water treatment is a horizontal electric brush type filter screen structure, wedge type 316 stainless steel. It is suitable for harsh environment, high oil content, dirt load in the water, single machine processing flow is 2400 m³/h. The motor driven stainless steel brush is rotating in the filter body to clean the dirt on screen, cleaning dirt, the pollutant through the drain valve.  Working Principle: Liquid into the filter via the water inlet, Impurities is deposited on the stainless steel mesh, Filtered clean water from the outlet flow out, With the accumulation of impurities inside the cartridge, the filter cake formed in the surface of the cartridge, which leads to gradually pressure , drop increasing between the inlet and outlet ,it begin the automatic cleaning process, when the pressure reaches the default . The automatic self cleaning finished by rotating cleaning brush and switching the drain valve .open the drain valve is blocked so that a negative pressure within the cartridge, the cartridge attached to the inner wall of the filter cake was cleaning brush cleaning off the relationship because of negative pressure through the sewage discharge valve in this body. The cleaning process is within 60 seconds, the system continues to flow cleaning. Model and Specification:

Working Principle: Liquid into the filter via the water inlet, Impurities is deposited on the stainless steel mesh, Filtered clean water from the outlet flow out, With the accumulation of impurities inside the cartridge, the filter cake formed in the surface of the cartridge, which leads to gradually pressure , drop increasing between the inlet and outlet ,it begin the automatic cleaning process, when the pressure reaches the default . The automatic self cleaning finished by rotating cleaning brush and switching the drain valve .open the drain valve is blocked so that a negative pressure within the cartridge, the cartridge attached to the inner wall of the filter cake was cleaning brush cleaning off the relationship because of negative pressure through the sewage discharge valve in this body. The cleaning process is within 60 seconds, the system continues to flow cleaning. Model and Specification:

Note:Our company can produce the filter according to the user required size, material (such as: carbon steel, stainless steel), color (red, yellow, blue, green) and other special requirements.  Technical Parameter: • Filter flow: 80-2000 m3/h

Technical Parameter: • Filter flow: 80-2000 m3/h

• Pressure rating:1.0Mpa/1.6Mpa/2.5Mpa

• Working temperature range:0~65℃

• Filtering precision:50-3000micron

• Pressure loss:<0.01 Mpa

• Inlet and outlet Connection: flange

• Backwash time: 20~30 sec

• Filter screen: 304 SS wedge screen

• Water usage during backwash cycle: 1%~3% of filtered water

• Control mode: DP control/PLC timing control/manual

• Drive way: motor drive

• Cleaning mode: suction nozzle

• Rated operating voltage:3-ph, 380v,

1-ph,220v,50Hz

• Filter housing: carbon steel Installation and Site Picture:

Spare Parts: AIGER 500 Series automatic backwash water filter consist of Motor, Electric control boxes, Control line (including the Control valve and Differential pressure controller), Pipeline elements , filter elements, 316L Stainless steel brush, Frame elements,Framework components, Connecting flanges and Other major components

Spare Parts: AIGER 500 Series automatic backwash water filter consist of Motor, Electric control boxes, Control line (including the Control valve and Differential pressure controller), Pipeline elements , filter elements, 316L Stainless steel brush, Frame elements,Framework components, Connecting flanges and Other major components

Packing&Shipping:

Packing&Shipping:  Application: Water treating, Raw water treating , Recycle water , Chilling water treat Agricultural irrigation ,such as Farms Water , Golf Water Filtration , Orchards and Groves Water Filtration , Vineyard Water Filtration etc . Papermaking factory Steel and lron plant Petroleum Chemistry

Application: Water treating, Raw water treating , Recycle water , Chilling water treat Agricultural irrigation ,such as Farms Water , Golf Water Filtration , Orchards and Groves Water Filtration , Vineyard Water Filtration etc . Papermaking factory Steel and lron plant Petroleum Chemistry  Company Information: Beijing ZhongYuanTong Science and Technology Co., Ltd. founded in 1998, we have strong technical research and development strength, excellent production capacity and high quality after sale service to win a majority of customers trust and support. Number of Staff: 120 persons, R&D staff account for 50%. Including 2 Ph.Ds, 9 Masters and 15 senior technical engineers.

Company Information: Beijing ZhongYuanTong Science and Technology Co., Ltd. founded in 1998, we have strong technical research and development strength, excellent production capacity and high quality after sale service to win a majority of customers trust and support. Number of Staff: 120 persons, R&D staff account for 50%. Including 2 Ph.Ds, 9 Masters and 15 senior technical engineers.  Why do you choose us?

Why do you choose us?

1) Professional technology support

2) 1 years quality guarantee, All products 100% tested

3) Delivery in time

4) Most competitive price

5) Many years production and sales experience

6) Commitment to our customers, Friendly staff

Working Principle: Liquid into the filter via the water inlet, Impurities is deposited on the stainless steel mesh, Filtered clean water from the outlet flow out, With the accumulation of impurities inside the cartridge, the filter cake formed in the surface of the cartridge, which leads to gradually pressure , drop increasing between the inlet and outlet ,it begin the automatic cleaning process, when the pressure reaches the default . The automatic self cleaning finished by rotating cleaning brush and switching the drain valve .open the drain valve is blocked so that a negative pressure within the cartridge, the cartridge attached to the inner wall of the filter cake was cleaning brush cleaning off the relationship because of negative pressure through the sewage discharge valve in this body. The cleaning process is within 60 seconds, the system continues to flow cleaning. Model and Specification:

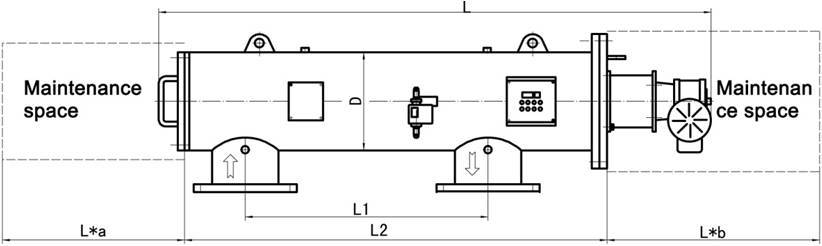

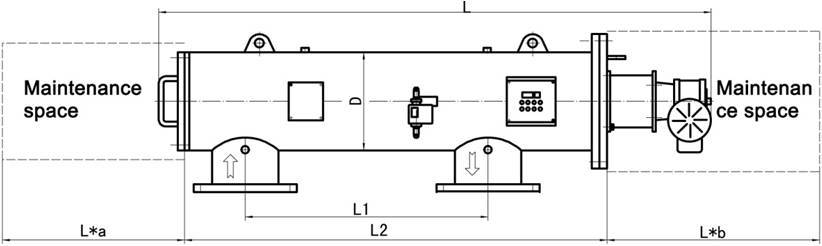

Working Principle: Liquid into the filter via the water inlet, Impurities is deposited on the stainless steel mesh, Filtered clean water from the outlet flow out, With the accumulation of impurities inside the cartridge, the filter cake formed in the surface of the cartridge, which leads to gradually pressure , drop increasing between the inlet and outlet ,it begin the automatic cleaning process, when the pressure reaches the default . The automatic self cleaning finished by rotating cleaning brush and switching the drain valve .open the drain valve is blocked so that a negative pressure within the cartridge, the cartridge attached to the inner wall of the filter cake was cleaning brush cleaning off the relationship because of negative pressure through the sewage discharge valve in this body. The cleaning process is within 60 seconds, the system continues to flow cleaning. Model and Specification: Model | Flow (m³/h) | DN(mm) | Weight (kg) | D | L | H | L1 | L2 | L*a | L*b |

A504 | 80 | 100 | 180 | 325 | 1255 | 507.5 | 450 | 827 | 350 | 600 |

A506 | 150 | 150 | 190 | 325 | 1330 | 507.5 | 500 | 902 | 400 | 600 |

A508 | 300 | 200 | 235 | 325 | 1820 | 522.5 | 800 | 1392 | 600 | 900 |

A510 | 400 | 250 | 340 | 426 | 1915 | 622.5 | 800 | 1482 | 700 | 900 |

A512 | 600 | 300 | 415 | 426 | 2525 | 632.5 | 1100 | 2092 | 1100 | 1200 |

A514 | 900 | 350 | 530 | 530 | 2525 | 735 | 1100 | 2092 | 1100 | 1200 |

A516 | 1100 | 400 | 550 | 530 | 2525 | 745 | 1100 | 2092 | 1100 | 1200 |

A518 | 1500 | 450 | 1020 | 720 | 2550 | 977.5 | 1100 | 2107 | 1100 | 1200 |

Technical Parameter: • Filter flow: 80-2000 m3/h

Technical Parameter: • Filter flow: 80-2000 m3/h• Pressure rating:1.0Mpa/1.6Mpa/2.5Mpa

• Working temperature range:0~65℃

• Filtering precision:50-3000micron

• Pressure loss:<0.01 Mpa

• Inlet and outlet Connection: flange

• Backwash time: 20~30 sec

• Filter screen: 304 SS wedge screen

• Water usage during backwash cycle: 1%~3% of filtered water

• Control mode: DP control/PLC timing control/manual

• Drive way: motor drive

• Cleaning mode: suction nozzle

• Rated operating voltage:3-ph, 380v,

1-ph,220v,50Hz

• Filter housing: carbon steel Installation and Site Picture:

Spare Parts: AIGER 500 Series automatic backwash water filter consist of Motor, Electric control boxes, Control line (including the Control valve and Differential pressure controller), Pipeline elements , filter elements, 316L Stainless steel brush, Frame elements,Framework components, Connecting flanges and Other major components

Spare Parts: AIGER 500 Series automatic backwash water filter consist of Motor, Electric control boxes, Control line (including the Control valve and Differential pressure controller), Pipeline elements , filter elements, 316L Stainless steel brush, Frame elements,Framework components, Connecting flanges and Other major components

Packing&Shipping:

Packing&Shipping:  Application: Water treating, Raw water treating , Recycle water , Chilling water treat Agricultural irrigation ,such as Farms Water , Golf Water Filtration , Orchards and Groves Water Filtration , Vineyard Water Filtration etc . Papermaking factory Steel and lron plant Petroleum Chemistry

Application: Water treating, Raw water treating , Recycle water , Chilling water treat Agricultural irrigation ,such as Farms Water , Golf Water Filtration , Orchards and Groves Water Filtration , Vineyard Water Filtration etc . Papermaking factory Steel and lron plant Petroleum Chemistry  Company Information: Beijing ZhongYuanTong Science and Technology Co., Ltd. founded in 1998, we have strong technical research and development strength, excellent production capacity and high quality after sale service to win a majority of customers trust and support. Number of Staff: 120 persons, R&D staff account for 50%. Including 2 Ph.Ds, 9 Masters and 15 senior technical engineers.

Company Information: Beijing ZhongYuanTong Science and Technology Co., Ltd. founded in 1998, we have strong technical research and development strength, excellent production capacity and high quality after sale service to win a majority of customers trust and support. Number of Staff: 120 persons, R&D staff account for 50%. Including 2 Ph.Ds, 9 Masters and 15 senior technical engineers.  Why do you choose us?

Why do you choose us?1) Professional technology support

2) 1 years quality guarantee, All products 100% tested

3) Delivery in time

4) Most competitive price

5) Many years production and sales experience

6) Commitment to our customers, Friendly staff

Send your inquiry to this supplier

Send Inquiry