1 / 1

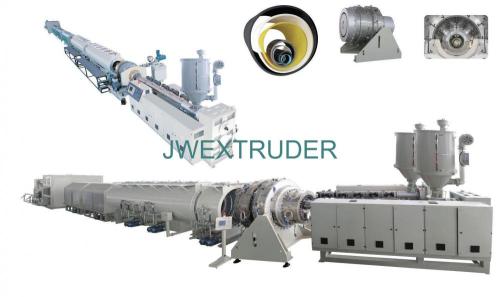

Automatic high performance pipe extrusion line

| Brand Name : | jwextruder |

|---|

Product description

Automatic high performance pipe extrusion line

Both the main extruder and downstream equipment are integrated and synchronized. Complete automatic control system is installed for the production system, easy to operate and efficient, high quality machinery components to ensure high reliability and long lasting.

Advantages of JWExtruder Technologies for different types of Pipes Manufacture:

PLC control for the entire line;

The high volume, low melting temperature;

Special screw design, high efficiency, high yield;

Helical gear: high hardness, low noise, with reliable performance and long service life;

Different extruder can be replaced according to the type of raw material.

Die head

Polyolefin pipe die head

Standard series: 10-630mm. Screw-type: distribution or blue bypass, provide sufficient melt flow space and melting period;

Minimize internal stress, ensure pipe`s internal and external smooth surface;

High flexibility, applies to all co-extrusion of polyolefin materials (double/triple/quadruple layers).

PVC pipe die head

Standard series: pipe range10-630mm;

Heating temperature distributes evenly;

Special deisgned molds for reducing mold changing and replacement time.

Calibrating sleeve

Polyolefin pipe calibrating sleeve

Equip with water inlet-channel (made of special copper alloys), suitable for HDPE, MDPE, LDPE, LLDPE, PP etc. raw material extrusion;

Before the inlet-channel entrance there is was a closed section, pipes going through this section would be fully dipped in cooling water, especially suitable for small diameter pipe extrusion.

PVC pipe calibrating sleeve

Before the inlet-channel entrance there is installed with pre-cooling device, to meet high-speed extrusion requirement;

Vacuum calibrating tank

Made of stainless steel;

High power water pumps and specially designed spray head brings high efficiency spraying & cooling;

Dense amount of spray head layout in calibrating sleeve location;

To prevent water impurities that clogging pipes and spray heads, filtration unit is installed;

High and low water level control device;

Plexiglas safety cover;

Optional equipment for twin pipe extrusion.

Hall-off unit

2-caterpillars or multi-caterpillars hall-off unit;

Via proportional valves and pressure control, can adjust the contact pressure can be adjusted precisely;

High degree of synchronization.

Cutting unit

Saw blade type, planetary type, ring-type and no-scraps type cutting machine to choose from`

Length fixated auto-cutting function;

Tracking the pipe`s length then cutting, fully synchronized;

Low noise and high level of safety protection design.

Send your inquiry to this supplier