1 / 6

Automatic glass bottle vacuum sealing machine

Get Latest Price

Send Inquiry

| Model No. : | BPY50/500-500 Glass Bottle IV Solution Production Line |

|---|---|

| Brand Name : | FE |

Hunan FE Pharmaceutical Machinery Co., Ltd.

You might also like

Product description

Automatic glass bottle vacuum sealing machine Product Description

Automatic glass bottle vacuum sealing machine is suitable for 50ml, 100ml, 250ml, 500ml and 1,000 ml glass bottle IV-solution producing. The whole line is made up of washing, filling and capping machines, it can automatically finish the procedure such as bottle-collating, rough/ fine washing for inside and outside of bottle, filling, plug-pressuring, cap-collating, cap-jamming and cap – rolling, lamp checking, labeling etc. This production line is also suitable for other liquid medicine washing, filling and sealing producing, such as tincture syrup, oral liquid etc. Product Detail Product Detail Main Features 1.Automatic glass bottle vacuum sealing machine with series connection mode, the structure is clear and appearance is elegant.The line can be separate in different purified class section. Buffer area is setted so the bottle deliver dose not cross area, which totally confirm to the requirements of GMP. 2. The line can made like this: fine cleaning & filling in one machine or filling & stoppering in one machine.Then the line will be short, need less space and less operator. 3. Rough washing and fine washing are totally separate and finished in 2 machines, avoid the cross contamination. 4. Bottle washing machine applies modern structure, roug cleaning adopts the same place for bottle input and output. This saves operator and space. At the same time, both the rough cleaning and fine cleaning machine adopt twice bottle recieving technology, which solves the problem of bottle collapsed and broken. 5. Rough washing adopts the box type ultrasonic bottle washing, thoroughly overcoming the brush hair slipping, bottles broken, dead area etc. Moreover, the bottle stays in ultrasonic water for a long time, can reach the requirements of thorough degreasing and decontamination. Good cleaning effect and the low bottle breakage rate. 6. The bottle washing machine uses the intermittent rinsing, avoiding the cross contamination caused by continuous rinsing. 7.Rinsing water can be recycled in the lower class, decreasing the water consumption. 8. The filling adopts the theory of constant time and current, the filling quantity is adjusted by the computer with accurate measurement. No bottle, no filling, completely avoid the funnel -like defects. And can realize the CIP/SIP. 9. The production line is with high degree of automation, need less operator, low laboring use, high general use, easy specifications changing. Product Parameters

Main Features 1.Automatic glass bottle vacuum sealing machine with series connection mode, the structure is clear and appearance is elegant.The line can be separate in different purified class section. Buffer area is setted so the bottle deliver dose not cross area, which totally confirm to the requirements of GMP. 2. The line can made like this: fine cleaning & filling in one machine or filling & stoppering in one machine.Then the line will be short, need less space and less operator. 3. Rough washing and fine washing are totally separate and finished in 2 machines, avoid the cross contamination. 4. Bottle washing machine applies modern structure, roug cleaning adopts the same place for bottle input and output. This saves operator and space. At the same time, both the rough cleaning and fine cleaning machine adopt twice bottle recieving technology, which solves the problem of bottle collapsed and broken. 5. Rough washing adopts the box type ultrasonic bottle washing, thoroughly overcoming the brush hair slipping, bottles broken, dead area etc. Moreover, the bottle stays in ultrasonic water for a long time, can reach the requirements of thorough degreasing and decontamination. Good cleaning effect and the low bottle breakage rate. 6. The bottle washing machine uses the intermittent rinsing, avoiding the cross contamination caused by continuous rinsing. 7.Rinsing water can be recycled in the lower class, decreasing the water consumption. 8. The filling adopts the theory of constant time and current, the filling quantity is adjusted by the computer with accurate measurement. No bottle, no filling, completely avoid the funnel -like defects. And can realize the CIP/SIP. 9. The production line is with high degree of automation, need less operator, low laboring use, high general use, easy specifications changing. Product Parameters

Factory Show  Our Team Our Team

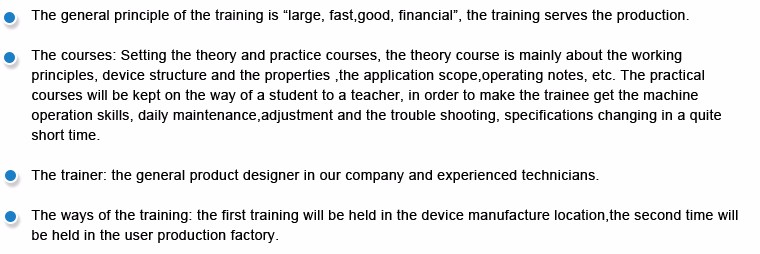

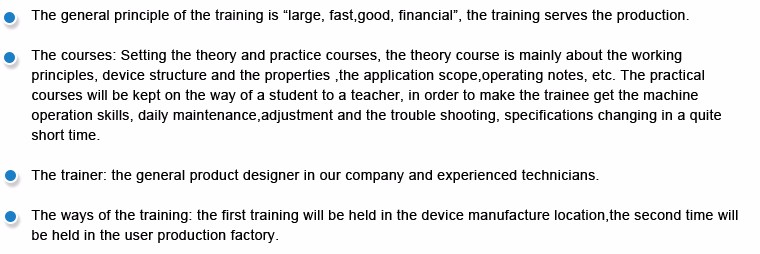

Our Team Our Team  Operation Training Operation Training

Operation Training Operation Training  Exhibitions Exhibitions

Exhibitions Exhibitions  Cooperative Client Cooperative Client

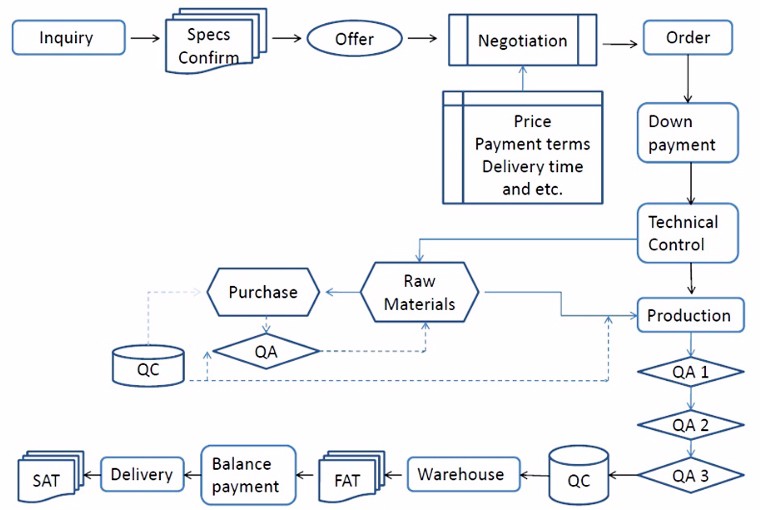

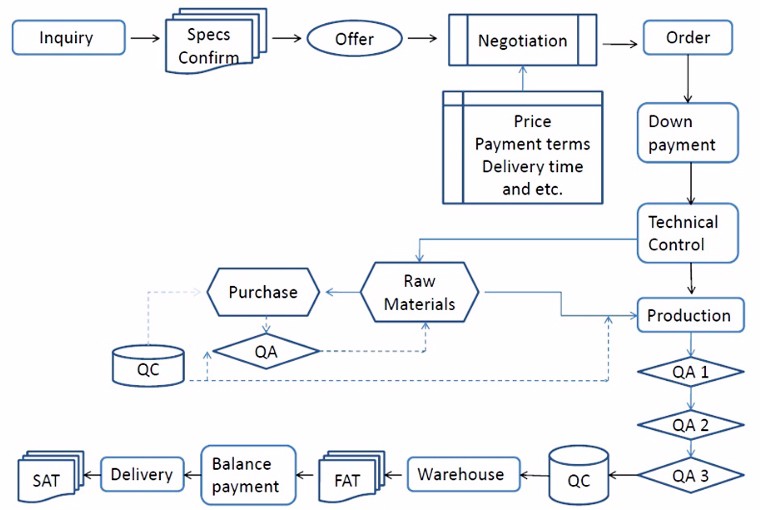

Cooperative Client Cooperative Client  Package and Shipping Order Service Process

Package and Shipping Order Service Process  Order Service Process

Order Service Process

Automatic glass bottle vacuum sealing machine is suitable for 50ml, 100ml, 250ml, 500ml and 1,000 ml glass bottle IV-solution producing. The whole line is made up of washing, filling and capping machines, it can automatically finish the procedure such as bottle-collating, rough/ fine washing for inside and outside of bottle, filling, plug-pressuring, cap-collating, cap-jamming and cap – rolling, lamp checking, labeling etc. This production line is also suitable for other liquid medicine washing, filling and sealing producing, such as tincture syrup, oral liquid etc. Product Detail Product Detail

Main Features 1.Automatic glass bottle vacuum sealing machine with series connection mode, the structure is clear and appearance is elegant.The line can be separate in different purified class section. Buffer area is setted so the bottle deliver dose not cross area, which totally confirm to the requirements of GMP. 2. The line can made like this: fine cleaning & filling in one machine or filling & stoppering in one machine.Then the line will be short, need less space and less operator. 3. Rough washing and fine washing are totally separate and finished in 2 machines, avoid the cross contamination. 4. Bottle washing machine applies modern structure, roug cleaning adopts the same place for bottle input and output. This saves operator and space. At the same time, both the rough cleaning and fine cleaning machine adopt twice bottle recieving technology, which solves the problem of bottle collapsed and broken. 5. Rough washing adopts the box type ultrasonic bottle washing, thoroughly overcoming the brush hair slipping, bottles broken, dead area etc. Moreover, the bottle stays in ultrasonic water for a long time, can reach the requirements of thorough degreasing and decontamination. Good cleaning effect and the low bottle breakage rate. 6. The bottle washing machine uses the intermittent rinsing, avoiding the cross contamination caused by continuous rinsing. 7.Rinsing water can be recycled in the lower class, decreasing the water consumption. 8. The filling adopts the theory of constant time and current, the filling quantity is adjusted by the computer with accurate measurement. No bottle, no filling, completely avoid the funnel -like defects. And can realize the CIP/SIP. 9. The production line is with high degree of automation, need less operator, low laboring use, high general use, easy specifications changing. Product Parameters

Main Features 1.Automatic glass bottle vacuum sealing machine with series connection mode, the structure is clear and appearance is elegant.The line can be separate in different purified class section. Buffer area is setted so the bottle deliver dose not cross area, which totally confirm to the requirements of GMP. 2. The line can made like this: fine cleaning & filling in one machine or filling & stoppering in one machine.Then the line will be short, need less space and less operator. 3. Rough washing and fine washing are totally separate and finished in 2 machines, avoid the cross contamination. 4. Bottle washing machine applies modern structure, roug cleaning adopts the same place for bottle input and output. This saves operator and space. At the same time, both the rough cleaning and fine cleaning machine adopt twice bottle recieving technology, which solves the problem of bottle collapsed and broken. 5. Rough washing adopts the box type ultrasonic bottle washing, thoroughly overcoming the brush hair slipping, bottles broken, dead area etc. Moreover, the bottle stays in ultrasonic water for a long time, can reach the requirements of thorough degreasing and decontamination. Good cleaning effect and the low bottle breakage rate. 6. The bottle washing machine uses the intermittent rinsing, avoiding the cross contamination caused by continuous rinsing. 7.Rinsing water can be recycled in the lower class, decreasing the water consumption. 8. The filling adopts the theory of constant time and current, the filling quantity is adjusted by the computer with accurate measurement. No bottle, no filling, completely avoid the funnel -like defects. And can realize the CIP/SIP. 9. The production line is with high degree of automation, need less operator, low laboring use, high general use, easy specifications changing. Product Parameters Model | BPY50/500-120 | BPY50/500-200 | BPY50/500-300 | BPY50/500-600 |

|

Applied bottle size | 50ml, 100ml, 250ml, 500ml, 1000ml | ||||

Capacity | 80-120 bottle/min | 120-200bottle/min | 200-300bottle/min | 300-600bottle/min | |

Electric capacity | 35KW | 37KW | 45KW | 55KW | |

| Pressed air consumption | 4 m³/h (0.6MPa) | 5 m³/h (0.6MPa) | 6 m³/h (0.6MPa) | 7 m³/h (0.6MPa) | |

| Water consumption | Tap water:200ml/ bottle; purified water:80ml/ bottle; Injection water:100ml/ bottle 0.2MPa | ||||

Outer dimension(mm) | 17800X6000X2300 | 19000X6000X2300 | 24000X7000X2300 | 24000X7000X2300 | |

Our Team Our Team

Our Team Our Team  Operation Training Operation Training

Operation Training Operation Training  Exhibitions Exhibitions

Exhibitions Exhibitions  Cooperative Client Cooperative Client

Cooperative Client Cooperative Client  Package and Shipping Order Service Process

Package and Shipping Order Service Process  Order Service Process

Order Service Process

Send your inquiry to this supplier

Send Inquiry